Small experimental circulating water tank

A circulating water tank and experimental technology, which is applied in the field of fluid mechanics research, can solve the problems that the top of the test section cannot be closed, the water tank is not easy to clean, and affects the flow field flow, etc., and achieves the effect of small size, convenient placement, and uniform and stable flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

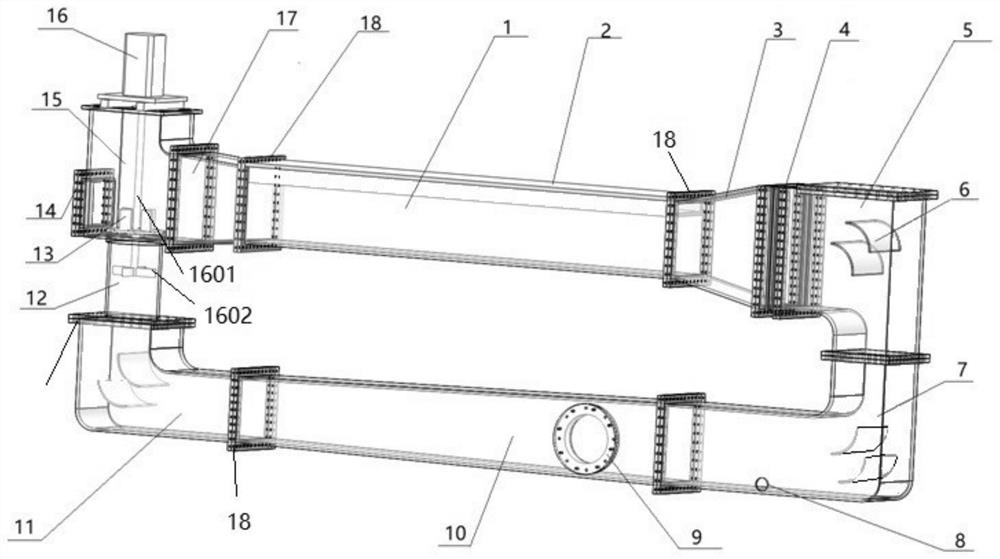

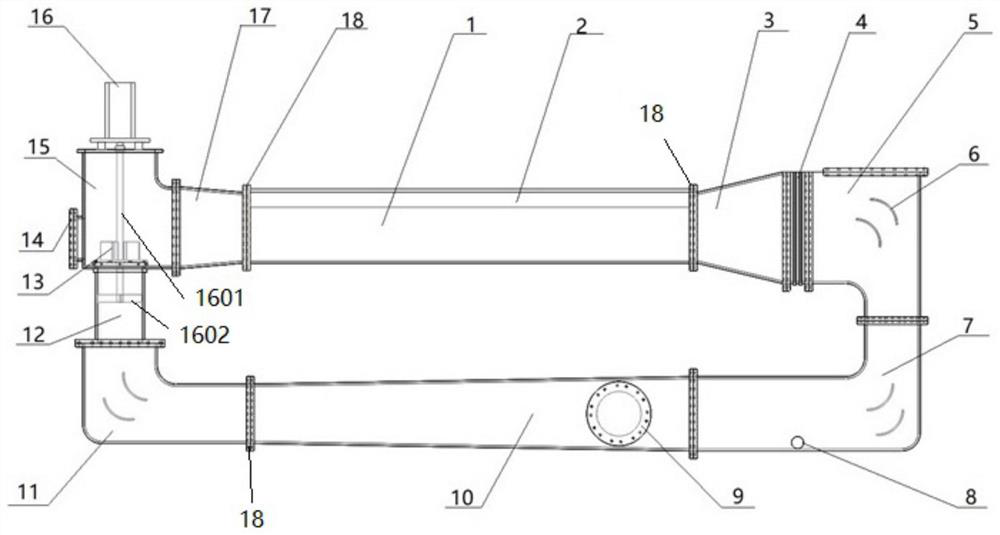

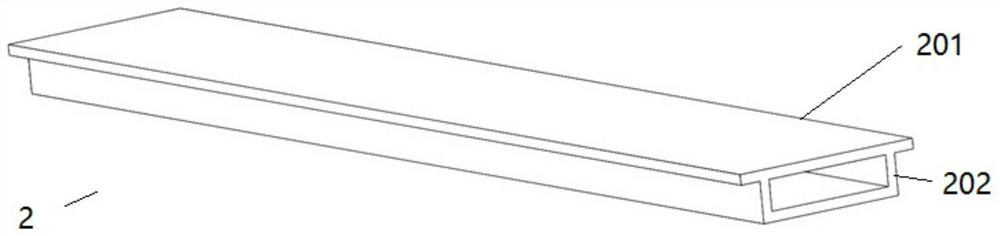

[0038] Such as figure 1 , 2 As shown, a small-scale experimental circulating water tank includes a horizontal water tank body, and the water tank body includes a test section 1, an upper expansion section 17, a power section 15, and a connecting section 12 that are sequentially connected to form a circuit (in this embodiment, a cylindrical shape is set. shape), the third-level guide section 11, the lower expansion section 10, the second-level guide section 7, the first-level guide section 5, the rectification section 4 and the contraction section 3, the test section 1 is set horizontally, and the upper expansion section 17 , the axes of the contraction section 3 and the rectification section 4 coincide with the axis of the test section 1, the axis of the lower expansion section 17 is parallel to the axis of the test section 1, and the lower expansion section 17 is located below the test section 1, and the upper expansion section 17, The contraction section 3, the rectificatio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com