Titanium alloy box-shaped part hot drawing method

A technology for titanium alloys and parts, applied in other household appliances, household appliances, applications, etc., can solve the problems of hot drawing and forming of parts, and achieve the effect of convenient operation and use, simple tooling structure, and reduction of batch production costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] In order to make the purpose, content, and advantages of the present invention clearer, the specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

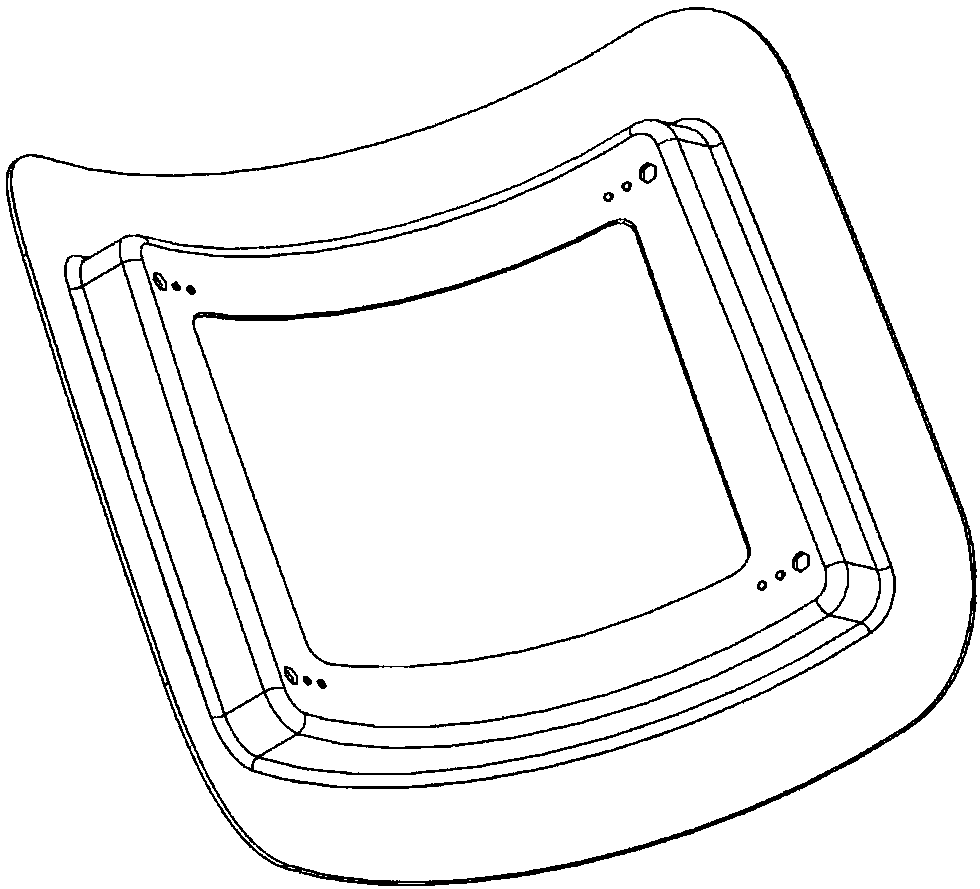

[0033] Such as figure 1 As shown, the formed TA15 titanium alloy part is formed. The shape of the part is a hyperboloid surface that fits the aircraft cabin. It requires high precision, and there is a large area of deep depression on the hyperboloid surface. Parts are difficult to form, unreasonable mold design or improper process is easy to form wrinkles on the surface, and the vertical wall and rounded corners of box-shaped parts are easy to crack.

