Preparation method of high-density oxide dispersion strengthened steel

A technology of dispersion strengthening and oxide, which is applied in the field of preparation of high-density oxide dispersion strengthening steel, and can solve the problems that the performance of ODS steel cannot meet the ideal requirements for use.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

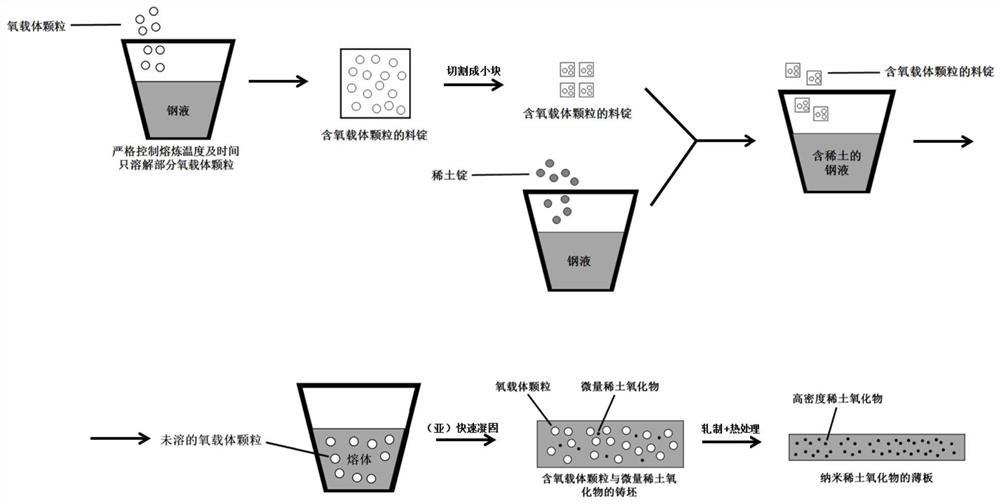

[0035] Such as figure 1 As shown, a method for preparing high-density oxide dispersion-strengthened steel uses a combination of smelting, rolling and heat treatment processes to prepare ODS steel, including the following steps:

[0036] 1. Put the steel matrix in the crucible for melting, vacuumize the furnace cavity, wash the gas twice under low vacuum conditions, and then pump high vacuum to 5×10 -3 Pa, and backfill with argon to 0.05MPa to form a protective atmosphere. Turn on the smelting power supply, adjust the current, observe the smelting situation, and wait until the steel raw materials in the crucible are completely melted to form a uniform molten steel. Add oxygen carrier particles directly into the molten steel, control the melting temperature to the set temperature (determined according to the melting point of the steel matrix), add oxygen carrier particles and then smelt for a certain period of time (determined according to the condition of the oxygen carrier part...

Embodiment 1

[0043] Option to use 316L as steel substrate, TiO 2 As the oxygen carrier particles, Y block is selected for rare earth, and 316L-ODS steel is synthesized by melting + solid state reaction.

[0044] The percentage of steel components in the total mass: C: 0.03%, Si: 1.00%, Mn: 2.00%, P: 0.045%, S: 0.03%, Cr: 16.0%, Ni: 12.0%, Mo: 2.00%, Y: 0.2%, Ti: 0.25%, and the balance is Fe and unavoidable impurities.

[0045] The specific operation steps are as follows:

[0046] 1. Put 316L in the crucible, vacuumize the furnace cavity, wash the gas twice under low vacuum conditions, and then pump high vacuum to 5×10 -3 Pa, and backfill with argon to 0.05MPa to form a protective atmosphere. Turn on the smelting power supply, adjust the current, and observe the smelting situation. The smelting temperature is about 1500°C, and the smelting time is 1 to 5 minutes. After the raw materials in the crucible are completely melted, the molten steel is smelted in the crucible. At this time, the...

Embodiment 2

[0050] Choose to use pure iron as the substrate, TiO 2 As the oxygen carrier particles, Er block is selected as the rare earth, and ODS steel is synthesized by smelting + solid state reaction.

[0051] The percentage of steel components in the total mass: C: 0.03%, Si: 1.00%, Mn: 2.00%, P: 0.045%, S: 0.03%, Cr: 16.0%, Ni: 12.0%, Mo: 2.00%, Er: 0.2%, Ti: 0.25%, and the balance is Fe and unavoidable impurities.

[0052] The specific operation steps are as follows:

[0053] 1. Put pure iron in the crucible, vacuumize the furnace cavity, wash the gas twice under low vacuum conditions, and then pump high vacuum to 5×10 -3 Pa, and backfill with argon to 0.05MPa to form a protective atmosphere. Turn on the smelting power supply, adjust the current, and observe the smelting situation. The smelting temperature is about 1600°C, and the smelting time is 1 to 5 minutes. After the raw materials in the crucible are completely melted, the molten steel is smelted in the crucible. At this ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

| compressive strain | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com