Side-entering type backlight module and liquid crystal display device and backlight plate optical inspection method

An edge-type backlight and backlight plate technology, applied in the field of optical inspection of light guide plates, can solve the problems of touching and moving light guide plates, contamination of light guide plates, enterprise losses, etc., to reduce costs, facilitate transportation, and save costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0046] Embodiment 1 provides a side-entry backlight module, which includes a backlight panel main body, a light source, a light source moving module, and a shading module.

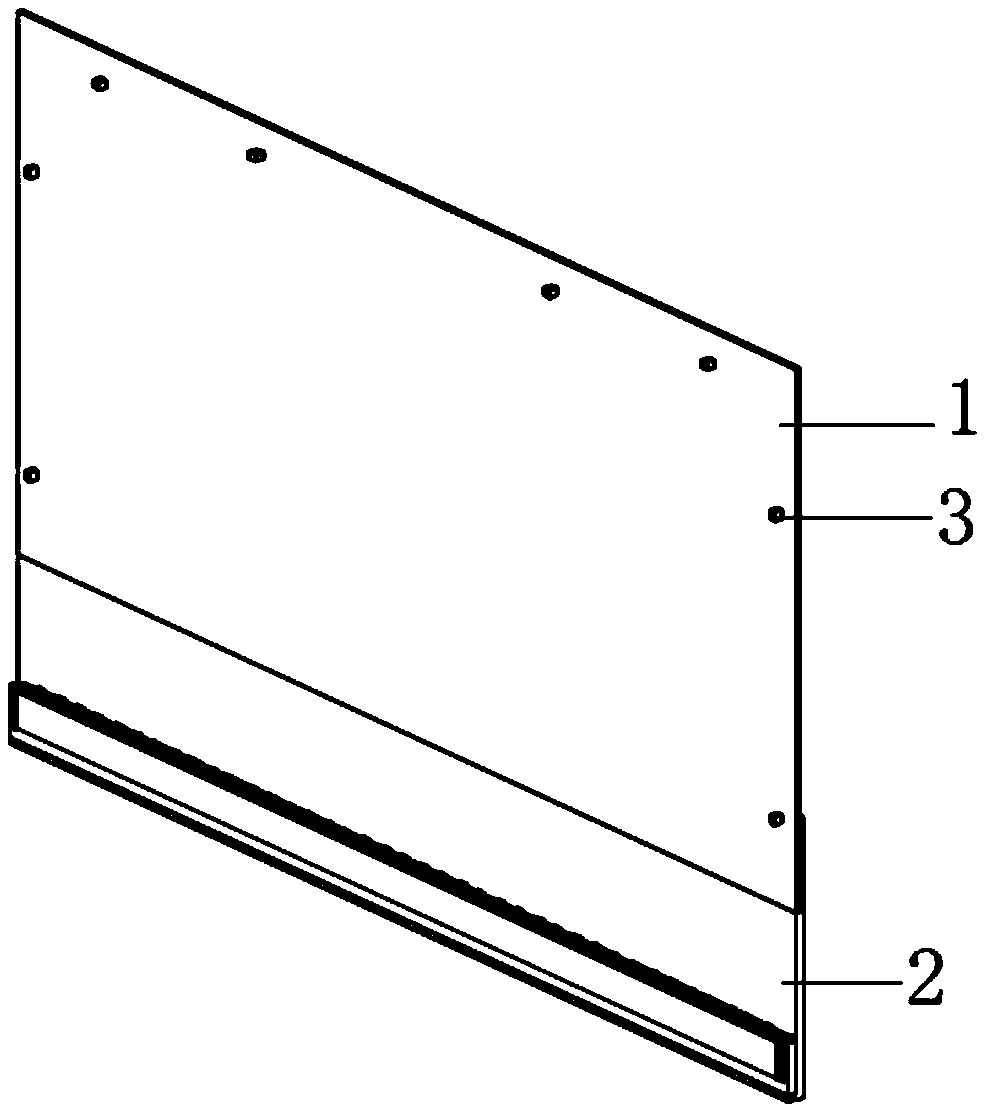

[0047] Please refer to the attachedfigure 1 The main body of the backlight panel includes a first substrate 1 and a second substrate 2 for fixing the light guide plate to be inspected, and the first substrate 1 and the second substrate 2 are detachably connected to form other components of the backlight module , such as the accommodation space for the light source, the light source moving module and the shading module; the first substrate 1 and the second substrate 2 connected in a detachable manner are not integral structures and can be placed separately during transportation for convenient transportation.

