Large-caliber optical part elastic chucking tool and method for numerical-control grinding and polishing

A technology of optical parts and large diameter, which is applied in the direction of grinding/polishing equipment, grinding workpiece support, optical surface grinder, etc., to achieve the effect of convenient operation, solving technical bottlenecks and reducing labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] In order to make the purpose, content and advantages of the present invention clearer, the specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

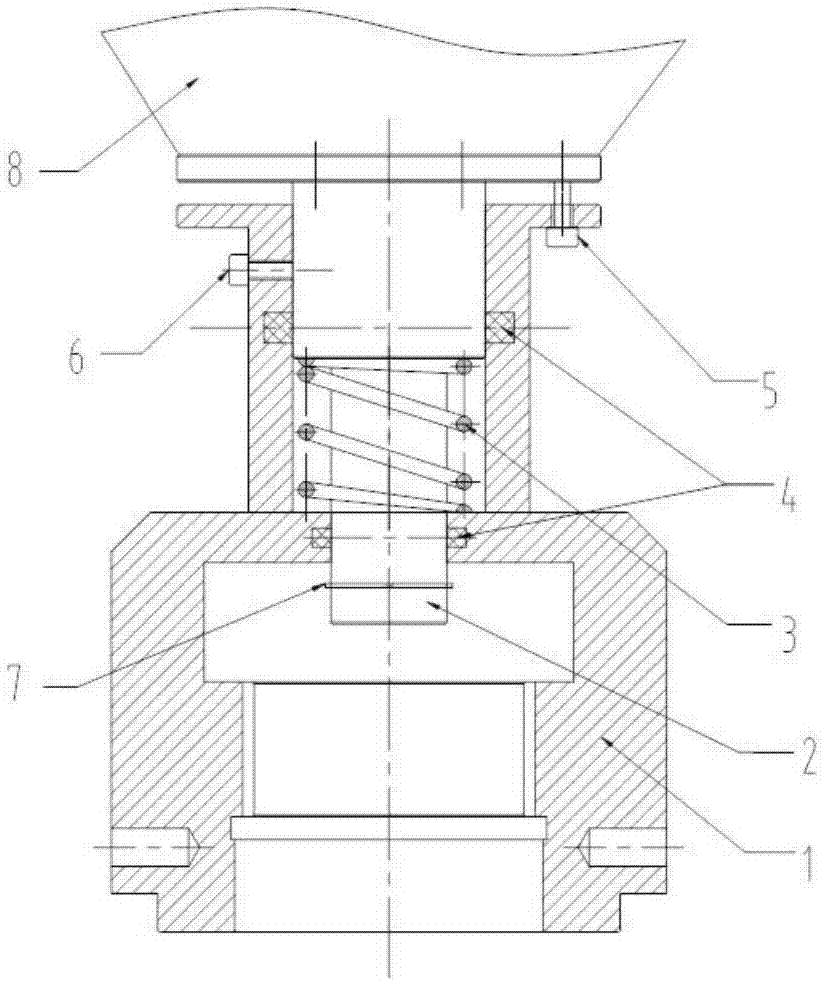

[0033] This embodiment proposes a large-diameter optical parts elastic clamping tool for CNC grinding and polishing. The general assembly structure of the tool is as follows figure 1 shown. The tooling includes a base 1 , a fixture fixing device 2 , a spring 3 , a sealing ring 4 , a booster screw 5 , a limit screw 6 , a buckle 7 and a fixture 8 .

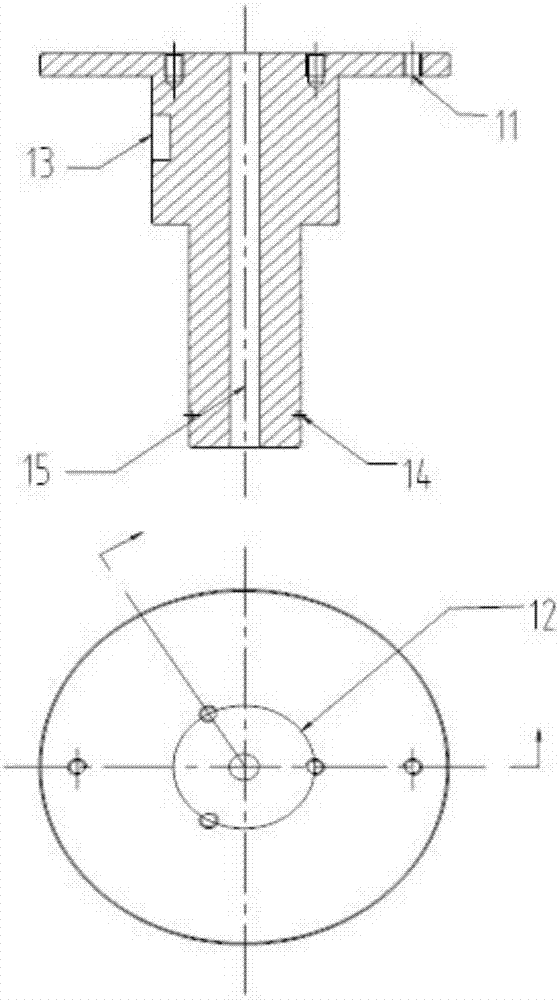

[0034] Clamp fixing device 1, its structure is as figure 2 As shown, for fixing the fixture, the material can be selected from aluminum, aluminum alloy, iron, iron alloy, etc., and in this embodiment it is aluminum alloy. The jig fixture 1 includes a flange platform and a mandrel. Wherein, the flange platform is composed of a flange 12 and a threaded through hole 11 at an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com