Bonding device

A welding device and welding point technology, applied in welding equipment, auxiliary devices, manufacturing tools, etc., can solve the problems of increasing proportion and difficulty in shortening welding time, and achieve the effect of increasing production quantity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

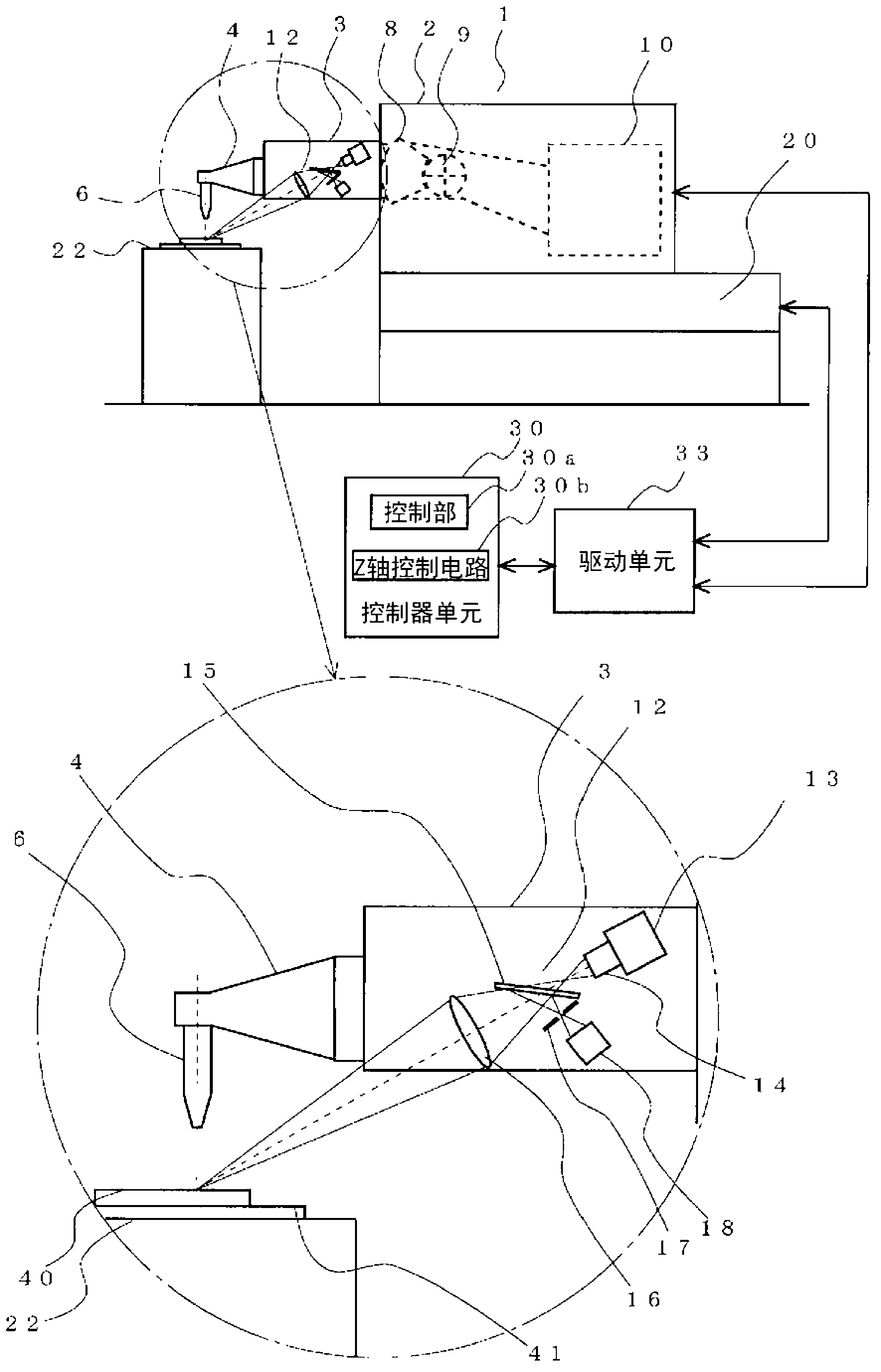

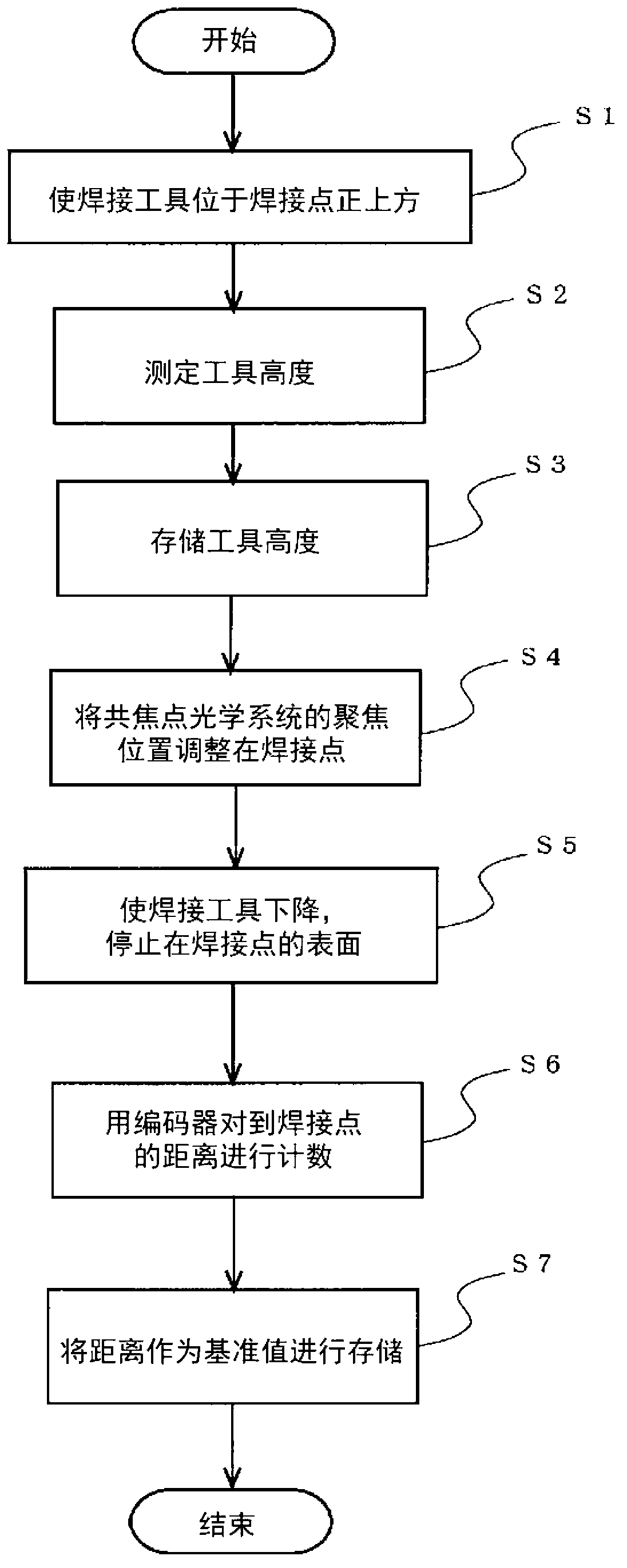

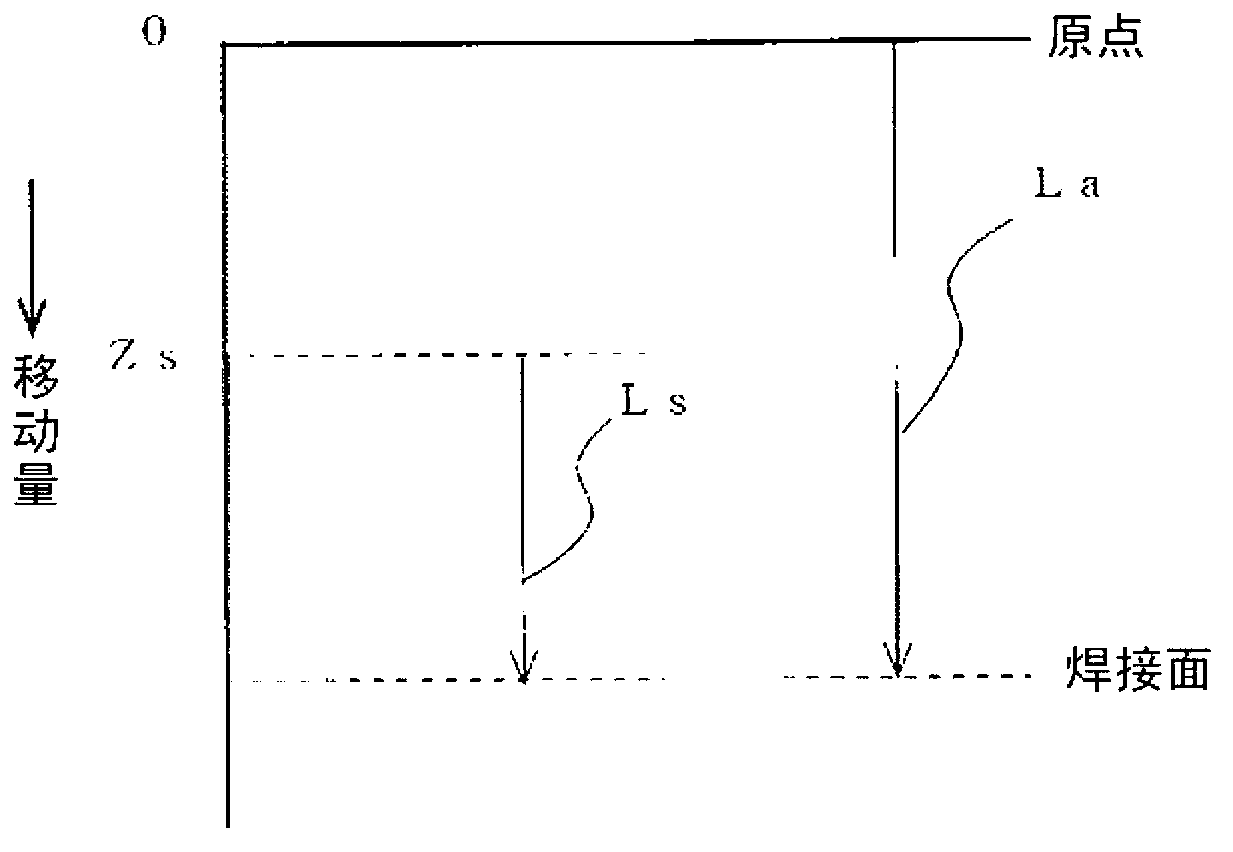

[0052] Hereinafter, embodiments of the welding device according to the present invention will be described with reference to the drawings. In addition, as the bonding device, a wire bonding device for connecting a pad as a first bonding point and a lead as a second bonding point with a gold wire or the like will be described.

[0053] [Structure of Welding Device]

[0054] figure 1 It is a figure including a partial enlarged view showing the structure of the welding apparatus of the present invention. Additionally, for Figure 7 The same components as those of the conventional wire welding apparatus shown are denoted by the same reference numerals, and a detailed description of the structure is omitted.

[0055] like figure 1 As shown, the wire welding device 1 includes: a welding head 2; an XY stage 20 that carries the welding head 2 and can move in the two-dimensional direction of the XY axis; A welding platform 22 of the frame; and a controller unit 30 for controlling...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com