Perforating method for perforating one row of holes in hose

A single row of holes and hose technology, applied in metal processing and other directions, can solve the problems of unsatisfactory quality, difficulty in forming a single row of holes, difficult to control the hole diameter, etc., to ensure roundness, simple structure, and good drilling quality Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The principles and features of the present invention are described below in conjunction with the accompanying drawings, and the examples given are only used to explain the present invention, and are not intended to limit the scope of the present invention.

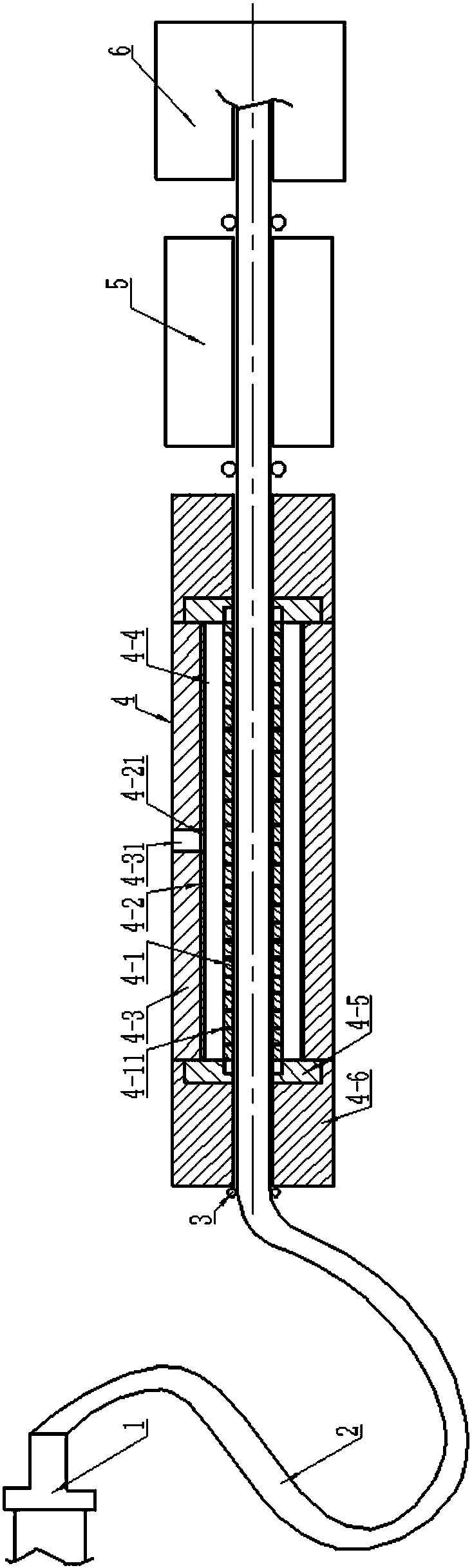

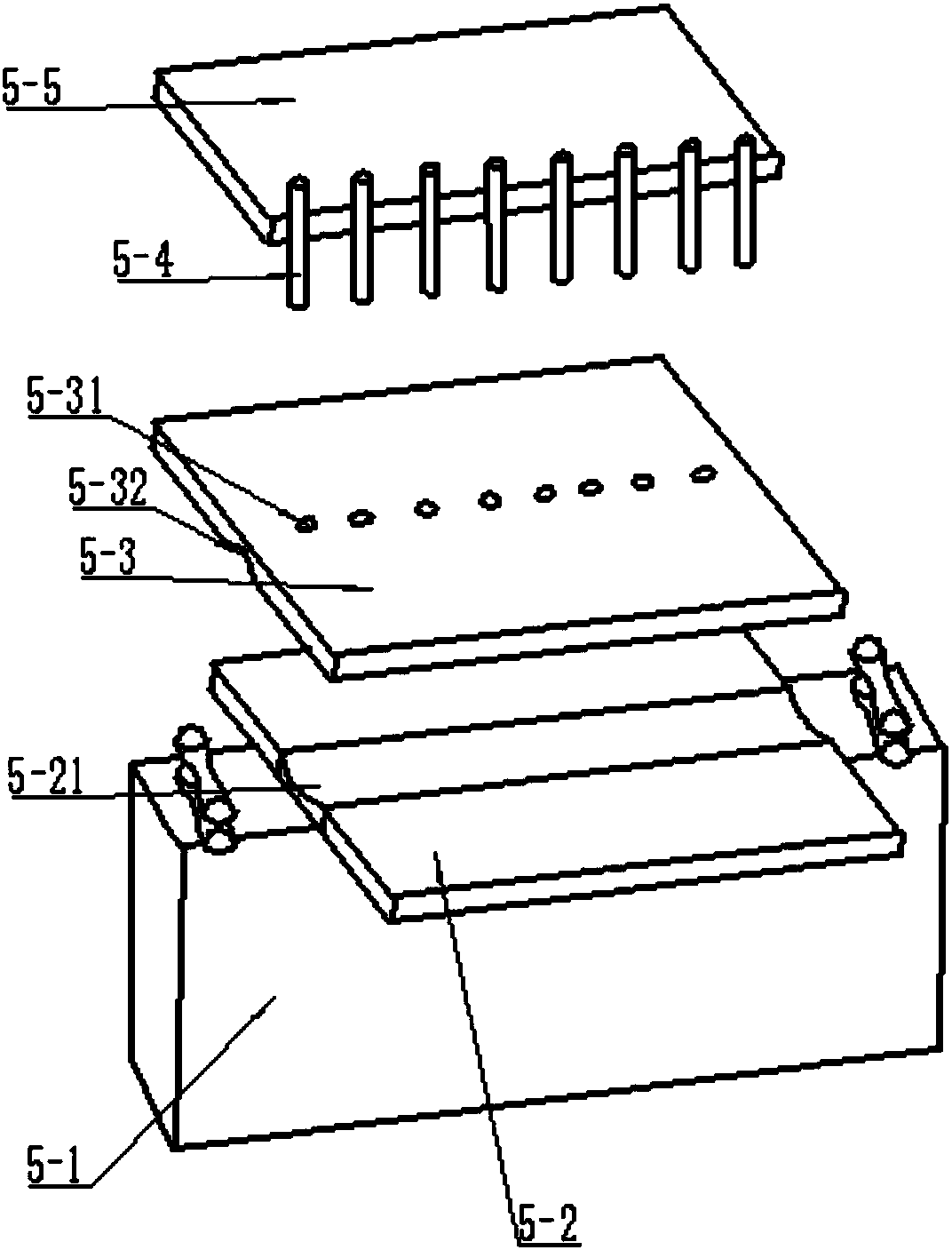

