High-efficiency photovoltaic solar module welding equipment

A photovoltaic solar energy and component technology, applied in welding equipment, photovoltaic power generation, metal processing equipment, etc., can solve problems such as bottleneck restrictions, and achieve the effect of reducing operating actions, improving product output, and improving manufacturing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

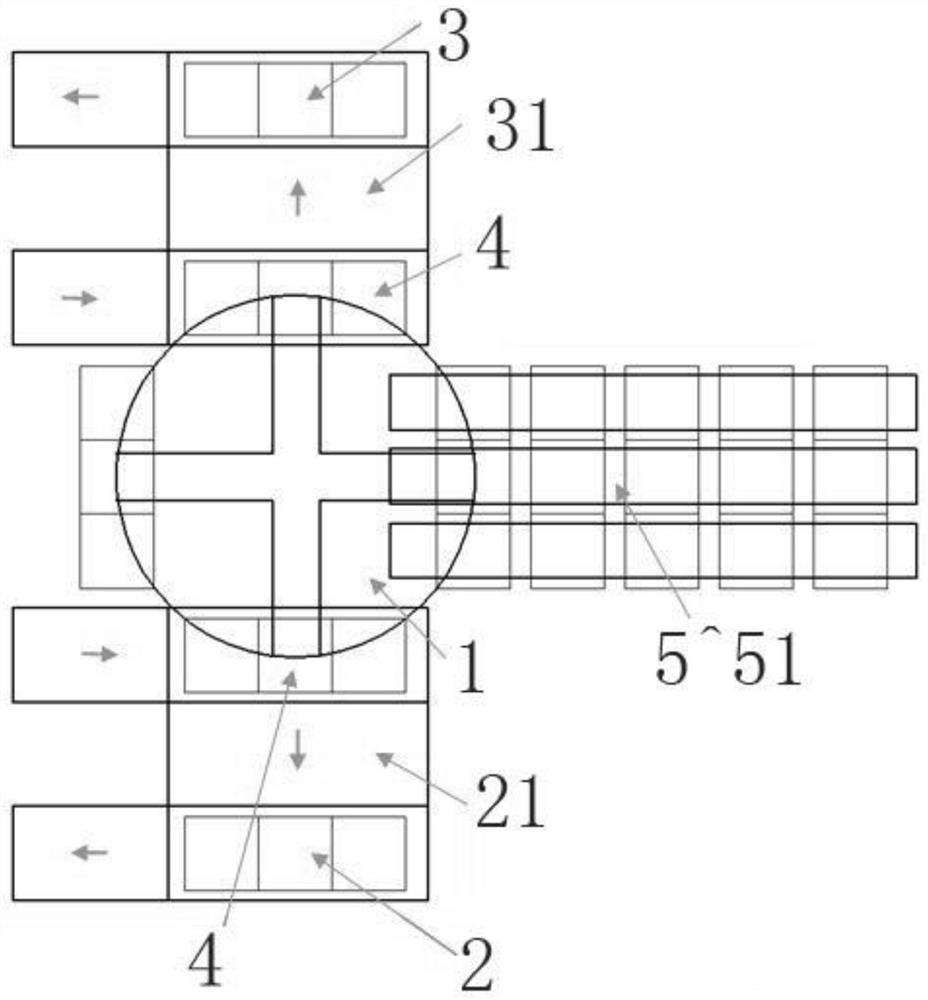

[0037] see Figure 1 to Figure 4 This embodiment shows a kind of high-efficiency photovoltaic solar module welding equipment:

[0038] The charging module 1 is symmetrically arranged on the battery sheet feeding and conveying assembly a 2 and the battery sheet feeding and conveying assembly b 3 on the side of the charging module 1, and is connected with the battery sheet feeding and conveying assembly a 2 and the battery sheet. The battery chip spraying flux delivery assembly 5 that is set correspondingly to the material delivery assembly b 3 and used in conjunction with the feeding module;

