Multi-pipe floating complex curved surface self-finding track electrolytic processing device and method

A processing device and complex curved surface technology, applied in the field of multi-tube floating complex curved surface self-tracking electrolytic processing device, can solve the problems of low processing efficiency, achieve the effects of easy operation, shortened preparation time, and improved processing stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

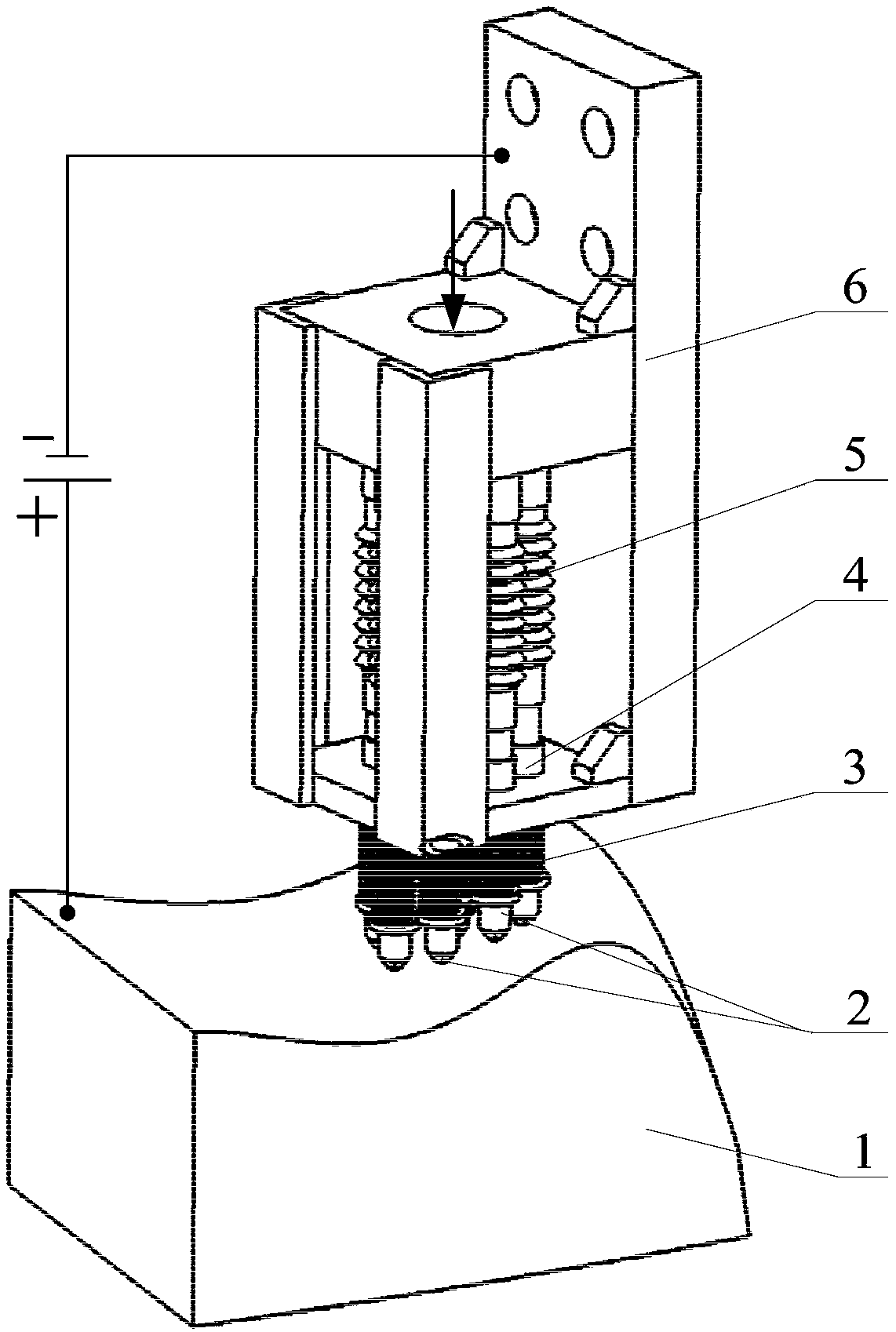

[0020] figure 1 In the schematic diagram of self-tracking electrolytic machining of multi-tube floating complex curved surfaces shown, first, the control device of the numerical control system moves to the designated position on the surface of the workpiece to ensure that the porous nylon ball 9 at the bottom of the group tube electrode 2 contacts the surface of the workpiece 1 to be processed, and gives a certain pressure. Then, turn on the pressure pump and adjust the hydraulic pressure parameters; finally, set the processing curve and processing parameters in the control system, and turn on the power to start processing. During the processing, each tube electrode 2 will move up and down along with the ups and downs of the surface contour of the workpiece 1, and finally process the contour of the curved surface consistent with the shape of the blank workpiece.

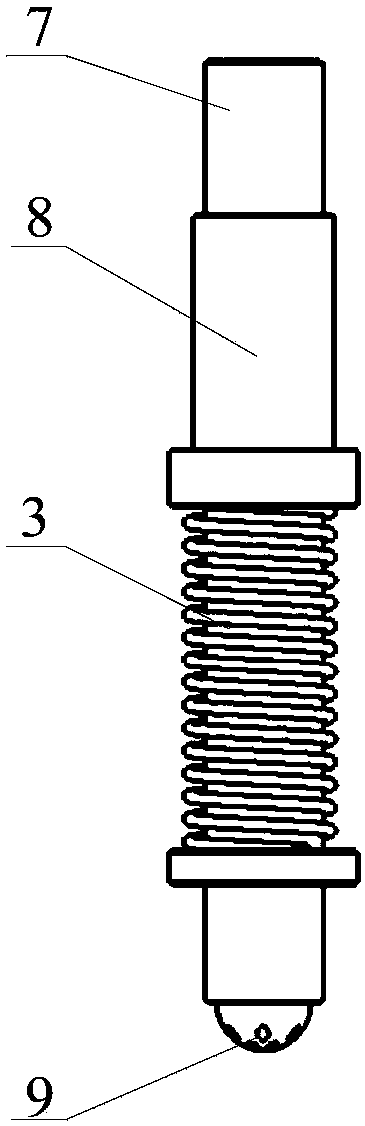

[0021] figure 2 In the detailed structure diagram of the floating tube electrode shown in the figure, there is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com