Backing ring made from red copper in use for plasma arc welding sheet metal and fabricating method

A technology of plasma arc and manufacturing method, applied in the field of red copper backing ring and its manufacturing, can solve the problems of difficult machining, increase production cost, waste metal and energy, etc., and achieve the effects of good quality, improved effect and saving processing cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

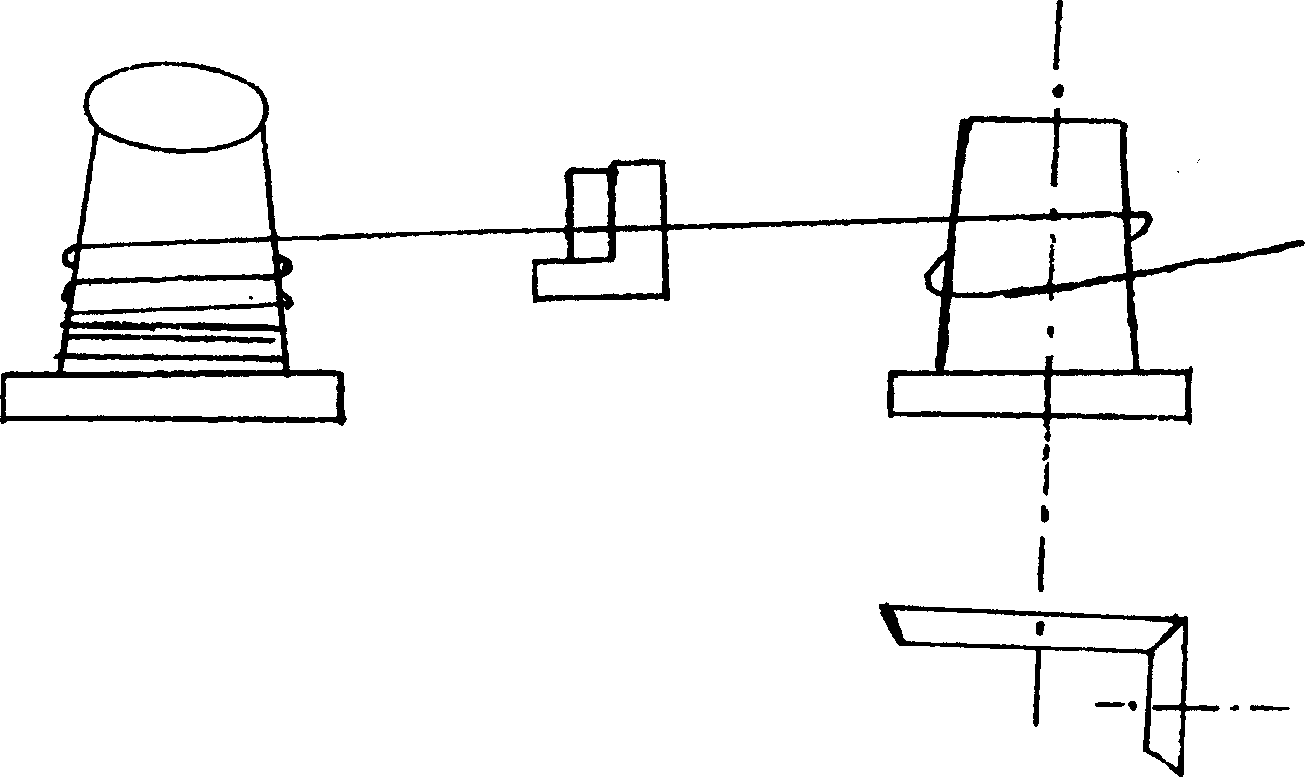

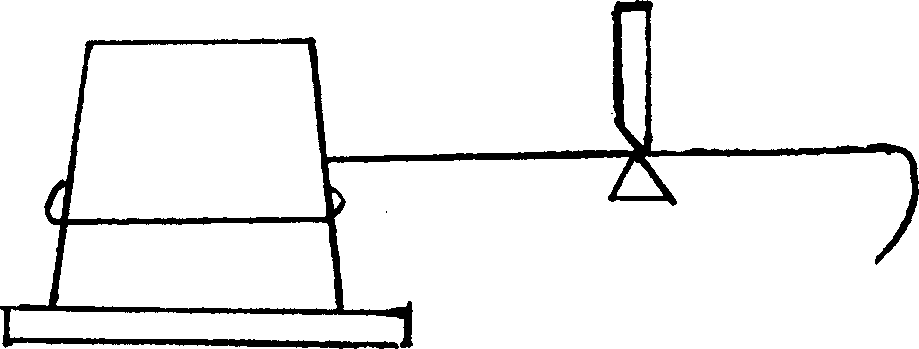

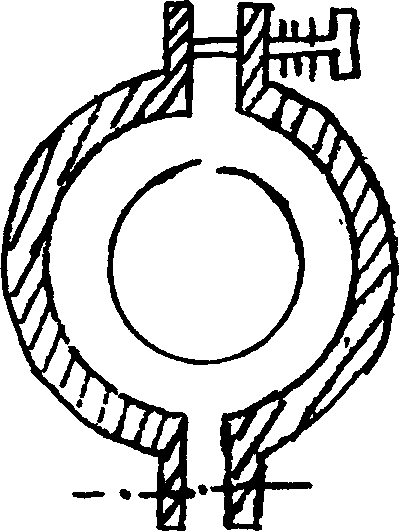

[0017] The present invention will be further described below in conjunction with accompanying drawing.

[0018] A method for manufacturing a red copper backing ring for plasma arc welding of a thin plate is characterized in that it comprises the following steps:

[0019] a. Put the copper wire with a diameter of 2-4mm on the roller of the stretching machine;

[0020] b. After the red copper wire is stretched through the drawing die for multiple passes, the red copper backing ring blank wire is obtained;

[0021] c. The red copper backing ring blank line is cut into a specified length of red copper backing ring blank line with a cutting device;

[0022] d. Put the red copper forming backing ring blank line on the straightening device for correction to obtain the finished red copper forming backing ring.

[0023] The number of stretching times in the above step b on the stretching machine is 3-6 times.

[0024] Copper backing ring for thin plate plasma arc welding, the copper...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com