Circuit board capable of preventing contact of a gold finger and solder

A gold finger and circuit board technology, which is applied in printed circuit, printed circuit, printed circuit manufacturing, etc., can solve the problems of increasing manpower and working hours of manufacturing process workstations, solder mask tape costs, poor tinning efficiency, and increased manufacturing costs. Achieve the effect of reducing manufacturing unit time, increasing production quantity, and avoiding tin sticking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

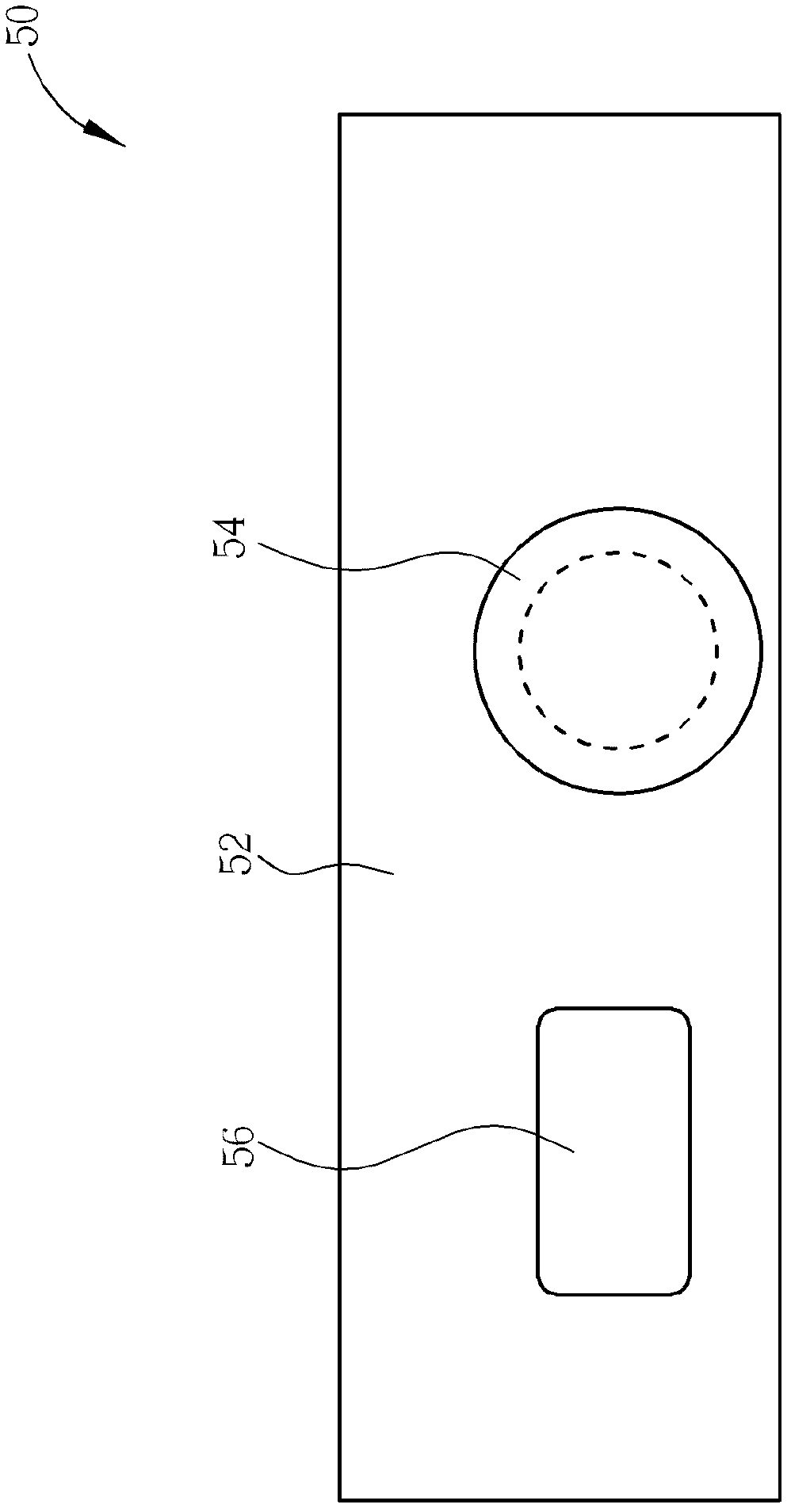

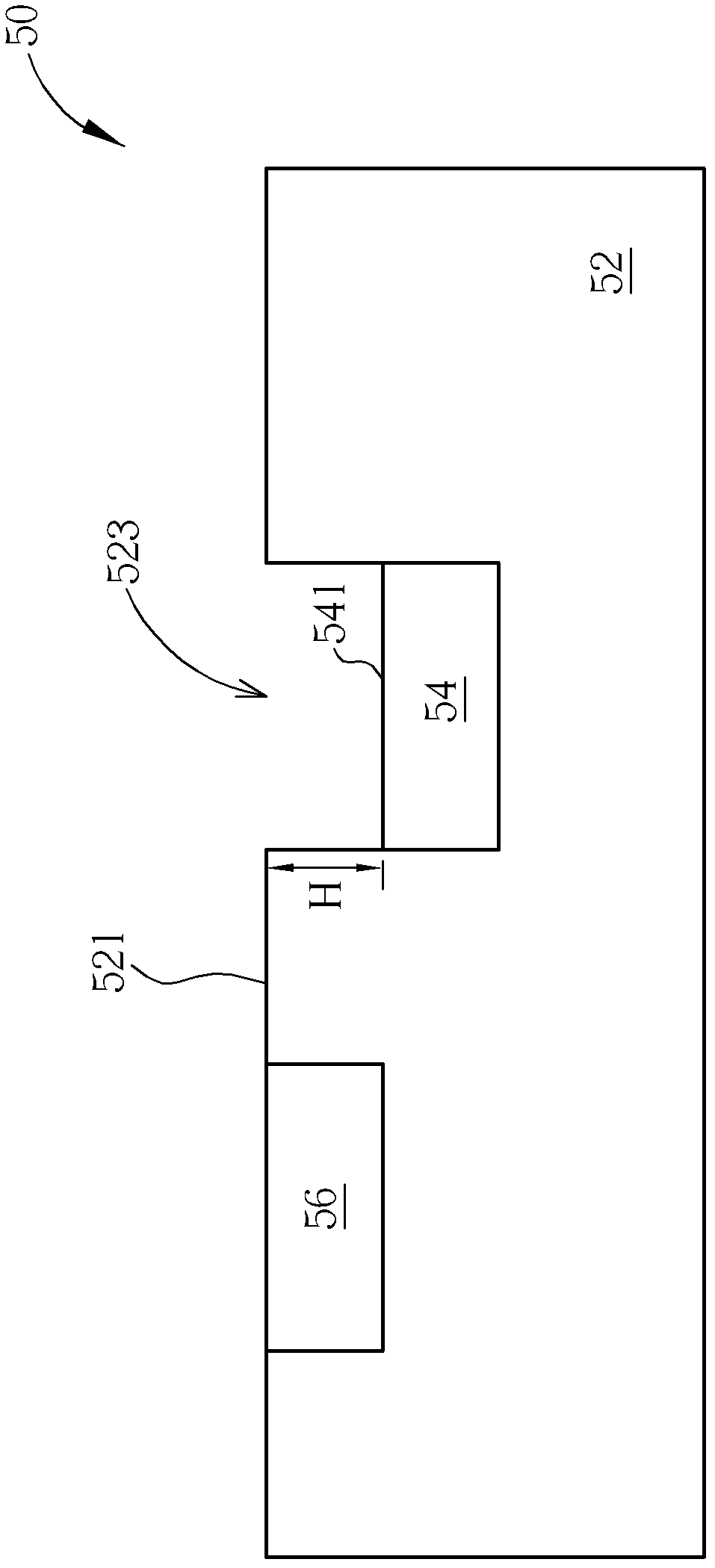

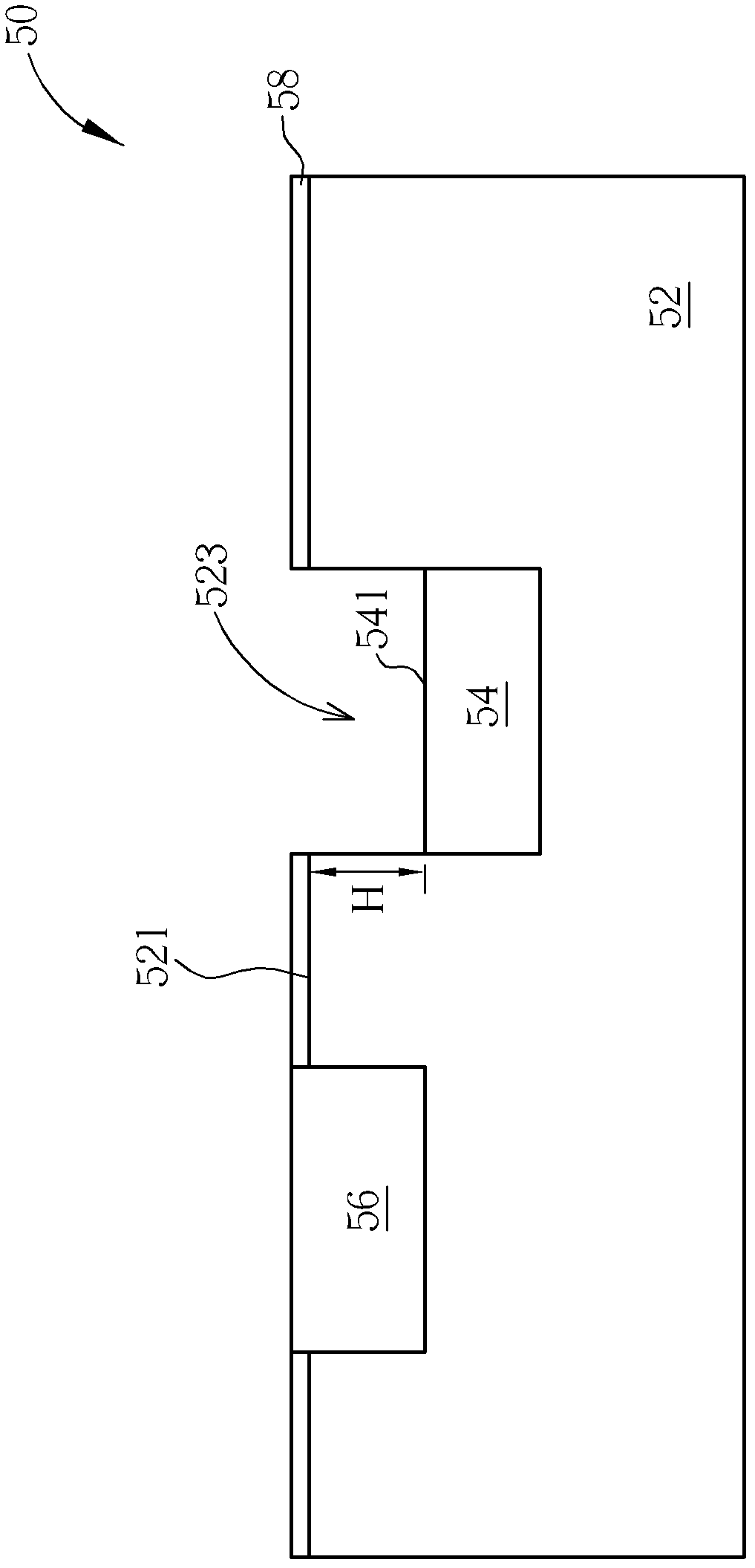

[0025] see figure 1 and figure 2 , figure 1 and figure 2 They are respectively a schematic top view and a schematic cross-sectional view of the circuit board 50 according to Embodiment 1 of the present invention. The circuit board 50 includes a substrate 52, which has a surface 521 and a recess 523 formed thereon; the circuit board 50 further includes a gold finger structure 54, which is arranged in the recess 523 of the substrate 52. There is substantially a height difference H between the top surface 541 and the surface 521 of the substrate 52, wherein the height difference H between the top surface 541 of the gold finger structure 54 and the surface 521 of the substrate 52 can be substantially greater than the particle size of the solder paste particles, for example Generally speaking, the powder particle size of printing solder paste used in the industry is about 20 microns to 38 microns, so the height difference H between the top surface 541 of the gold finger struct...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com