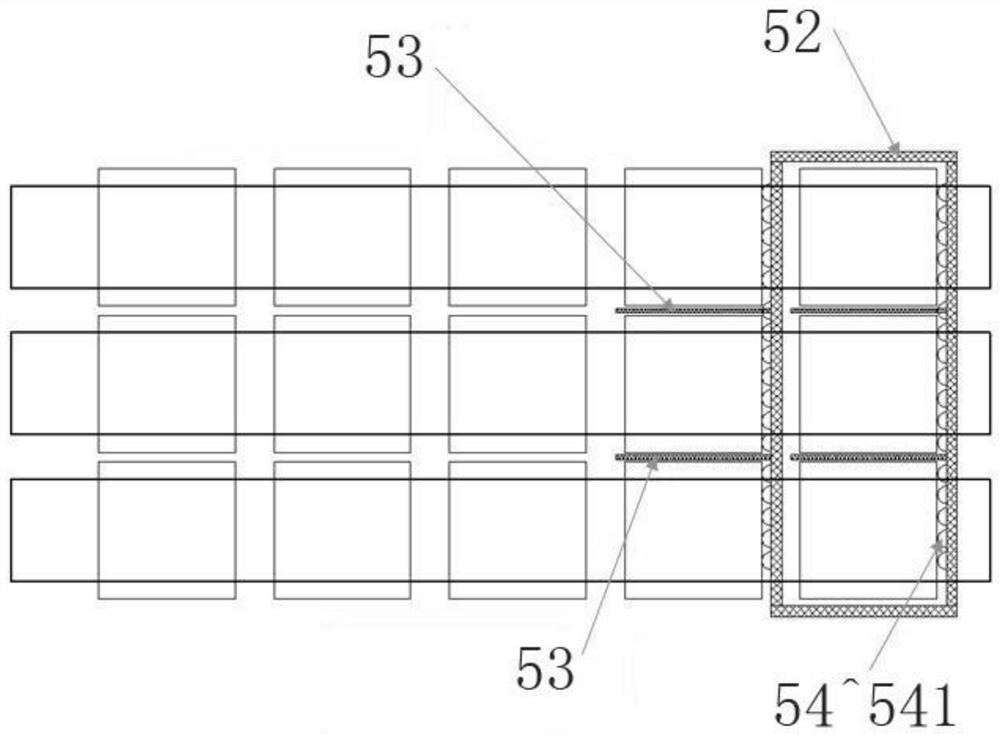

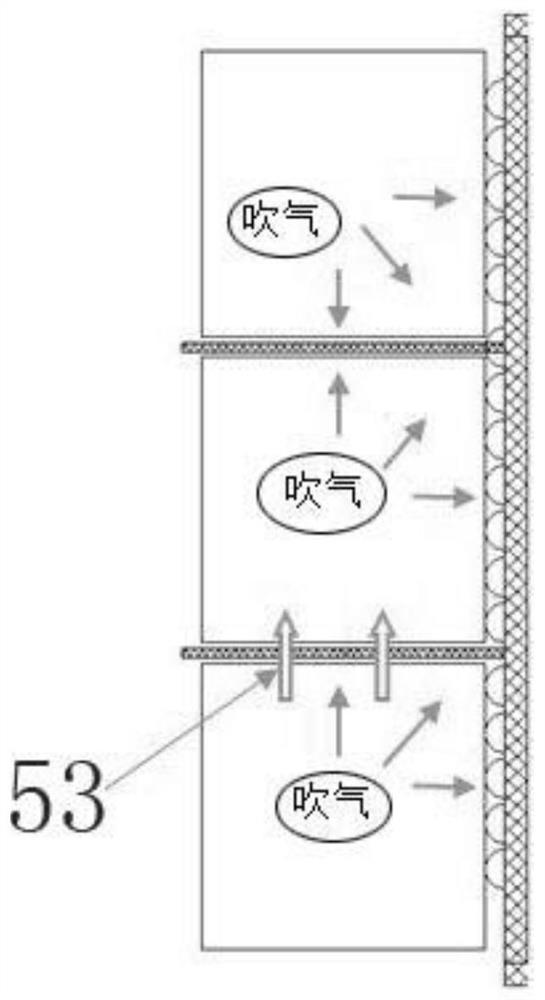

[0039] The cell spray flux delivery assembly 5 includes a plurality of correspondingly arranged cell spray flux delivery lines 51 , and a set at the end of the cell spray flux delivery line 51 for absorbing and blowing the cells. The integrated cell lifting and positioning platform 52, and the positioning baffles 53 are arranged between two correspondingly arranged cell spraying flux del...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com