Tooling device for tensioning steel anchor box inhaul cable and tensioning method thereof

A steel anchor box and tensioning technology, which is applied in the direction of erecting/assembling bridges, bridges, buildings, etc., can solve the problems of unsuitable tensioning tools and inability to stretch, etc., and achieve the effect of simple structure and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

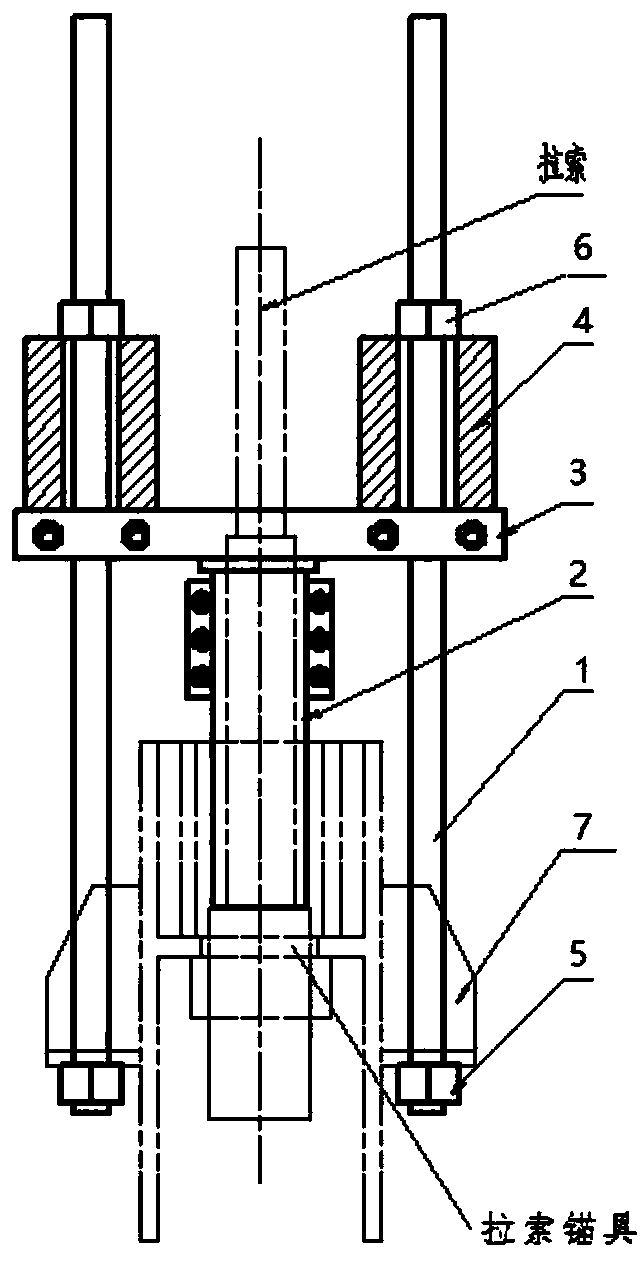

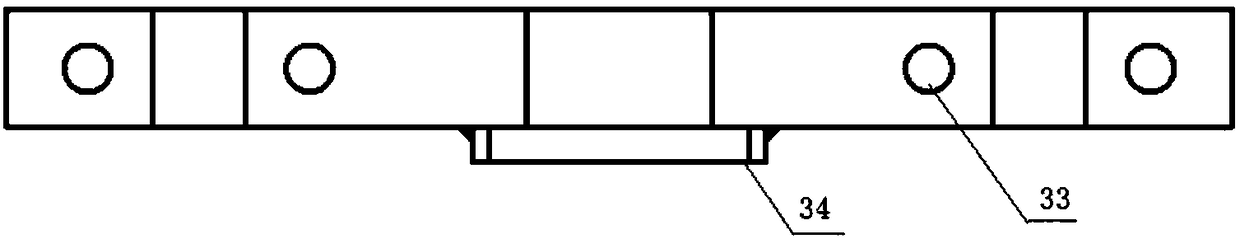

[0032] A method for tensioning steel anchor box cables, comprising the following steps:

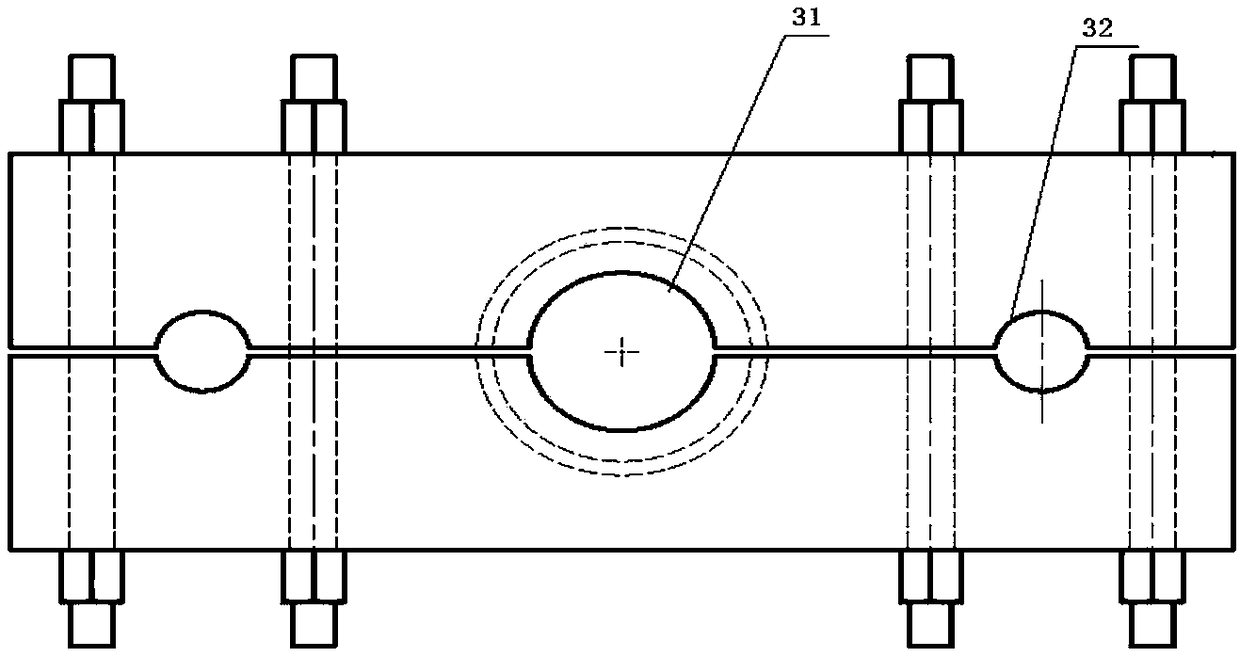

[0033] A: Install the tensioning tube: the convex stop 21 at the upper end of the tensioning tube 2 is connected with the concave stop 34 of the slot hole 31 of the shoulder beam 3 or the convex stop 23 at the upper end of the tensioning tube 2 is connected with the groove of the shoulder beam 3 The notch 35 of the hole 31 is connected, and then the fork ear 22 of the tensioning cylinder 2 is connected by bolts, so that the tensioning cylinder 2 forms a whole;

[0034] B: Install the pole beam: Install the pole beam 3 at the upper end of the tensioning cylinder 2; when installing, put the slot hole 31 of the pole beam 3 on the cable, fix the pole beam 3 by bolts, and the tension rod 1 is connected from the pole beam 3 The circular hole 32 passes through;

[0035] C: Install the tension rod: first pass the tension rod 1 through the round hole 31 of the pole beam and then pass through the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com