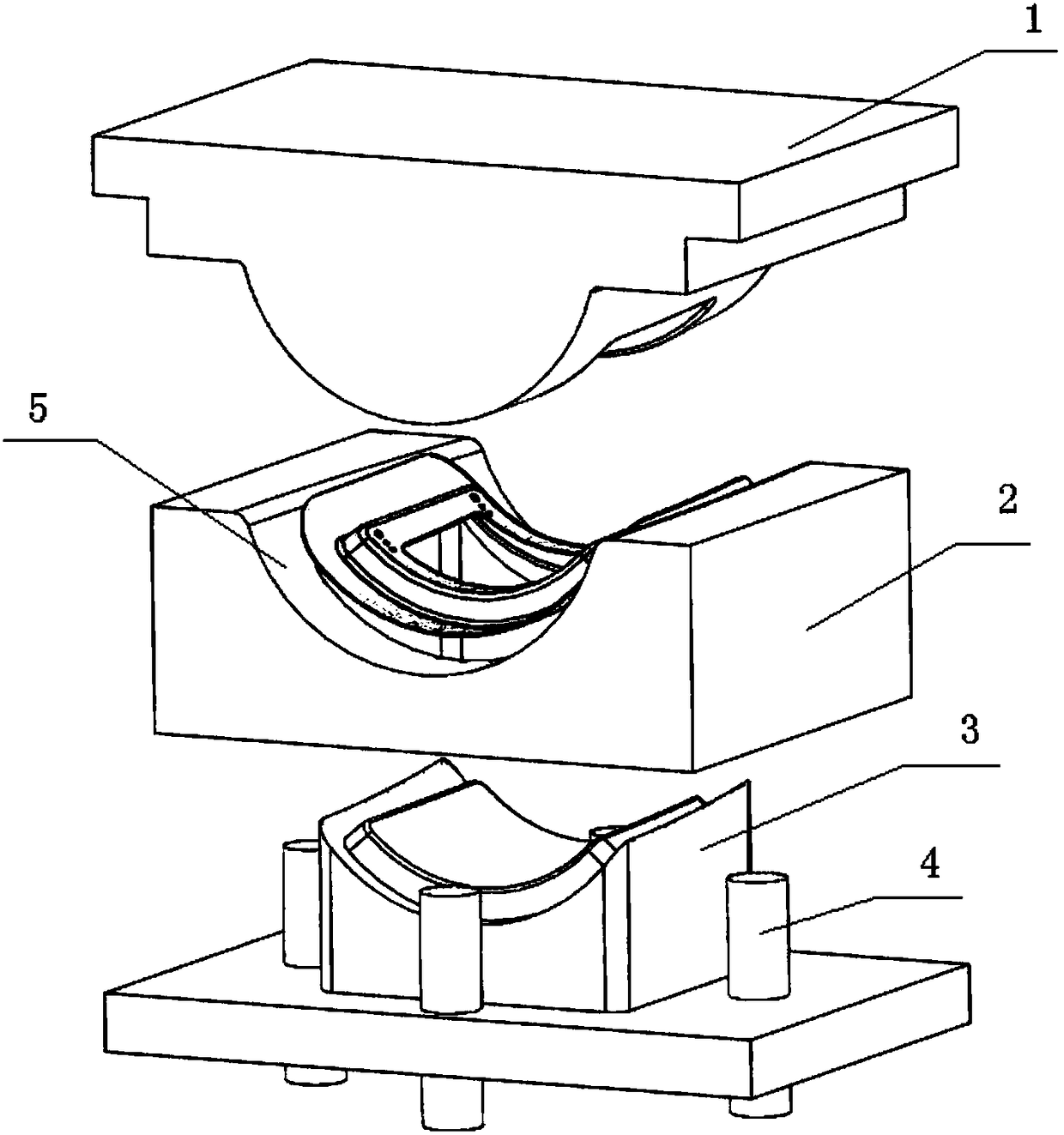

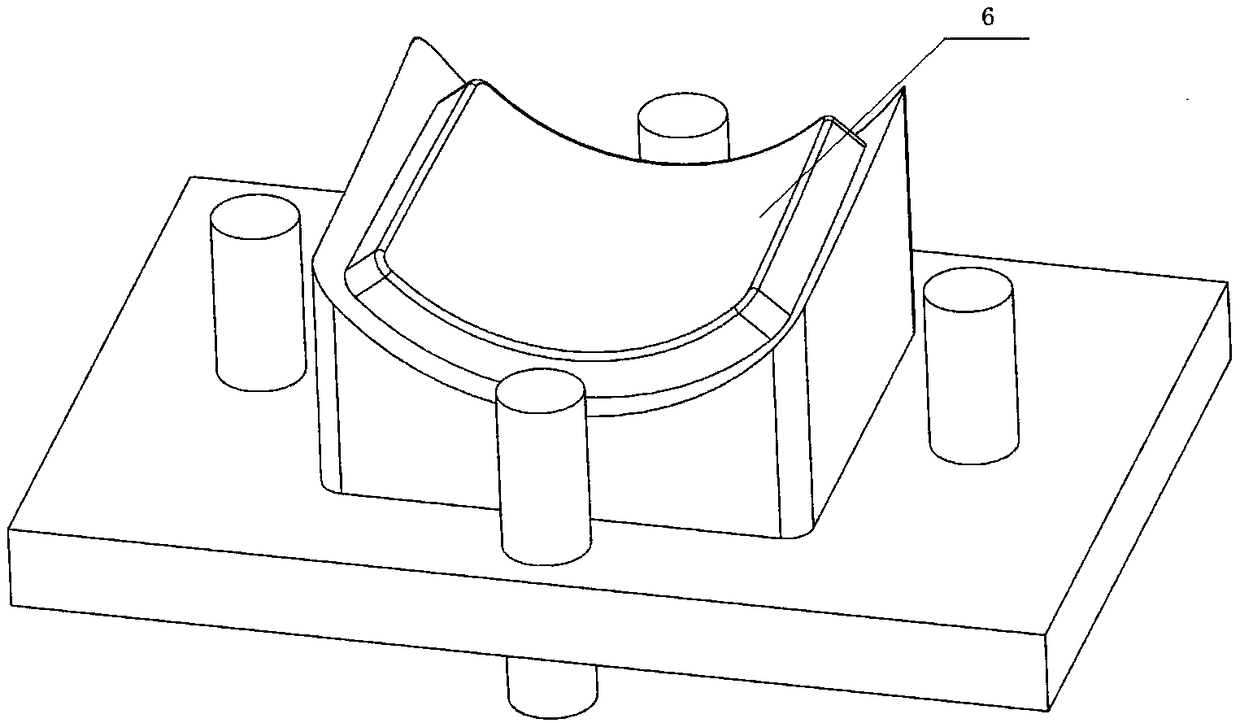

[0034] Such as Figure 2 to Figure 4 As shown, a device provided by the present invention to realize the forming of the titanium alloy part TA15 with complex profiles includes an upper mold 1, a middle mold 2 and a lower mold 3, and the upper mold 1, the middle mold 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com