Automatic insert equipment of nut

An automatic nut insertion technology, applied in the direction of metal processing equipment, metal processing, manufacturing tools, etc., can solve the problems of crimping cylinder damage, long working hours, nuts cannot be inserted into the display shell, etc., to increase production quantity, prevent failures and broken effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] Hereinafter, an embodiment of the present invention using a general support frame having mutually symmetrical nut portions formed on one side and two nuts respectively inserted will be described in detail with reference to the accompanying drawings.

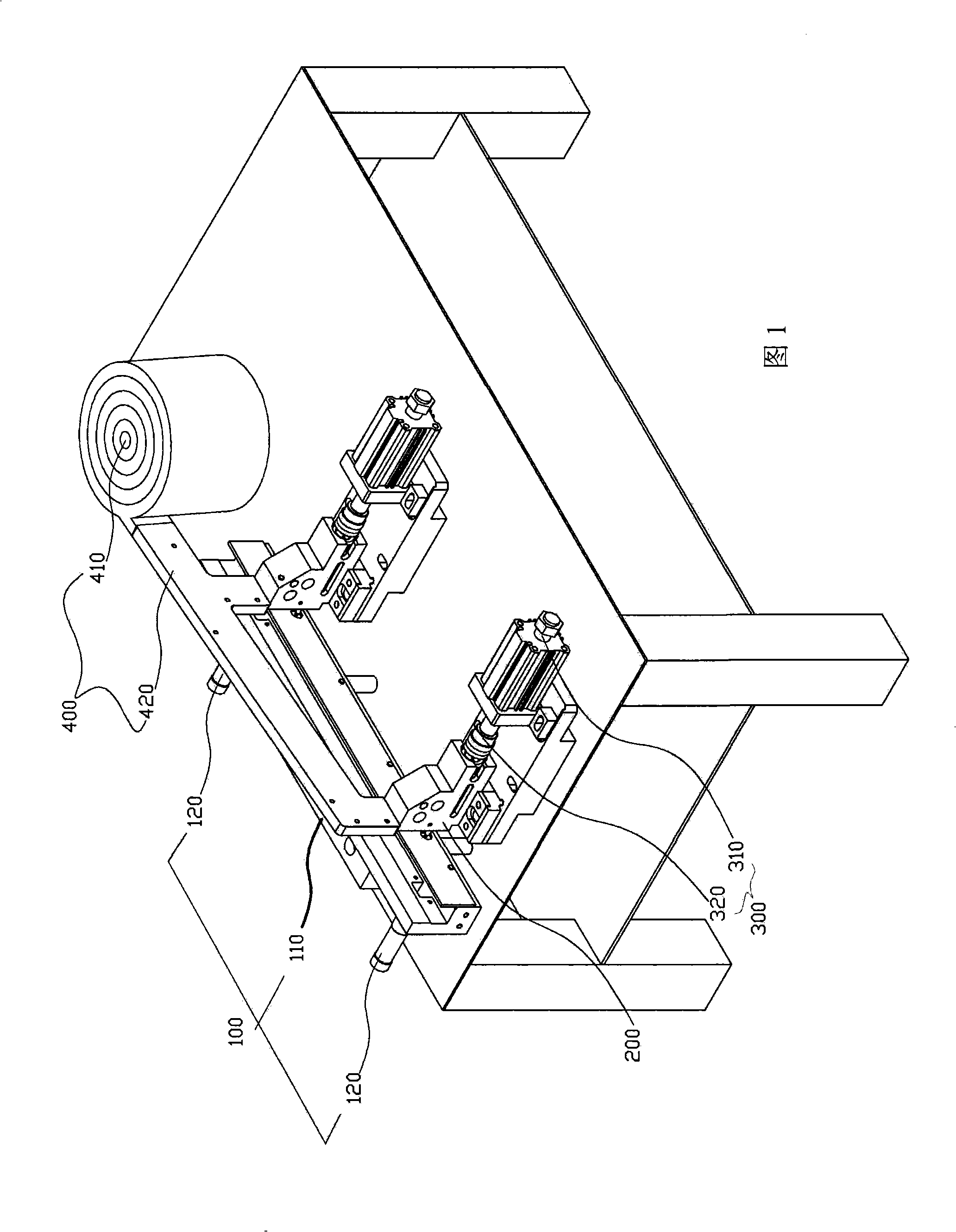

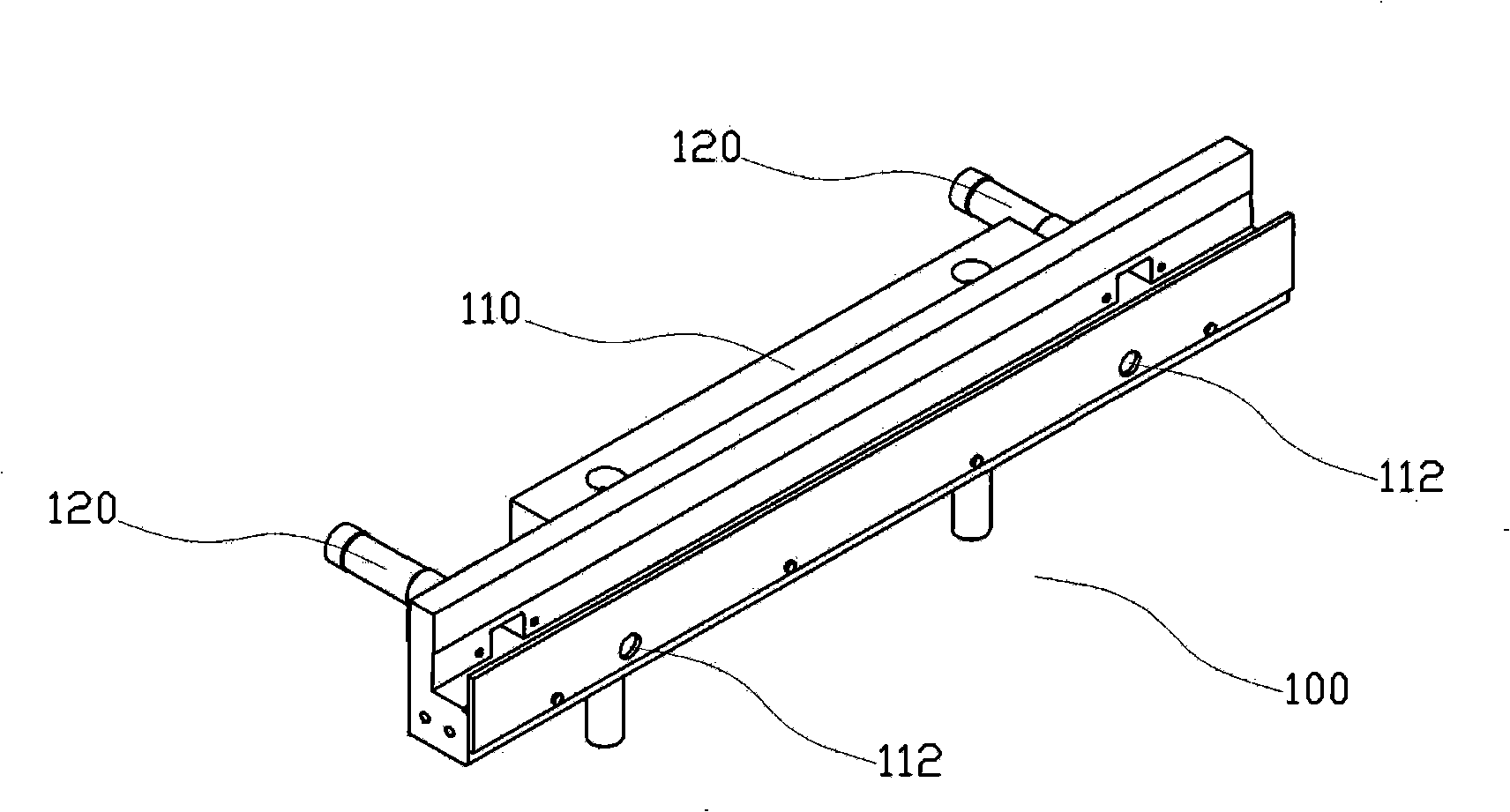

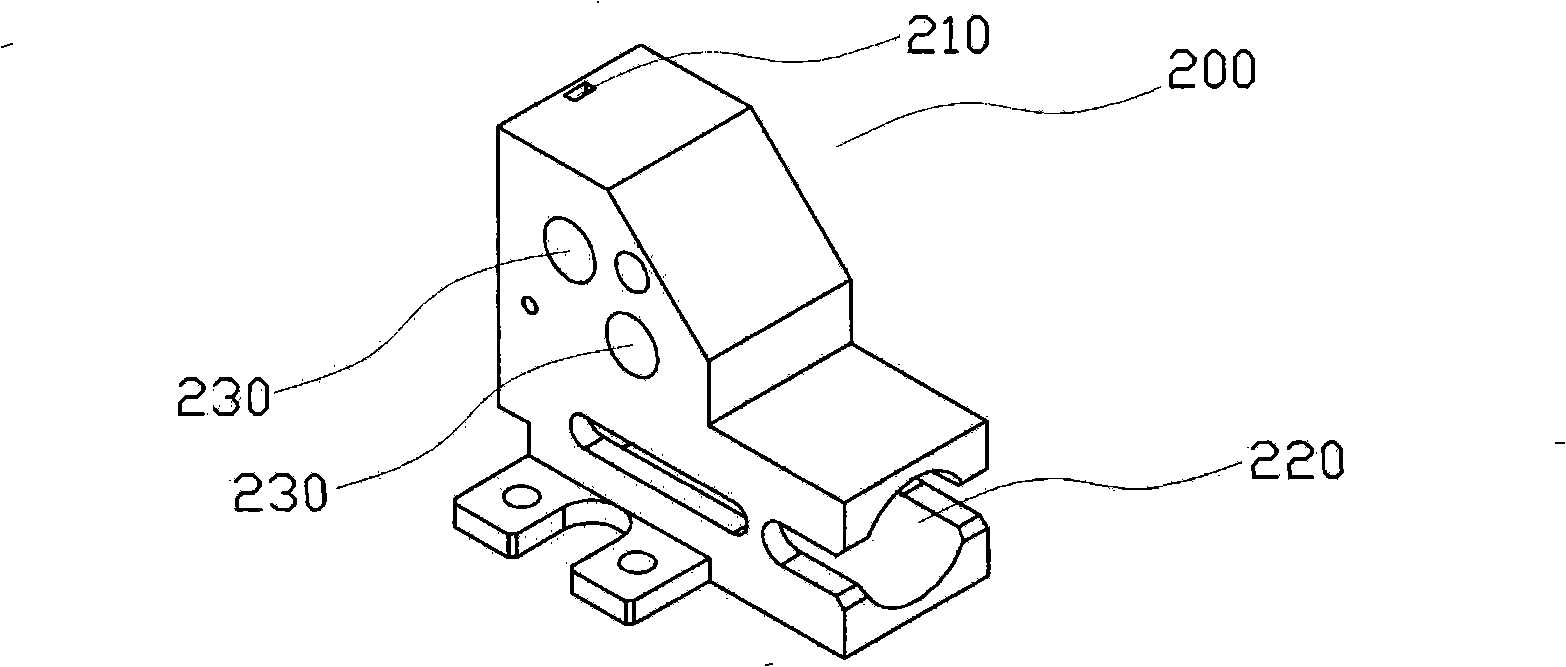

[0022] Fig. 1 is the three-dimensional schematic diagram of the embodiment of the present invention; figure 2 It is a detailed three-dimensional schematic diagram of the fixture of the present invention; image 3 It is a detailed structural perspective view of the preheater of the present invention; Figure 4 It is a three-dimensional schematic diagram of the detailed structure of the inserter 320 of the present invention; Figure 5 It is a three-dimensional schematic diagram of the detailed structure of the feeder of the present invention; Figure 6 It is a three-dimensional schematic diagram of the combination relationship between the interposer 320 and the preheater 200 of the present invention; Figure 7 It is a sch...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com