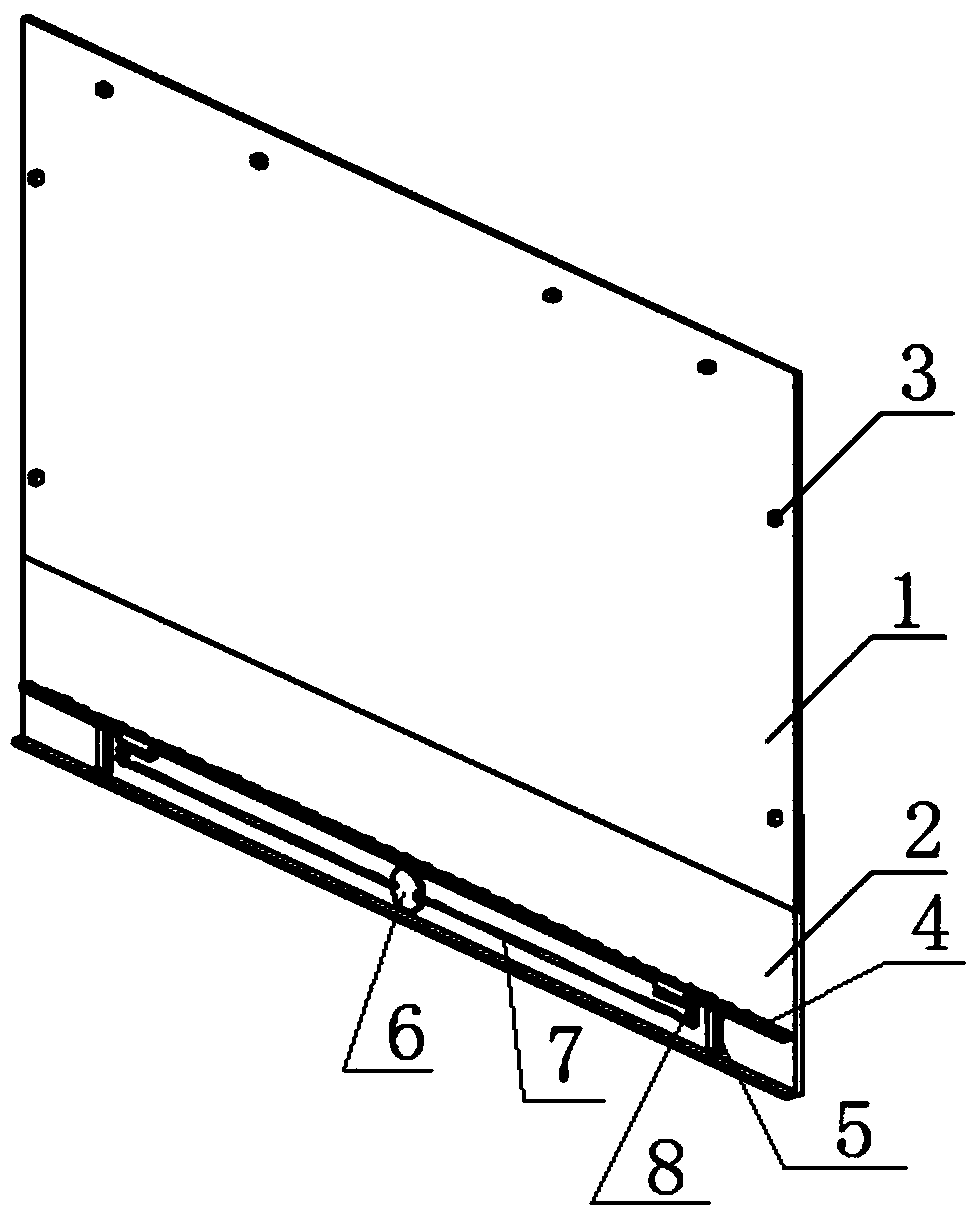

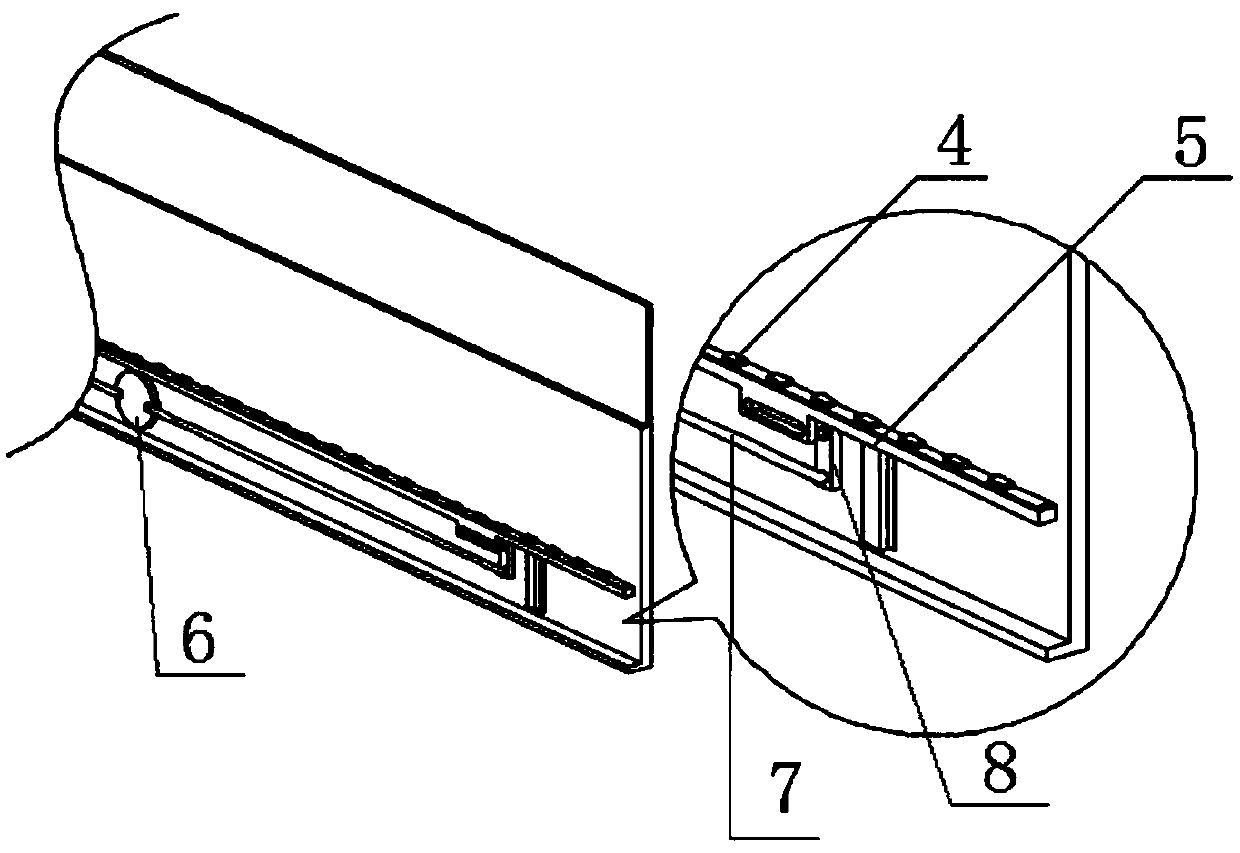

[0048] Please refer to attached figure 2 and image 3 , the light source moving module is arranged on the front side of the second substrate 2, the light source moving module includes a light source...

Embodiment 2

[0061] This embodiment provides a liquid crystal display device, which includes a light guide plate and the above-mentioned edge-type backlight module. The light guide plate is fixed on the first substrate 1 and is arranged opposite to the light source 4 .

[0062] Wherein, for the specific structure of the side-type backlight module of this embodiment, please refer to the relevant descriptions of the previous embodiments, and details are not repeated here.

[0063] It should be noted that, in this embodiment, the light guide plate is fixedly installed on the first substrate through a plurality of positioning pins 3. In this embodiment, a plurality of positioning pins 3 are used to fix the light guide plate on the first substrate. The positioning pins 1 Cooperate with the card slot of the light guide plate to ensure that the light guide plate will not shake on the first substrate.

Embodiment 3

[0065] This embodiment provides an optical inspection method for a light guide plate, which is implemented based on the above-mentioned side-entry backlight module, and the method includes the following steps:

[0066] S101, fixing and installing the light guide plate to be inspected on the first substrate through a plurality of positioning pins;

[0067] S102, turning the knob clockwise, the knob drives the turntable 6 to rotate;

[0068] S103, the turntable drives two L-shaped levers 8 to make a fan-shaped movement around the rotating shaft 10 through the two connecting rods 7;

[0069] S104, the projections 83 of the two L-shaped levers respectively fan-shaped swing, and at the same time jack up the light source support frame 5;

[0070] S105, the light source support frame 5 drives the light source 4 to move upward in a direction perpendicular to the light source support frame 5, so that the light source is close to the light incident side of the light guide plate;

[00...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com