Paper shredder cutter and processing method thereof

A processing method and paper shredder technology, applied to wire processing, household appliances, and other household appliances, can solve problems such as poor workmanship, increased cost, and poor rigidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

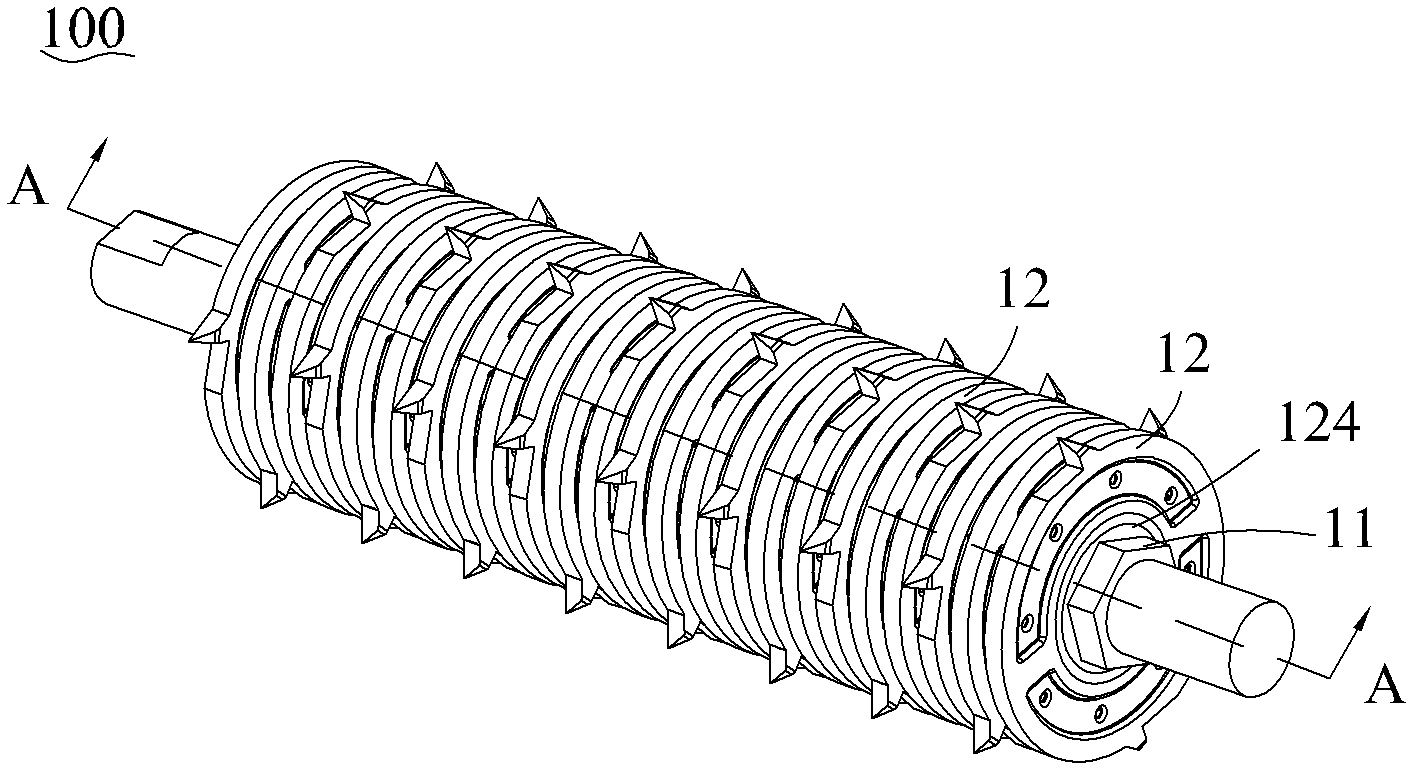

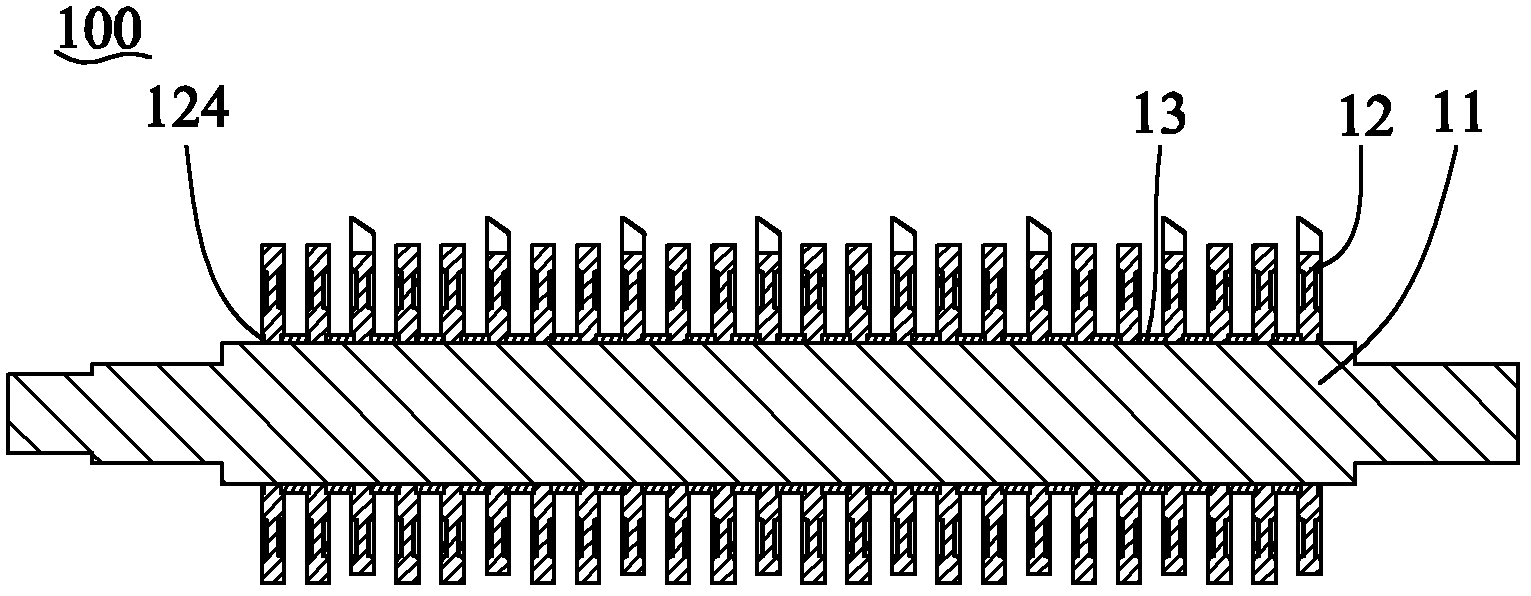

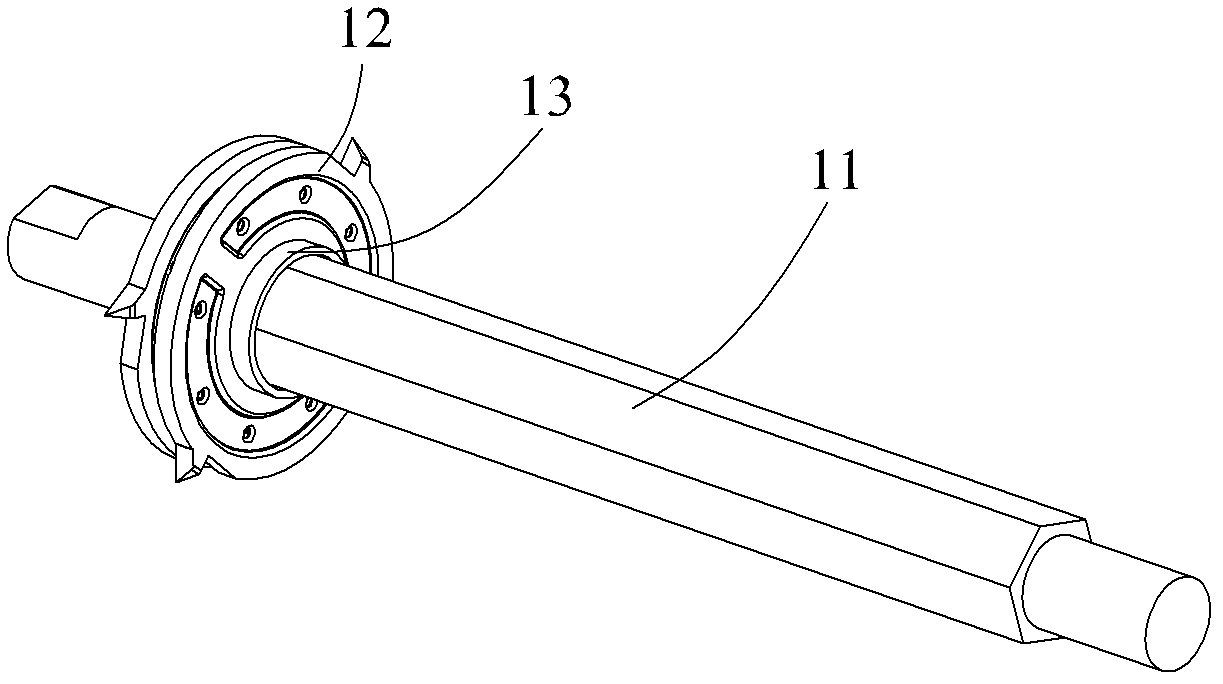

[0033] reference Figure 1 to Figure 12 , The paper shredder cutter 100 of the present invention includes a cutter shaft 11, blades 12 arranged at a certain interval on the cutter shaft 11, and a metal spacer ring 13 arranged between every two blades 12 to separate the two blades 12 , The metal spacer ring 13 is cut from a metal strip.

[0034] Specifically, refer to Figure 1 to Figure 6 In the first embodiment of the present invention, the metal spacer ring 13 is formed by coiling and cutting flat metal wires.

[0035] Specifically, refer to Figure 7 to Figure 12 In the second embodiment of the present invention, the metal spacer ring 13 is formed by coiling and cutting round metal wires.

[0036] reference Figure 4 to Figure 6 , Figure 10 to Figure 12 The blade 12 includes a blade body 121, a mounting hole 122 at the center of the blade body 121, and a plurality of blades 123 at the edge of the blade body 121. Preferably, the blade 12 is provided with a limiting groove 124 co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com