Method for manufacturing titanium alloy straightener blade

A rectifying blade and manufacturing method technology, applied in the field of rectifying blade preparation, can solve the problems of complex tooling structure, high equipment requirements, low yield rate, etc., and achieve the effect of simple tooling structure, smooth appearance surface, and high qualified rate of finished products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

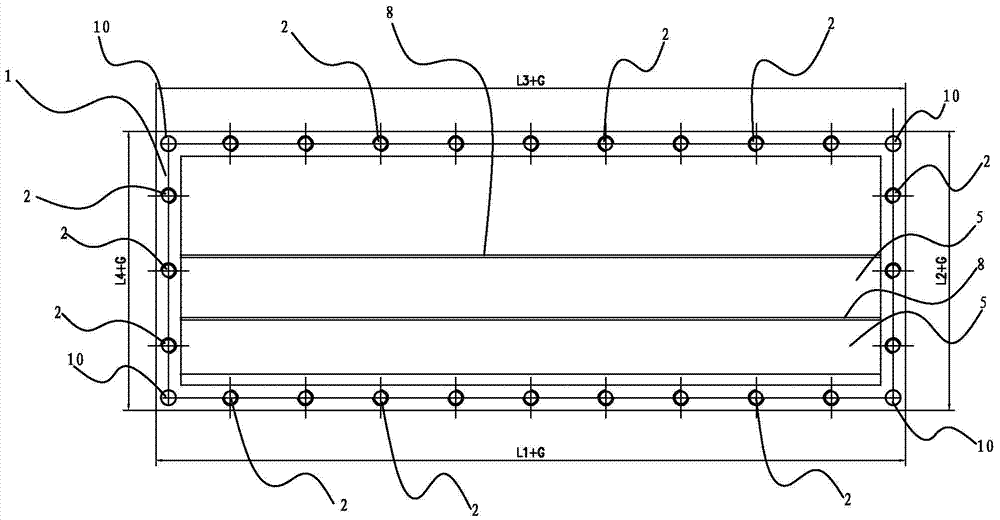

[0053] A. Preparation of blank 1: Carry out water cutting of the sheet after hot rolling into blank 1, and use one side of blank 1 as a reference to mill blank 1 according to the size of blank 1; the function of this step is to cut the sheet into Blank 1 of suitable size is convenient for subsequent processing to meet the required size of the product, L1=300mm, L2=100mm, L3=300mm, L4=100mm, H=30mm, and the machining allowance G is 20mm;

[0054] B. Machining screw holes 2 around: machine screw holes 2 around the center of the margin, process 5 M10 screw holes on L1 and L3 sides, and process 3 M10 screw holes on L2 and L4 sides; M10 is the processed one The size of the screw hole, in mm.

