Ultrasonic transducer with piezoelectric element and distance sensor

A technology of ultrasonic transducers and piezoelectric elements, applied in the direction of sensors, electrical components, sensor types, etc., can solve problems such as complex steps and affecting signal quality, and achieve the effect of low cost and reduced susceptibility to interference

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

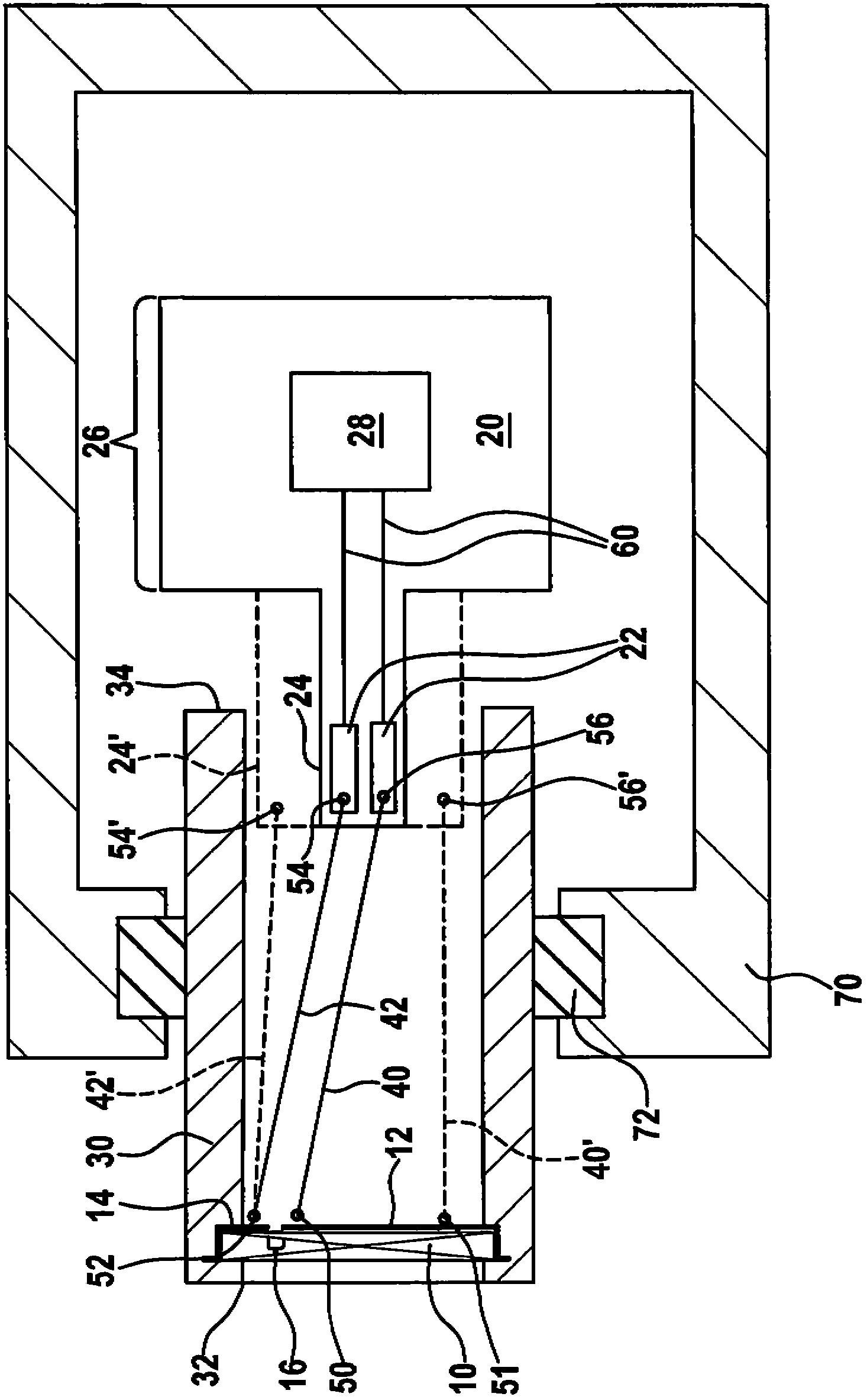

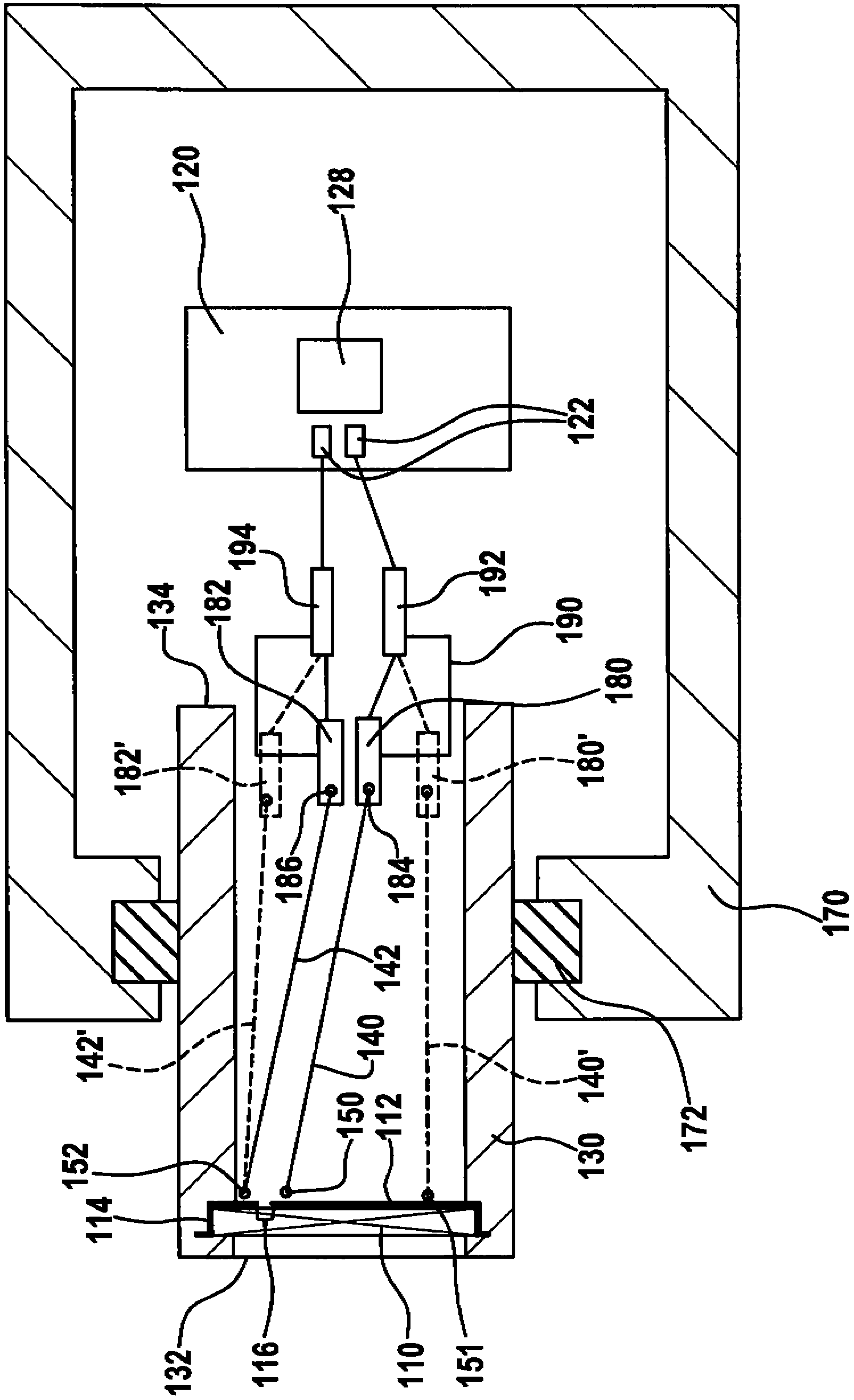

[0027] figure 1 An ultrasonic transducer according to the invention is shown with a piezoelectric element 10 , a printed circuit board 20 and a diaphragm disk 30 . The piezoelectric element 10 is bonded to the front end side 32 of the film disk 30 , preferably by means of a film, which forms a unit after bonding with the piezoelectric element 10 . The printed circuit board 20 carries two signal connections 22 , which are designed as planar conductors. The signal connection point 22 is arranged on a section 24 of the printed circuit board 22 protruding into the membrane tray 30 . Section 24 is designed as a protrusion of printed circuit board 20 . The piezoelectric element 10 is connected to the signal connection 22 via two lines 40 , 42 .

[0028] The piezoelectric element 10 comprises electrode surfaces 12 , 14 , between which an electrode gap with an electrode gap width 16 is formed. On the different electrode surfaces 12 , 14 of the piezo element 10 are formed contact p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com