Wind driven generator stator iron core lamination forming tool and a lamination forming method

A technology for wind turbines and stator iron cores, which is applied in the direction of manufacturing stator/rotor bodies, etc., can solve the problems of poor alignment of positioning ribs embedded in grooves, difficult separation of positioning support cylinders, etc., to achieve easy on-site operation and improve the quality of lamination welding. , the effect of reducing the probability of scratches

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

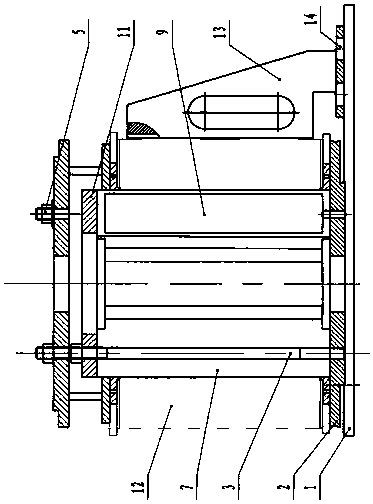

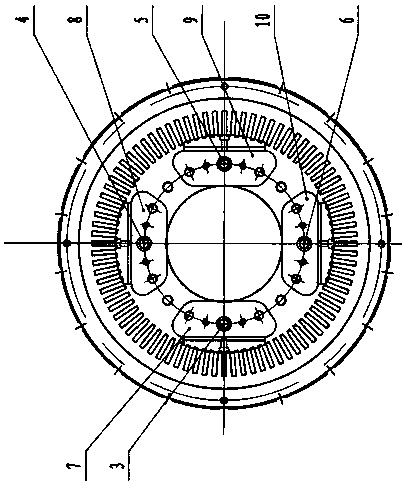

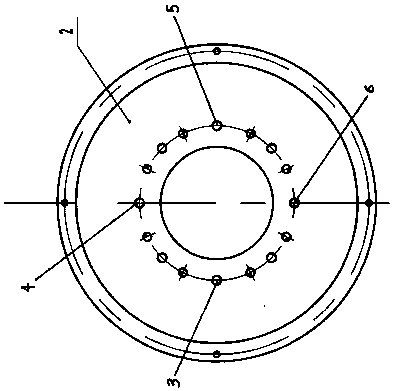

[0022] The present invention will be described in detail below in conjunction with the drawings:

[0023] A wind-power generator stator core laminated molding tooling, comprising a laminated molding operating platform 1 and a stator core silicon steel sheet 12. A stator core laminated base plate 2 is provided on the laminated molding operating platform 1, and the stator iron On the same circumference of the top surface of the core lamination base plate 2, a left positioning lamination screw 3, a rear positioning lamination screw 4, a right positioning lamination screw 5 and a front positioning lamination screw 6 are respectively arranged. The outer circle of 12 is provided with a reinforcing rib embedding groove 20, a left arc-shaped lamination positioning support plate 7 is passed through the left positioning lamination screw 3, and a rear arc lamination is passed through the rear positioning lamination screw 4 Press positioning support plate 8, on the right positioning laminati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com