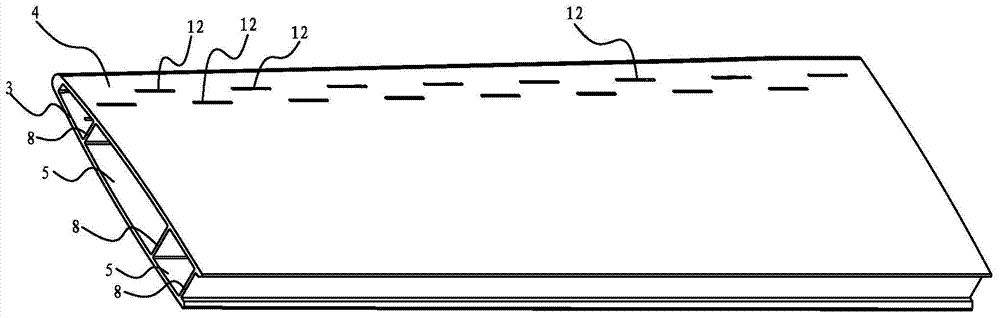

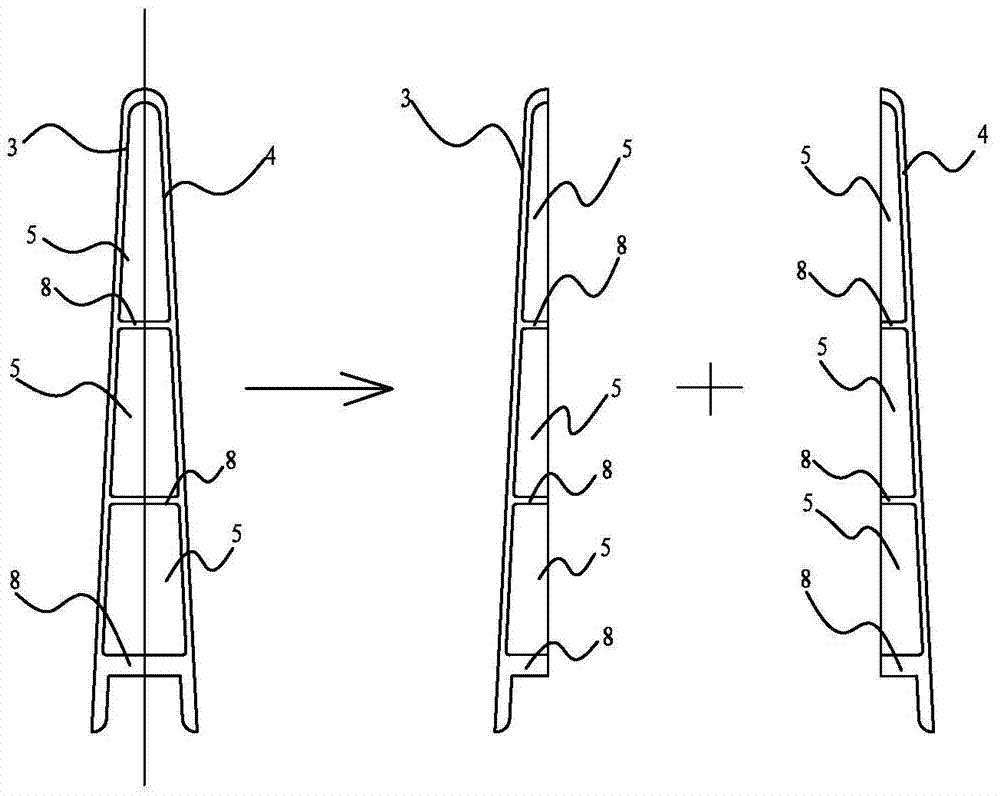

[0055] C. Milling the first datum plane: the left part 3 and the right part 4 of step B are detachably fixed on the tooling base 6 through the surrounding tension screws 7 respectively, and the upper surface of the left part 3 or the right part 4 is milled first Datum;

[0056] D. Process t...

Embodiment 2

[0074] Except for the diffusion bonding process, other steps are the same as in Embodiment 1. The difference is that in the G step diffusion connection process: the diffusion connection parameters are as follows:

[0075] 1. Close the door and vacuumize to 9×10 -3 Pa, start heating;

[0076] 2. It takes 30 minutes for the temperature to rise from 0°C to 350°C;

[0077] 3. Keep warm at 350°C and vacuumize to 4×10 -3 Pa, continue heating;

[0078] 4. It takes 30 minutes for the temperature to rise from 350°C to 600°C;

[0079] 5. Keep warm at 600℃ to 4×10 -3 Start heating after Pa;

[0080] 6. It takes 40 minutes for the temperature to rise from 600°C to 950°C;

[0081] 7. At 950°C, keep warm for 240 minutes; when the temperature reaches 950°C, the pressure increases to 12MPa;

[0082] 8. Turn off the heating power supply to stop heating, turn off the hydraulic station to stop pressurization, cool down to below 180°C and start the furnace.

[0083] Connection results: F...

Embodiment 3

[0085] Except for the diffusion bonding process, other steps are the same as in Embodiment 1. The difference is that in the diffusion connection process of step G: the diffusion connection parameters are as follows: 1. Close the machine door and evacuate to 9×10 -3 Pa, start heating;

[0086] 2. It takes 30 minutes for the temperature to rise from 0°C to 350°C;

[0087] 3. Keep warm at 350°C and vacuumize to 4×10 -3 Pa, continue heating;

[0088] 4. It takes 30 minutes for the temperature to rise from 350°C to 600°C;

[0089] 5. Keep warm at 600℃ to 4×10 -3 Start heating after Pa;

[0090] 6. It takes 30 minutes for the temperature to rise from 600°C to 920°C;

[0091] 7. At 920°C, keep warm for 180 minutes; when the temperature reaches 920°C, the pressure increases to 12MPa

[0092] 8. Turn off the heating power supply to stop heating, turn off the hydraulic station to stop pressurization, cool down to below 180°C and start the furnace.

[0093] Connection results: Fo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com