Small-bending-moment steel bar concrete pole as well as production device and manufacturing process thereof

A technology for production equipment and concrete, applied in the direction of manufacturing tools, molds, strengthening molding, etc., can solve the problems of non-conformity of skeleton molding, high labor intensity, low work efficiency, etc., to improve labor productivity, increase product production quantity, process operation Simple, quick and convenient effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

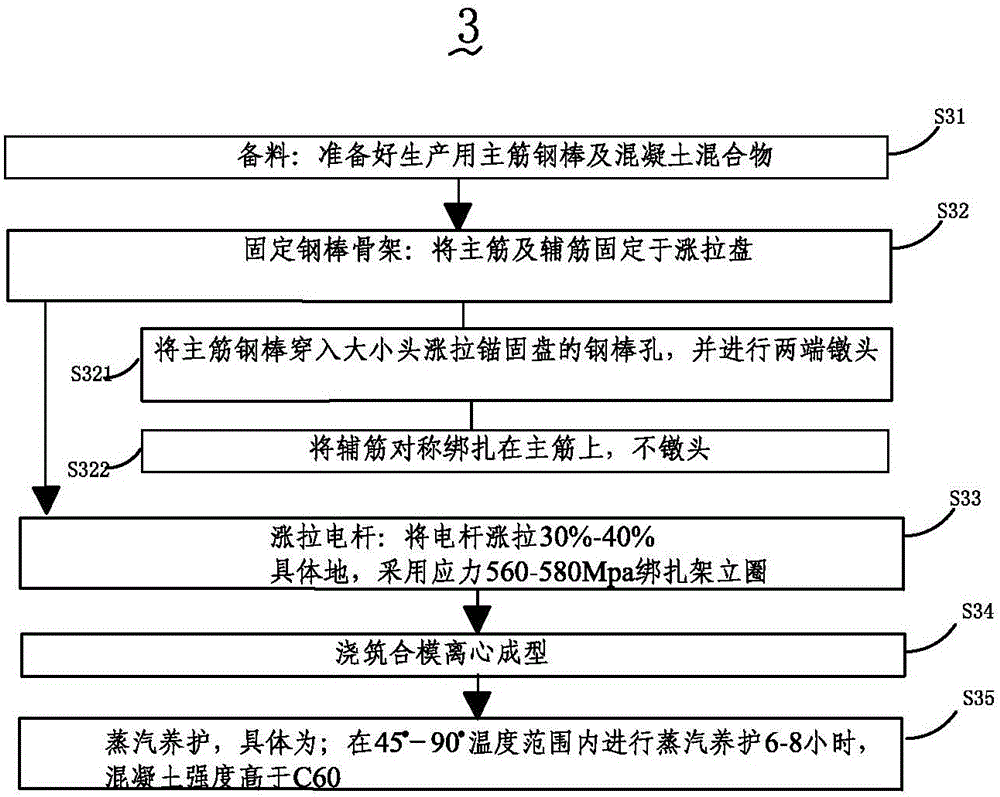

[0028] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the accompanying drawings in the embodiments of the present invention. Obviously, the described embodiments are only some, not all, embodiments of the present invention.

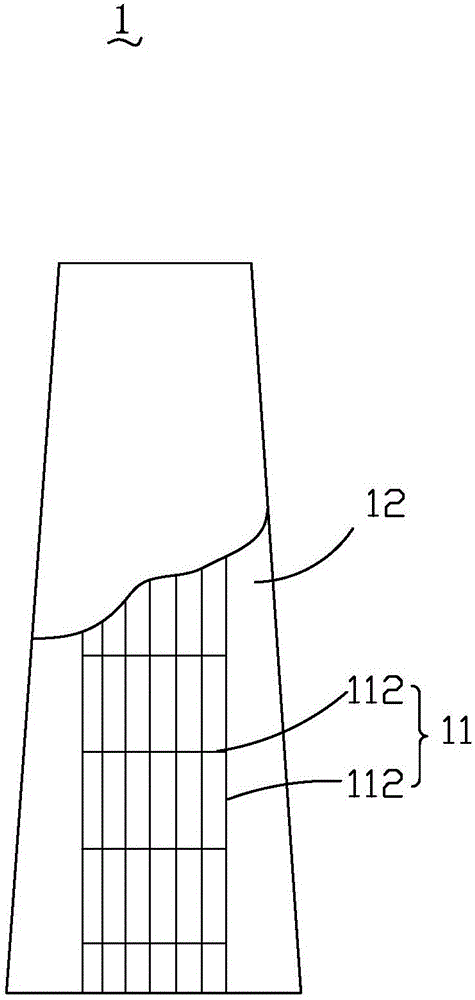

[0029] see figure 1 , is a structural schematic view of the small moment steel rod concrete pole provided by the present invention.

[0030] A small bending moment steel rod concrete pole 1 is a pole for a 10KV power grid, including a steel rod skeleton 11 and a concrete layer 12 . The concrete layer 12 wraps the steel rod skeleton 11 .

[0031] The steel bar skeleton 11 includes main reinforcements 111 and auxiliary reinforcements 112 . The number of the main reinforcement 111 and the auxiliary reinforcement 112 are multiple, and both are steel rods for prestressed concrete. A plurality of the main reinforcements 111 are axially arranged inside the small-moment s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com