Method of and a device for producing parts

a technology for producing parts and devices, applied in the direction of manufacturing tools, auxillary welding devices, soldering devices, etc., can solve the problems of inconvenient and expensiv

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

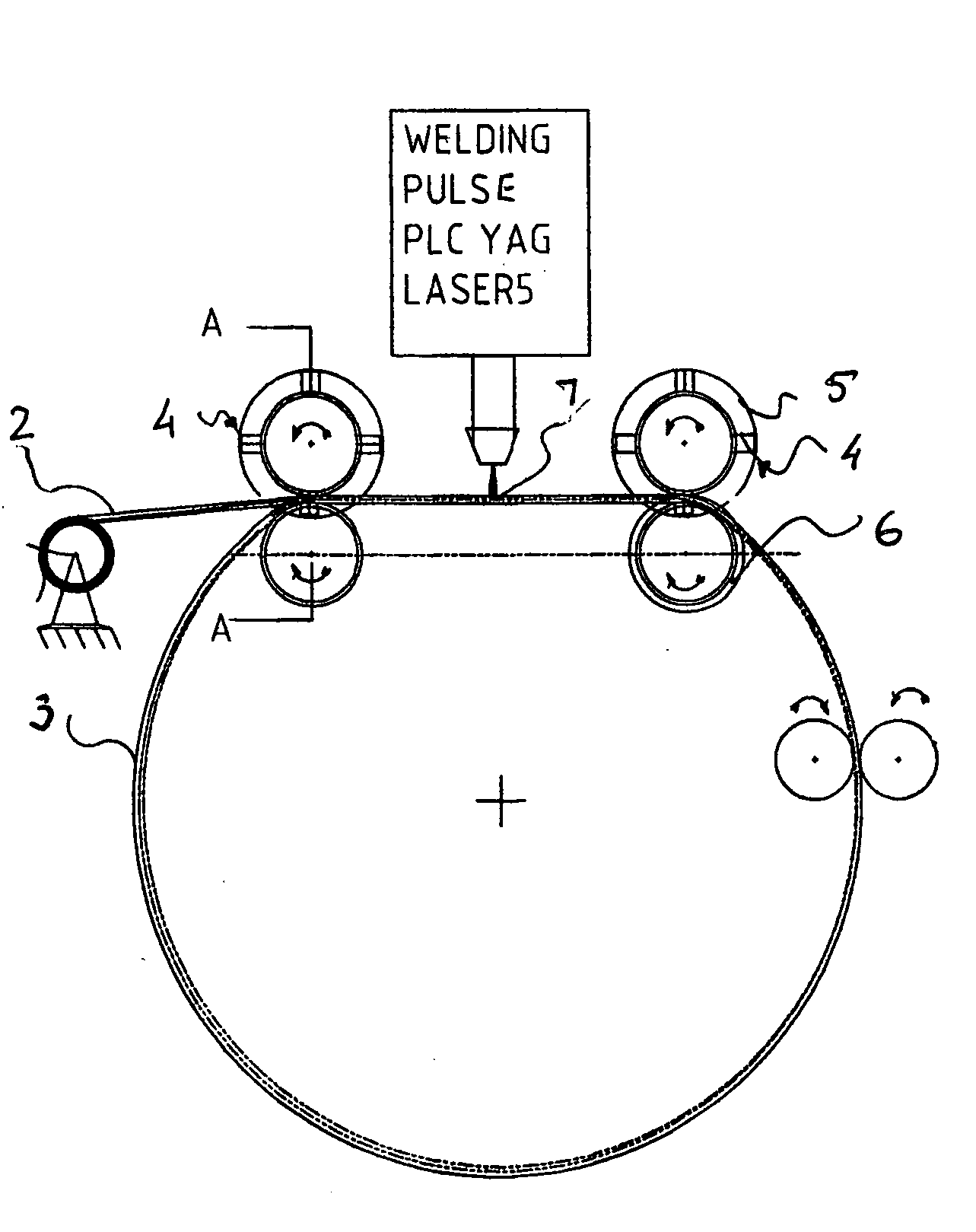

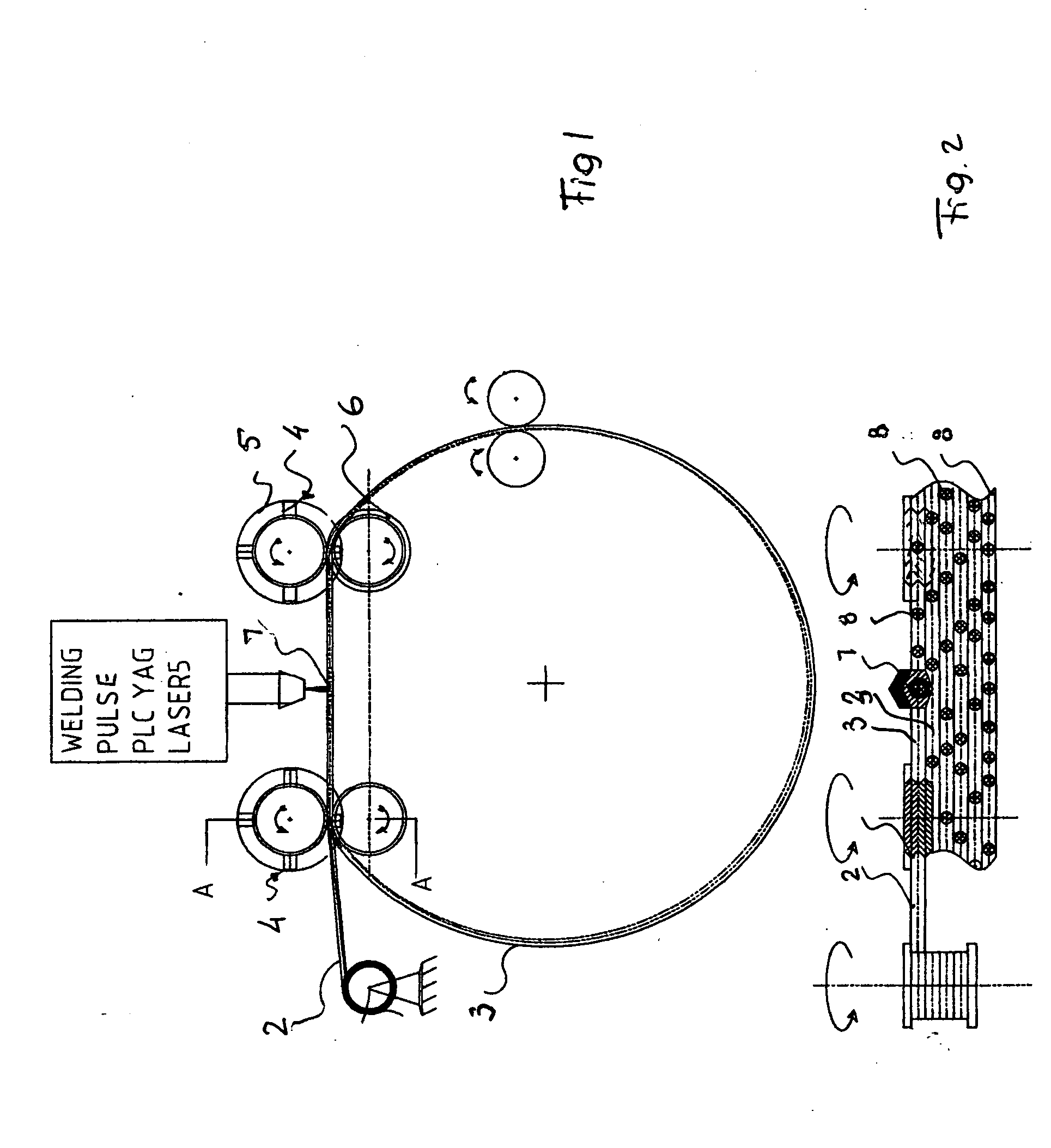

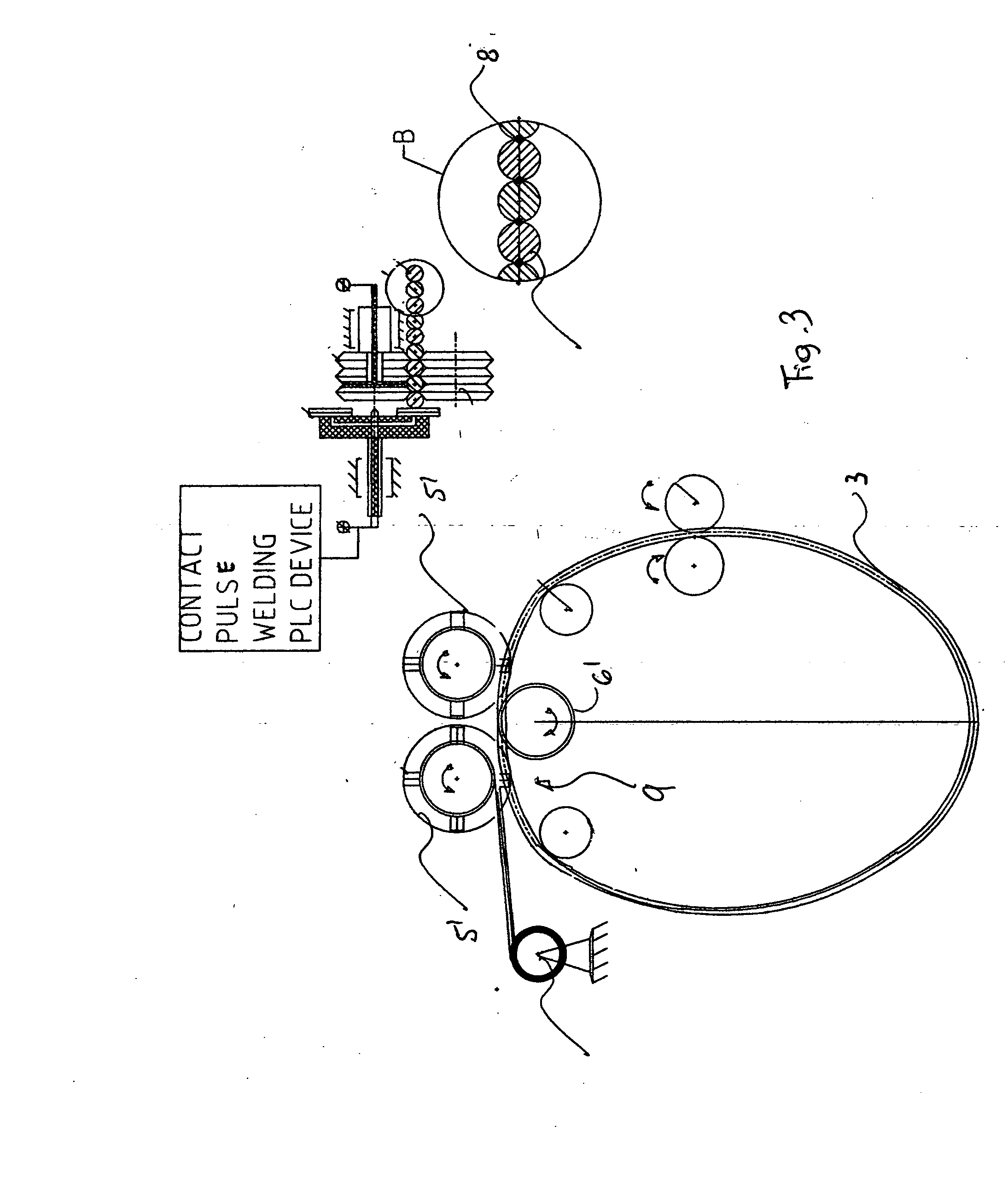

[0016]In accordance with the present invention a part which is identified as a whole with reference numeral 1 is produced from a wire, which is identified with reference numeral 2 and has a plurality of portions 3 that are formed during winding of the wire 2.

[0017]In an apparatus shown in FIG. 1 roller means are provided which are identified as a whole with reference numeral 4 and include upper rollers 5 and a lower rollers 6. The wire 2 is introduced between the rollers 5 and 6, and the rollers are driven in rotation by known means. During rotation of the rollers 5 and 6 the wire is wound forming a loop of a great diameter and so that subsequent portions of wire are arranged side-by-side with one another, preferably so as to be laterally in contact with one another.

[0018]The portions 3 of the wire 2 are then connected with one another by connecting means identified with reference numeral 7. The connecting means 7 can be of any type, for example welding means, glueing means, staplin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| strength | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com