[0037] Such as Figure 1-Figure 5 Shown, a kind of perforation method of hose perforation single row, comprises the following steps:

[0038] Step 1. Take a pre-punched hose 2 with a diameter of 6-25mm; connect one end of the pre-punched hose 2 to the faucet 1. After it is filled with water, seal the soft hose with a plug The plugging of both ends of the tube 2;

[0039] Step 2, put the water-filled hose 2 into the liquid nitrogen cooling device 4 under the action of the tractor for cooling until the water in the hose 2 freezes into ice;

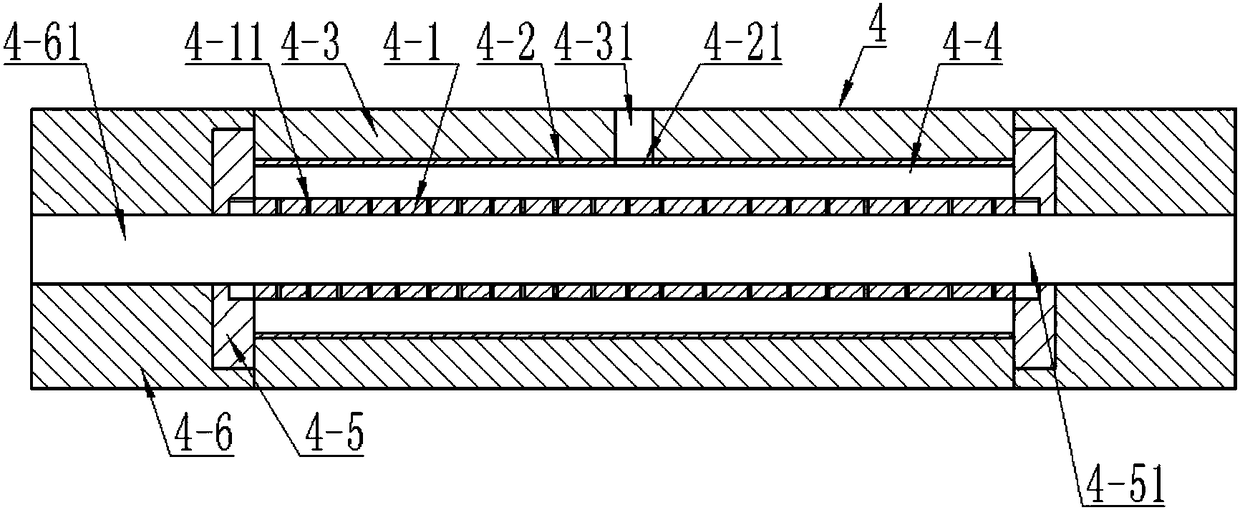

[0040] The liquid nitrogen cooling device 4 includes an inner cylinder 4-1 and an outer cylinder 4-2, and the outer cylinder 4-2 is sleeved on the outer circumference of the inn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com