Steel roll transferring trolley in automatic steering

An automatic steering and transfer vehicle technology, which is applied in the direction of transportation and packaging, conveyor objects, conveyors, etc., can solve the problems of high cost, high energy consumption of forklifts, and large environmental pollution, and achieve the effect of preventing deflection and fast transfer

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

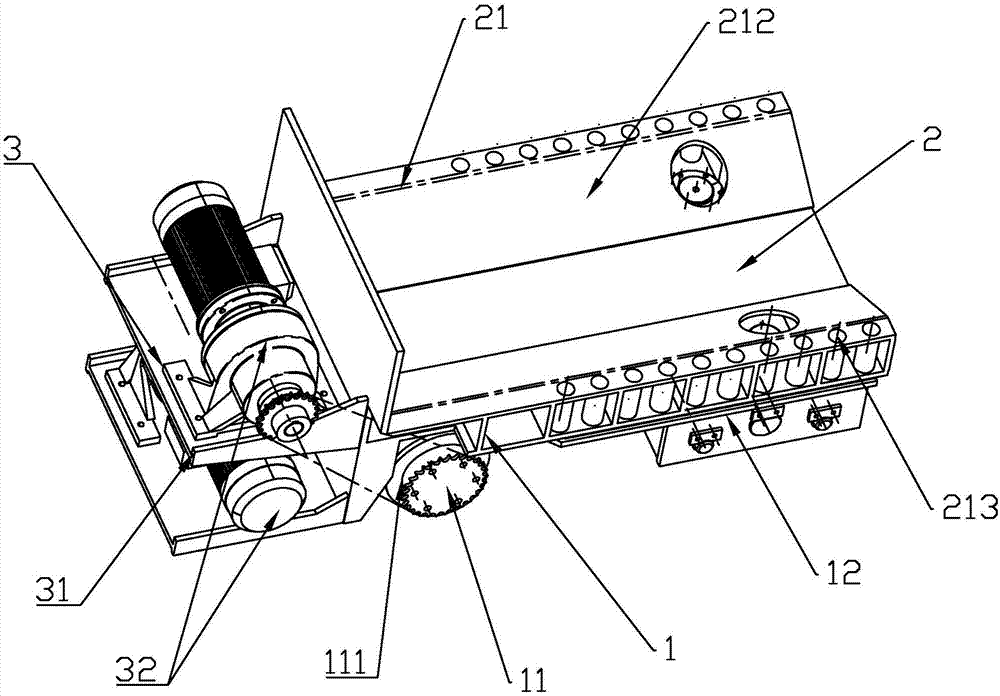

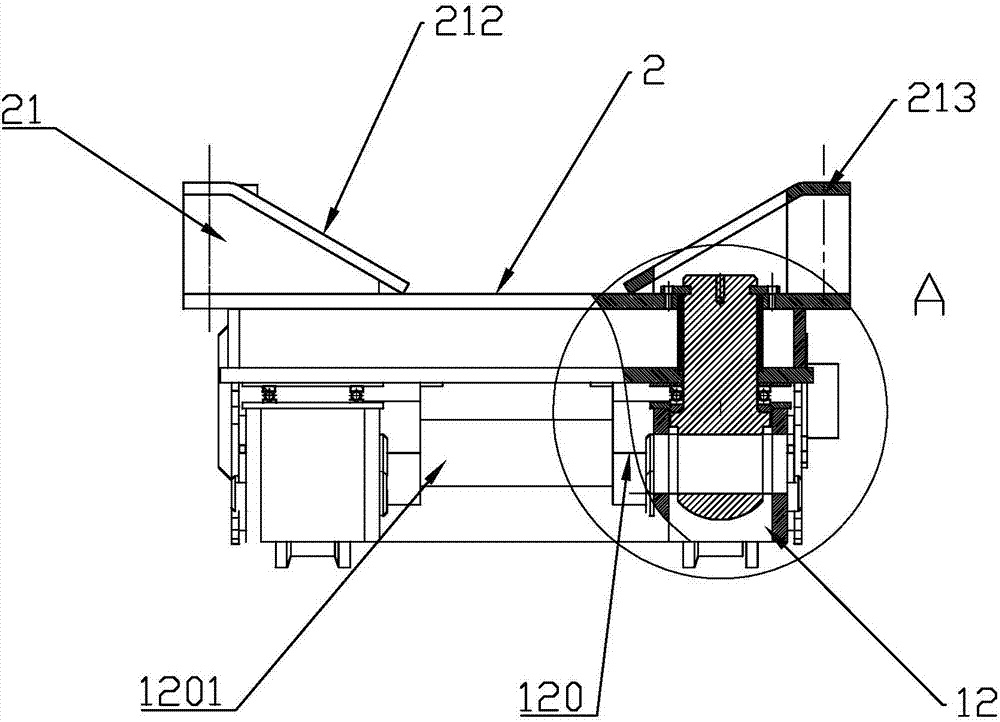

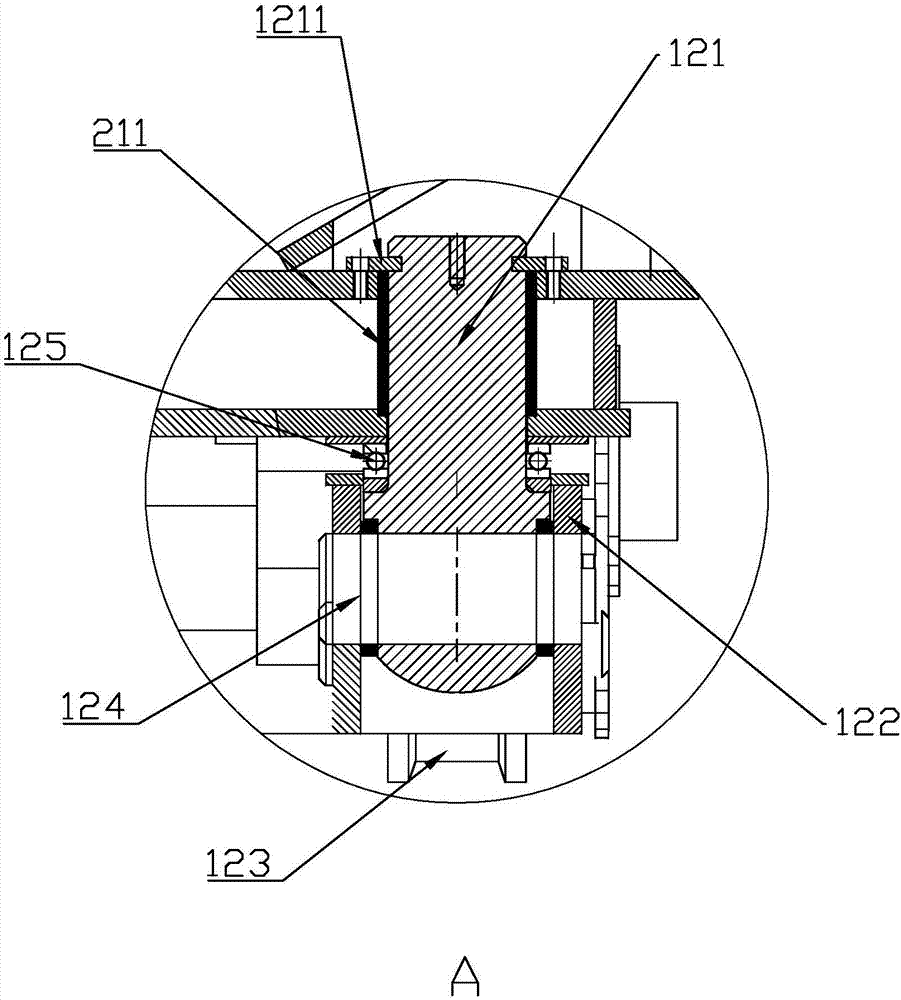

[0015] refer to Figure 1 to Figure 3 As shown, a steel coil transfer car with automatic steering in this embodiment includes a vehicle frame 1, a support plate 2 is arranged on the vehicle frame 1, and wing plates 21 for preventing the deflection of steel coils are installed on both sides of the support plate 2, One end of the vehicle frame 1 is equipped with a driving wheel frame 11, and the driving wheel frame 11 is connected to the electric device 3. The other end of the vehicle frame 1 is respectively equipped with two driven wheel groups 12, and the wing plates 21 on both sides are respectively provided with mounting holes 211 downwards. The driven wheel set 12 is penetrated and installed in the hole 211, and the driven wheel set 12 includes a top post 121 cooperating with the mounting hole 211, a stand 122 fixed on the lower end of the top post 121 and a wheel 123 installed in the middle of the stand 122. 123 is penetrated and fixed on the stand 122 through the axle 124...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com