Wastewater treatment method and system

A wastewater treatment system and treatment method technology, applied in water/sewage treatment, heating water/sewage treatment, degassed water/sewage treatment, etc., can solve problems such as environmental pollution, soil and surface water, groundwater damage, etc., to improve Mass transfer heat transfer efficiency, avoid fouling blockage, avoid fouling effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

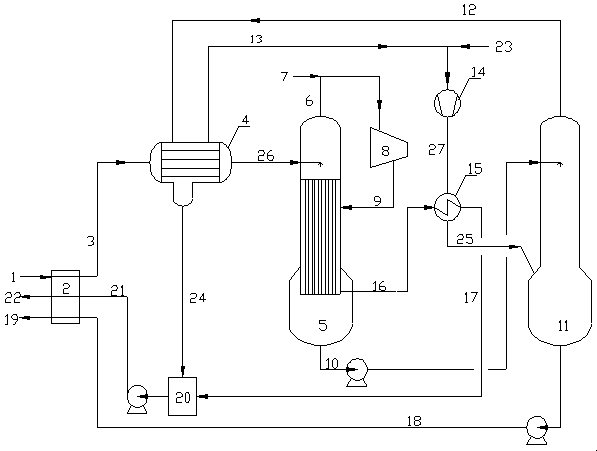

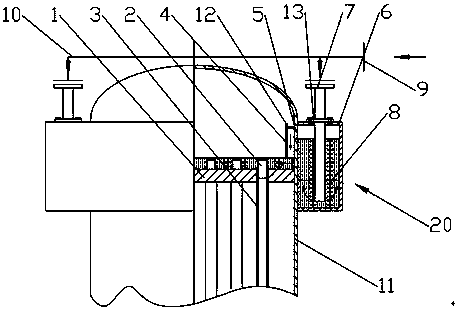

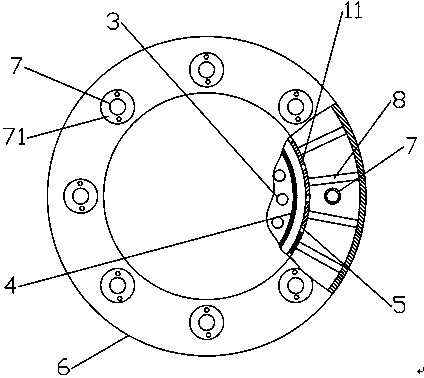

[0075] use figure 1 The system, the evaporator adopts figure 2 In the device, the waste water used is FCC desulfurization waste water. The waste water mainly contains sodium sulfite, sodium sulfate and calcium carbonate salt. The salt concentration of the raw waste water is 6wt%, and the treatment capacity of the raw waste water is 30t / h. Preheating, the heater 4 is heated to 100° C., and enters the evaporator 5 . The compression ratio of the steam compressor 8 is 1.4, and nitrogen is used as supplementary non-condensable gas. The concentrated liquid 10 discharged from the bottom of the evaporator 5 is 16 wt%. After the concentrated liquid 10 is stripped and evaporated by the stripper 11, the concentrated liquid 17 discharged is 24 wt%. The temperature of the condensed water 21 after heat recovery is about 45°C, and the recovered condensed water is 16.6 t / h.

PUM

| Property | Measurement | Unit |

|---|---|---|

| compression ratio | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com