Drum type chip burning equipment

A burning equipment, drum-type technology, applied in the direction of conveying record carriers, instruments, computer parts, etc., can solve the problems of insufficient IC placement of IC burning equipment, increasing burning time, and decreasing production speed.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

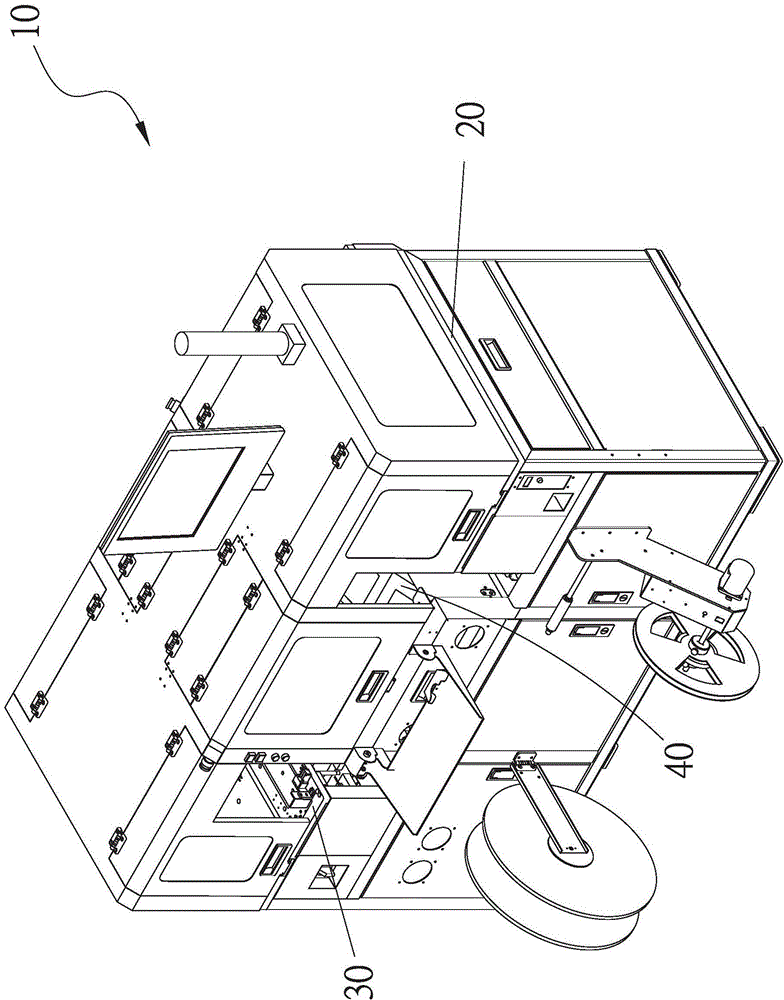

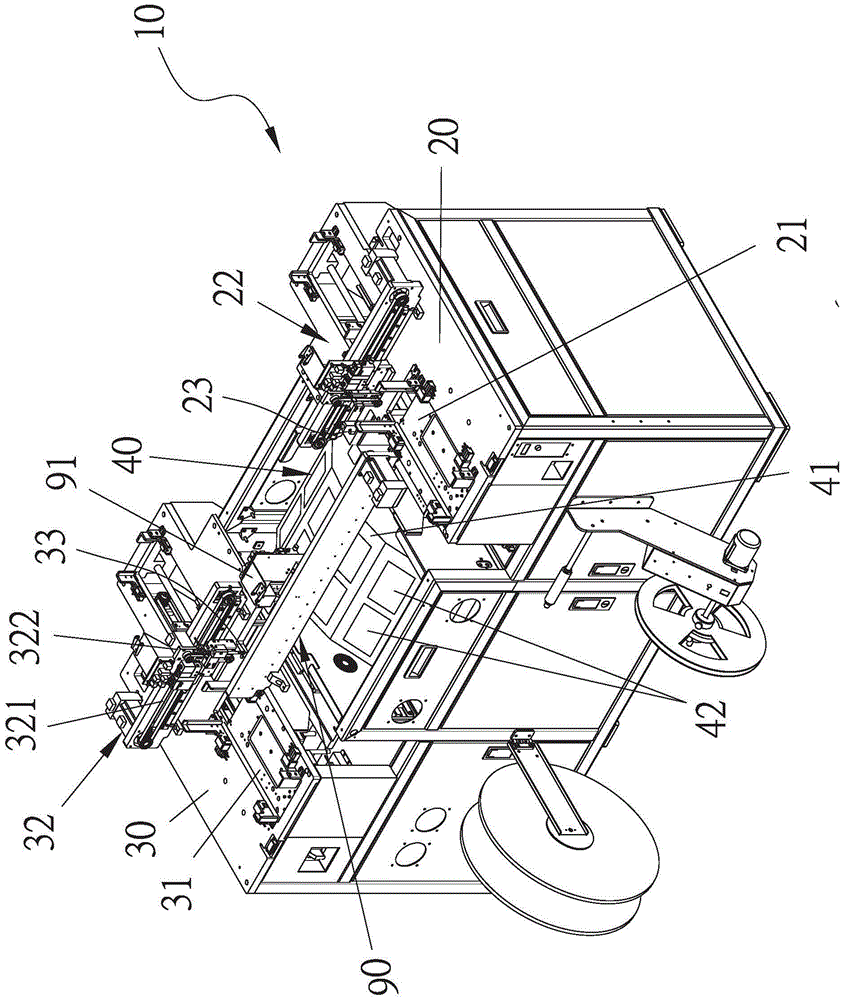

[0044] see figure 1 , figure 2 As shown, the present invention provides a drum-type chip programming device, which includes:

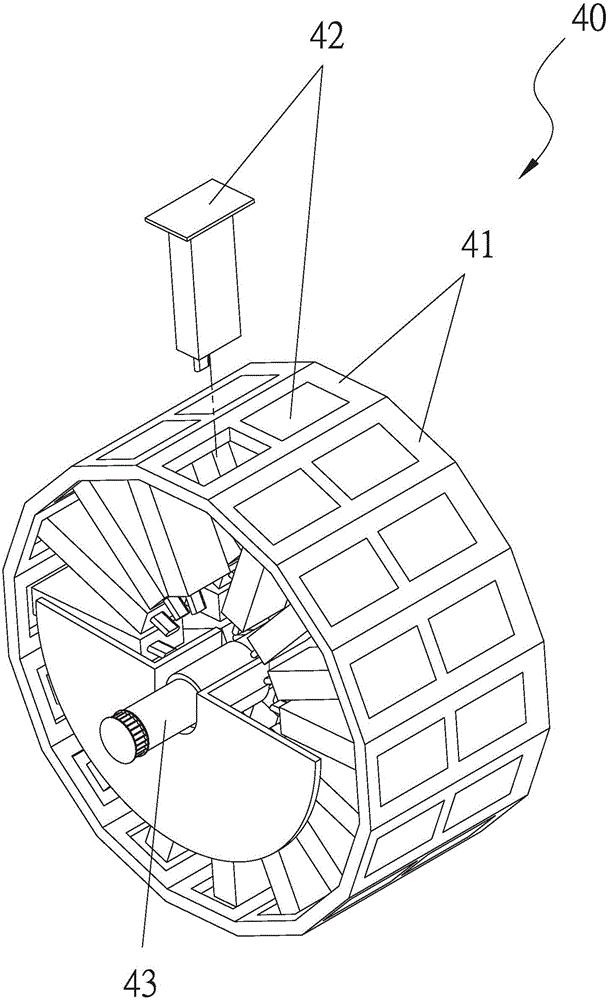

[0045] Burning equipment 10, this burning equipment 10 is provided with the first working platform 20, the second working platform 30, the drum type burning device 40, the pick-up device 90, and this first working platform 20 is provided with the material seat Moving device 202, and the first working platform 20 is provided with a first material placement part 21, and the first material placement part 21 can be arranged on the material placement seat displacement device 202, and as Figure 5 As shown, the first working platform 20 is provided with a feeding device 22, and the feeding device 22 is provided with a lateral displacement device 221, and the lateral displacement device 221 is provided with a longitudinal displacement device 222, and the longitudinal displacement device 222 is provided with a second A feeding suction nozzle 23, and as Fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com