Steel wire ring disassembling device for winding machine

A technology of traveler and winding machine, which is applied in the direction of manufacturing rings, other household appliances, household appliances, etc. from wires, can solve the problems of messy and interlaced traveler, reduce overall efficiency, and affect product quality, so as to avoid interference and improve production efficiency. , The effect of easy mechanical removal

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail:

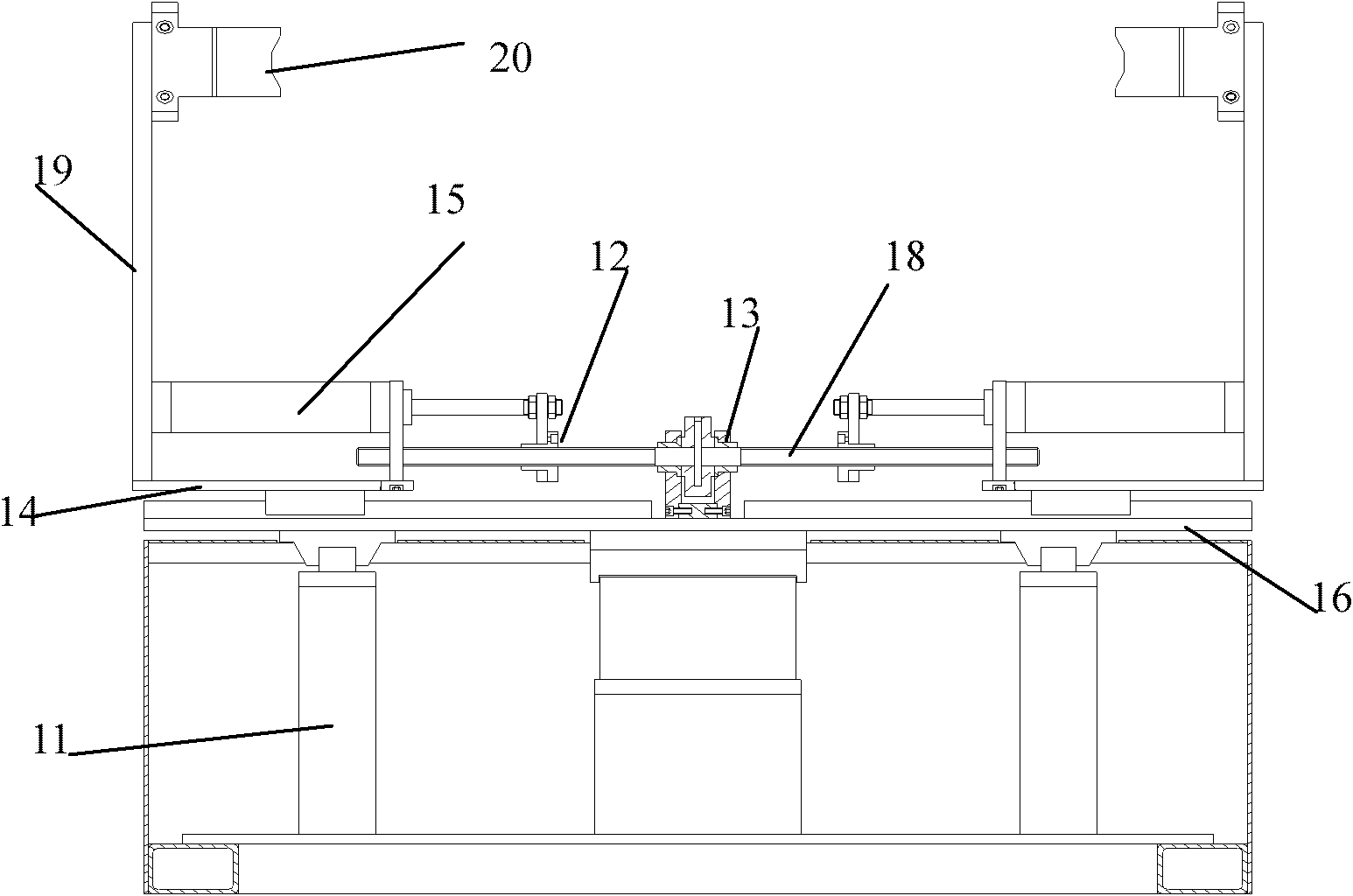

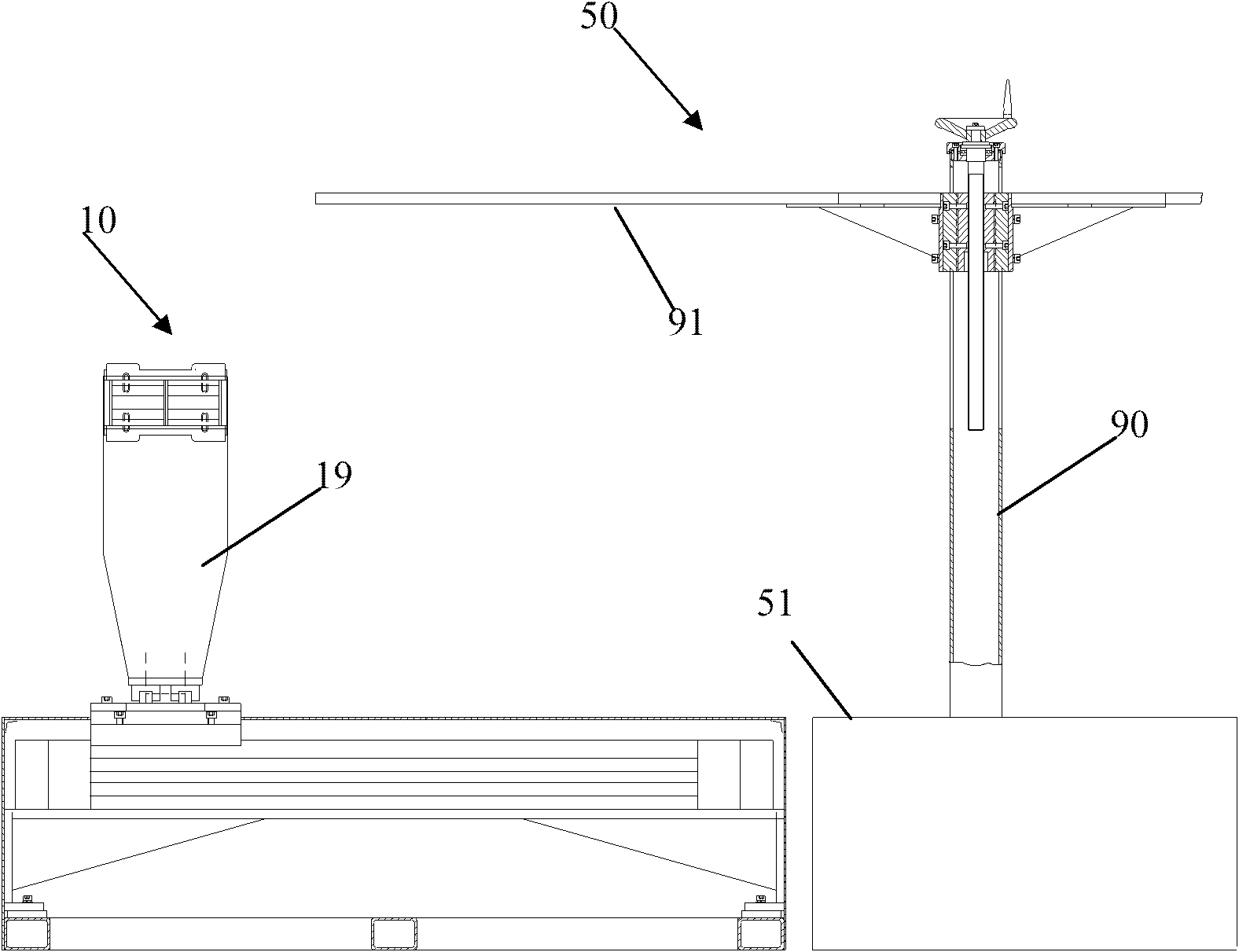

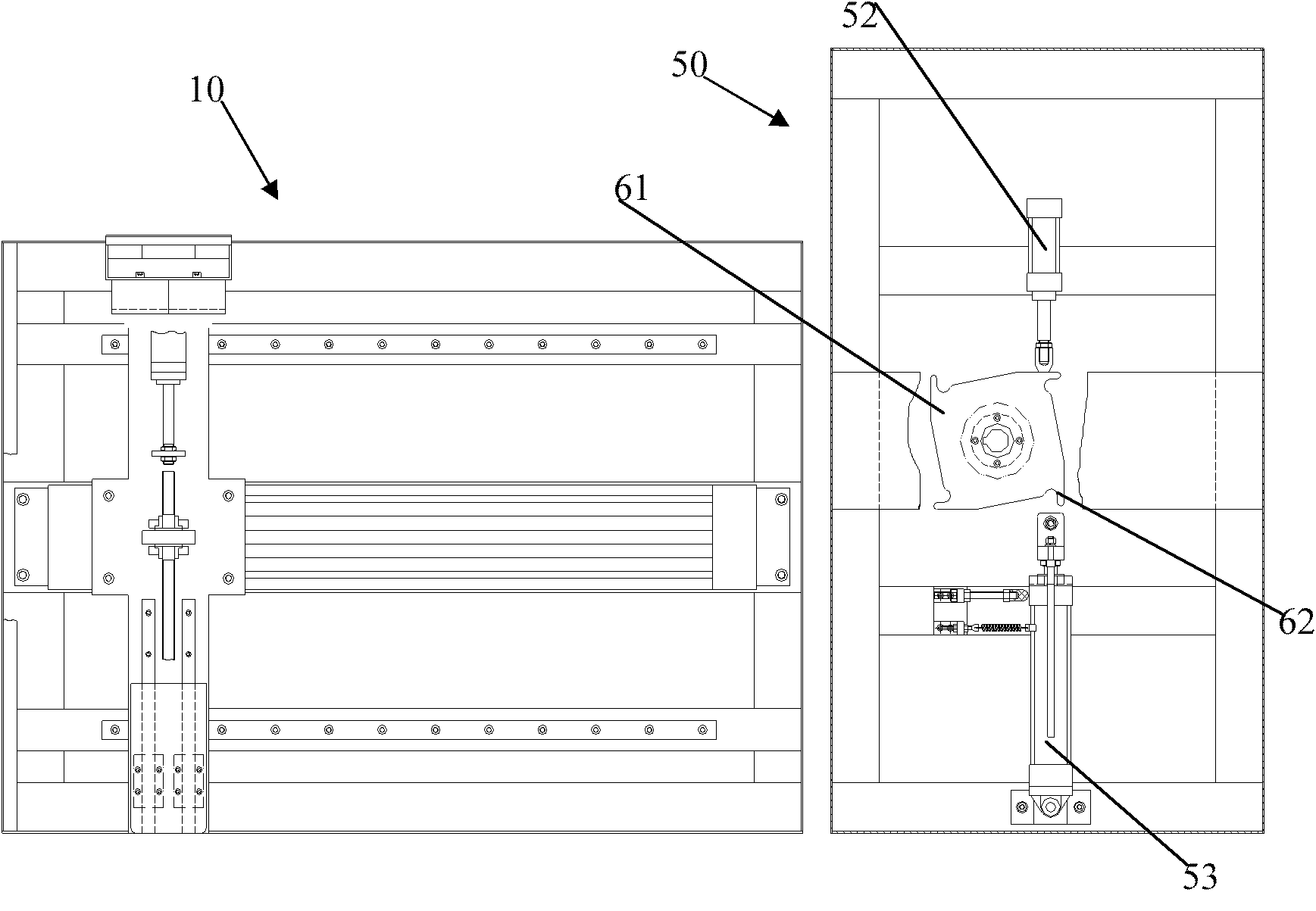

[0024] Such as Figure 1-3 As shown, the traveler unloading device of the present invention includes two parts: a ring taking device 10 and a ring receiving device 50. The ring taking device 10 includes a base 11, a movable bottom plate 16 that can be longitudinally slidably arranged on the base 11, The two left and right movable support plates 14 that can be horizontally slidably arranged above the movable bottom plate 16, the circle-taking cylinder 15 is arranged between the described movable support plate 14 and the movable bottom plate 16, and the outer sides of the two movable support plates 14 are fixedly connected with vertical The ring-taking arm 19, the bead ring clamping part 20 inside the upper end of the ring-taking arm 19, the clamping part 20 gathers or separates under the control of the ring-taking cylinder to complete the pick-up...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com