Draft tube for single crystal furnace

A technology of a guide tube and a single crystal furnace, which is applied in the field of the guide tube, can solve the problems of increasing energy consumption, shaking of single crystal silicon rods, and strengthening of airflow intensity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

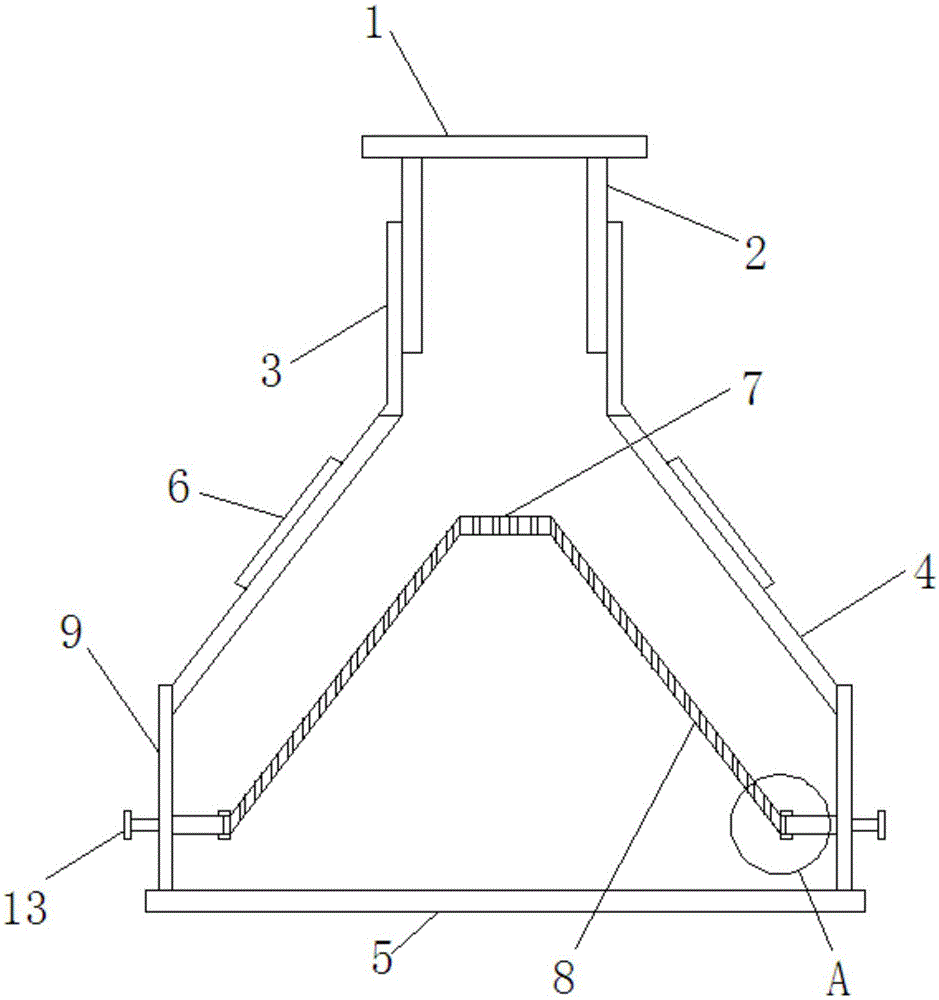

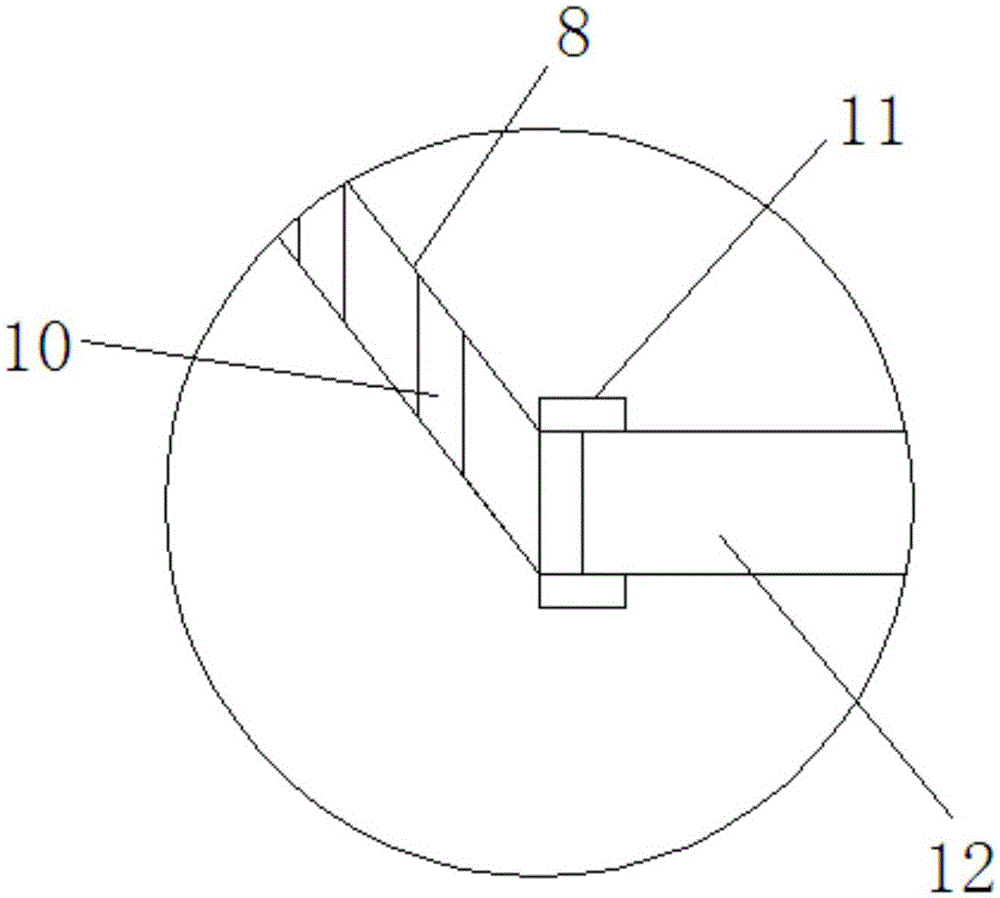

[0012] Such as figure 1 and figure 2 The shown guide tube for single crystal furnace includes a trumpet-shaped cylinder body 4, a feed flange 1 and a discharge flange 5, and the feed flange 1 and discharge flange 5 are respectively connected On the narrow-mouth end and the wide-mouth end of the horn-shaped cylinder 4, an extension device is arranged between the narrow-mouth end of the horn-shaped cylinder 4 and the feeding flange 1, and the described horn-shaped cylinder 4 A baffle 9 is arranged between the wide mouth end of the outlet and the discharge flange 5, and a baffle 9 is arranged inside the trumpet-shaped cylinder 4, and through holes 10 are evenly arranged on the baffle, and the A filter plate 12 is also arranged between the lower end of the deflector and the side wall of the horn-shaped cylinder 4, and an inspection port is also provided on the side wall of the horn-shaped cylinder 4, and the horn-shaped cylinder outside the inspection port An observation window...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com