Water tank for electric rice cooker, manufacturing method of water tank and electric rice cooker

A manufacturing method and water tank technology, which are applied in the field of household electrical appliances, can solve the problems of increased shell materials, unsightly appearance, and waste of cost, and achieve the effects of saving space, beautiful appearance of product technology, and reducing the rate of defective manufacturing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] In the following Detailed Description, reference is made to the accompanying drawings which form a part hereof. The aspects of the invention generally described herein and illustrated in the drawings may be permuted, substituted, combined, Splits and deletions, all such permutations, substitutions, combinations, splits and deletions fall within the scope of the present invention.

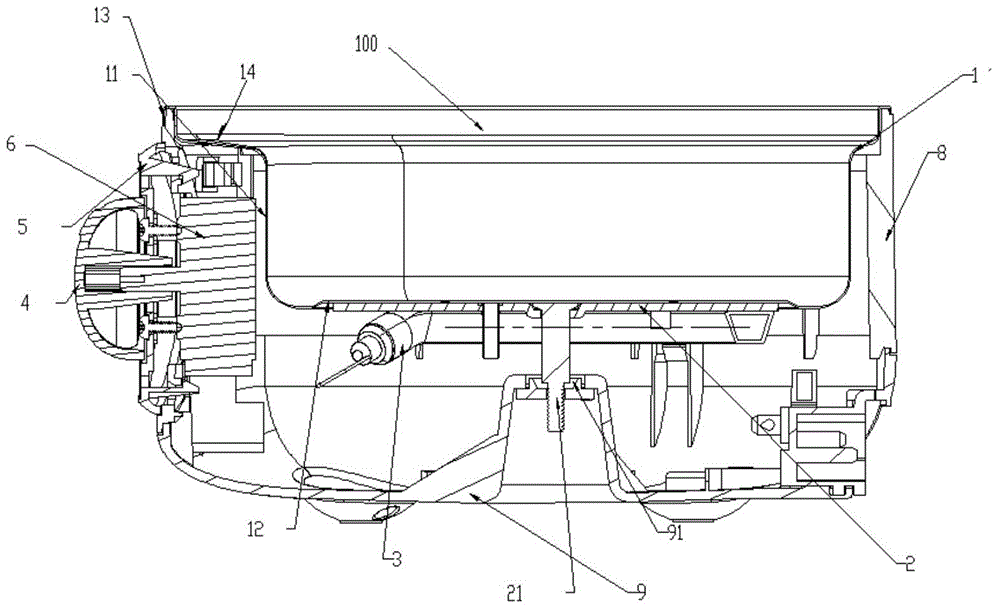

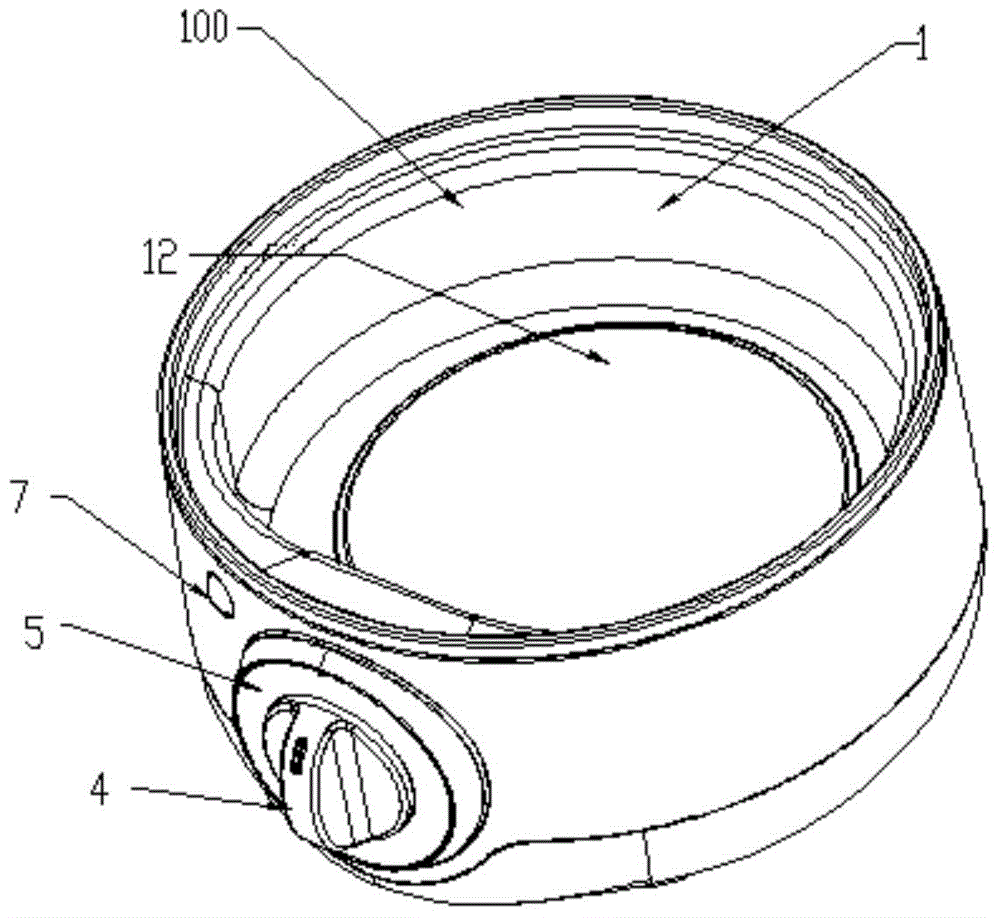

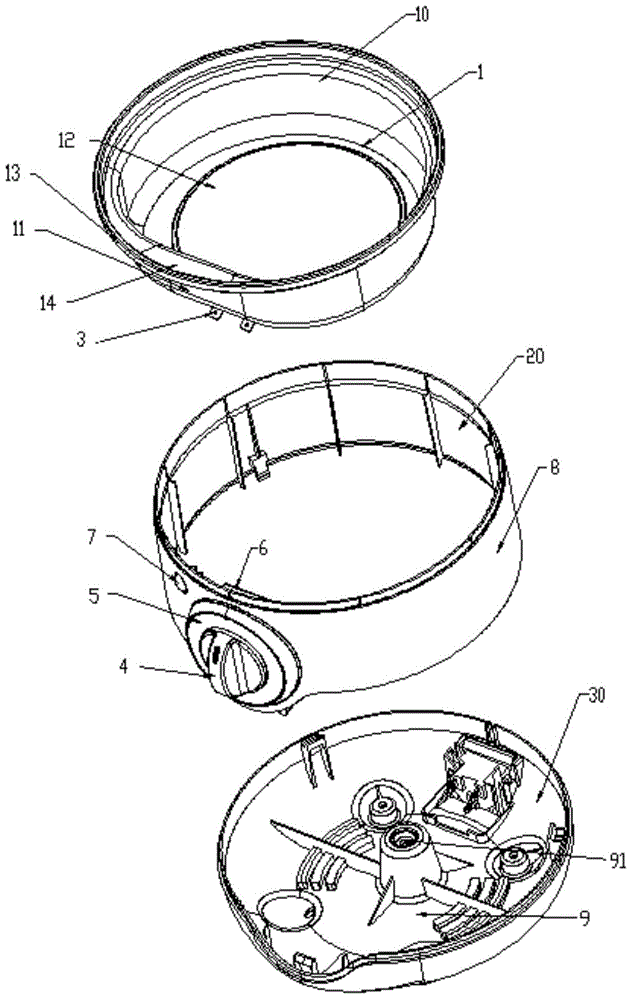

[0030] figure 1 is a sectional view of a base assembly 100 of an electric cooker according to an embodiment of the present invention, and figure 2 is a perspective view of a base assembly 100 of an electric cooker according to an embodiment of the present invention. Such as figure 1 with Figure 4 As shown, the tank has a peripheral wall with an opening, preferably a generally cylindrical peripheral wall. The peripheral wall of the water tank is provided with an escape portion 11 at a position facing the control portion 5 of the electric pot, and the escape portion 11 constitutes a radi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com