High-speed sheet feeding without grip pliers

A plate-shaped, flat-plate technology, applied in the field of feeding devices, can solve problems such as increasing safety, and achieve the effects of eliminating unevenness, improving susceptibility to interference, and reducing time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

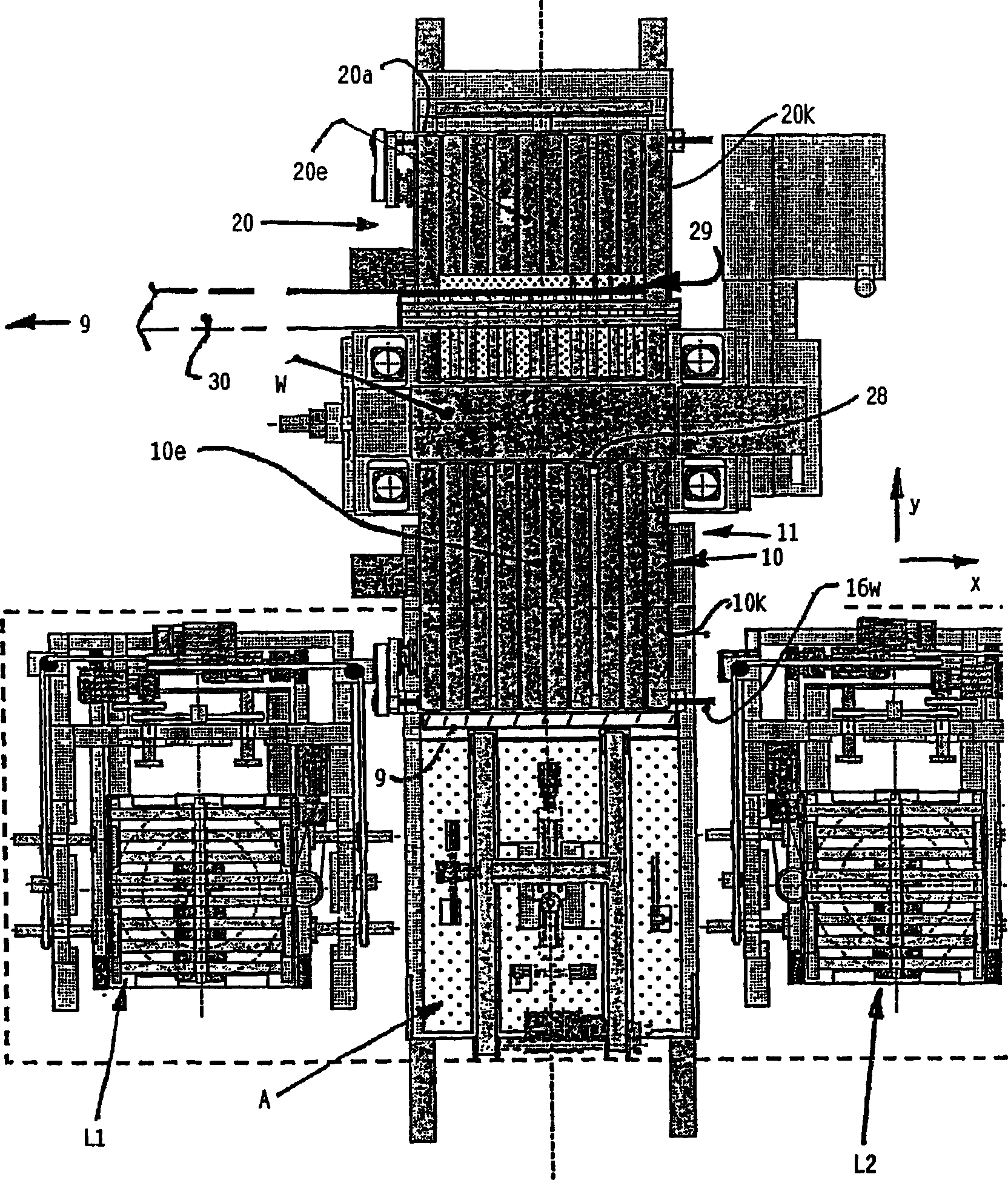

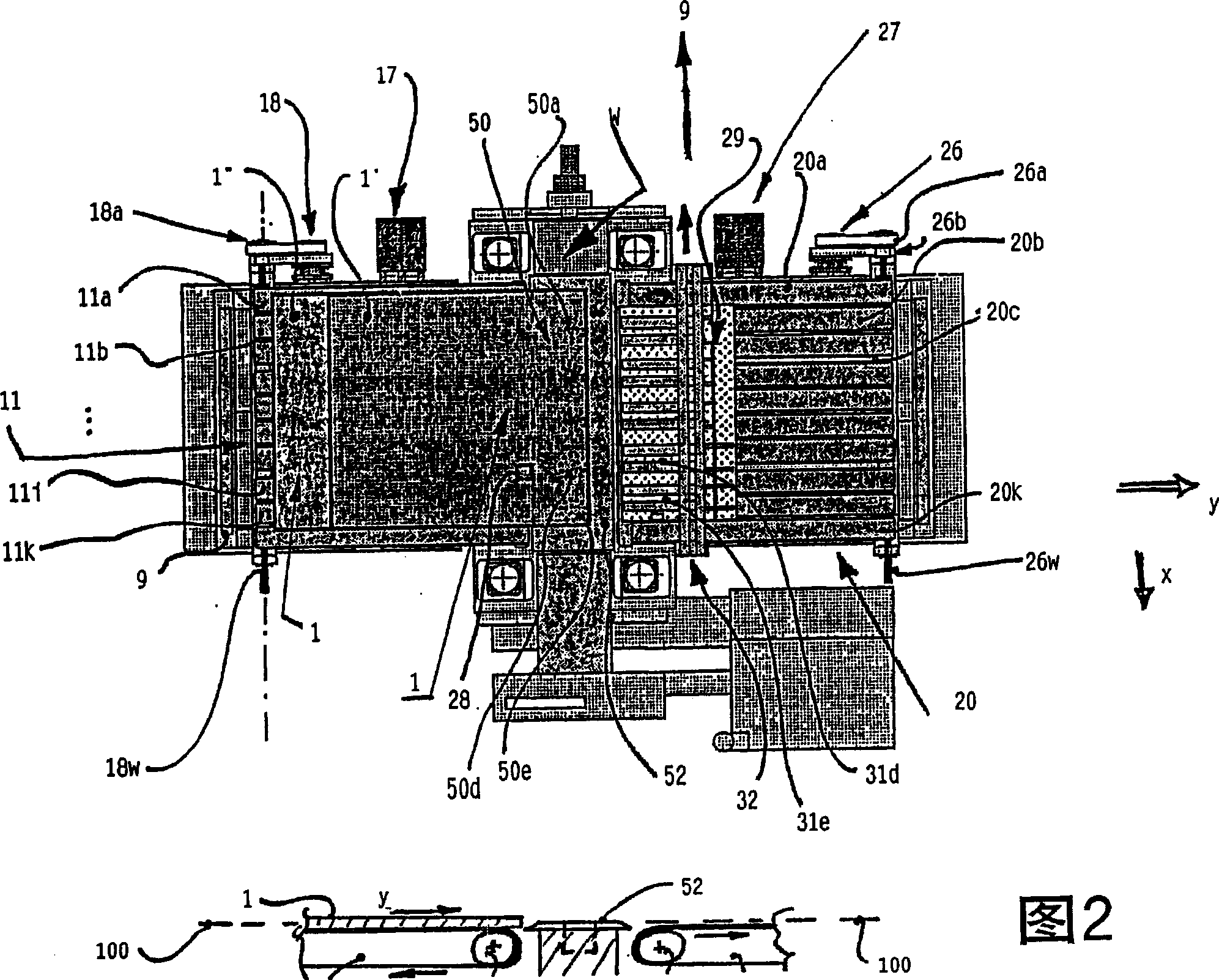

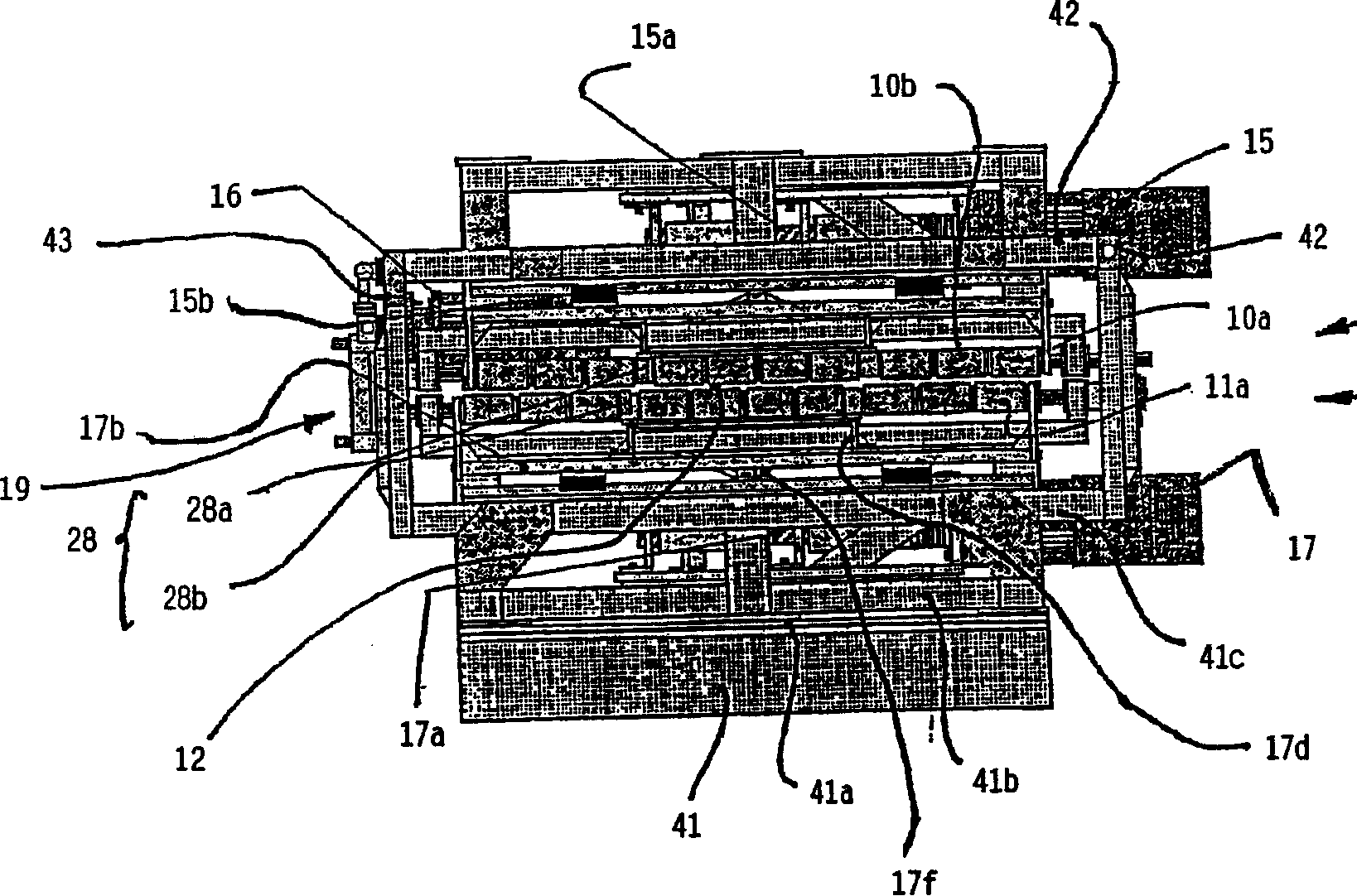

[0046] according to figure 1 The first embodiment represents the assembled state of the parts used. An upper feed device 10 and a similar lower feed device 11 (not visible) each consist of a plurality of parallel endless belts, in this example 10 belts 10 a to 10 k arranged next to one another. The middle band 10e is symbolically marked. The conveying device is oriented on a working area W, which in this example is formed by a transversely extending punching device 50 . Behind the tool there is a feeding device 20 which is designed similarly to the feeding device 10 . Its internal conveyor is partially covered by a discharge system 29 . In this example, too, ten conveyor belts are arranged closely next to each other as circulation systems, denoted by 20a to 20k. Also shown here is a symbolic conveyor belt 20e, which is a continuation of the input conveyor belt 10e.

[0047] The input conveyors 10 , 11 as first plate infeed and the outfeed conveyor 20 as second plate infee...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com