Railway vehicle control relay panel

A technology for controlling relays and rail vehicles. It is used in locomotives, substations/switchgear boards/panels/desks, etc. It can solve problems such as non-compliance with industrial electrical equipment requirements, electrical system failures, and easy deformation of sub-boards, and achieve enhanced strength. , the effect of increasing the strength and increasing the number of layouts

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

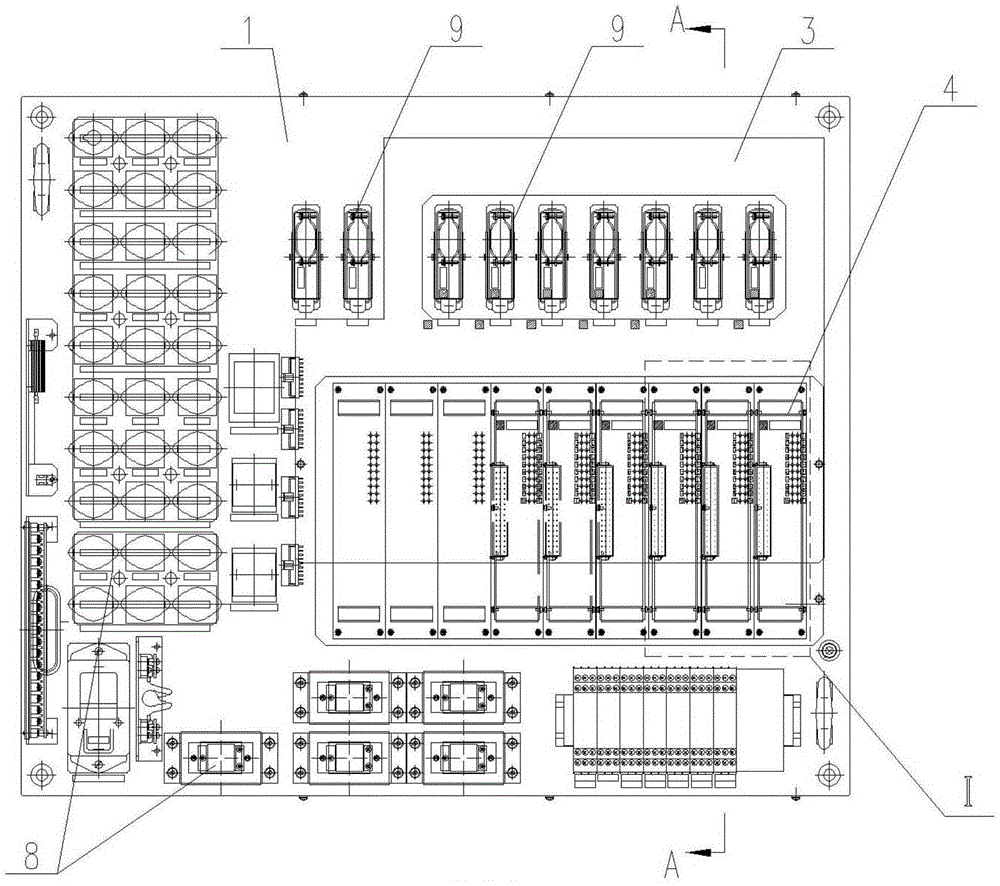

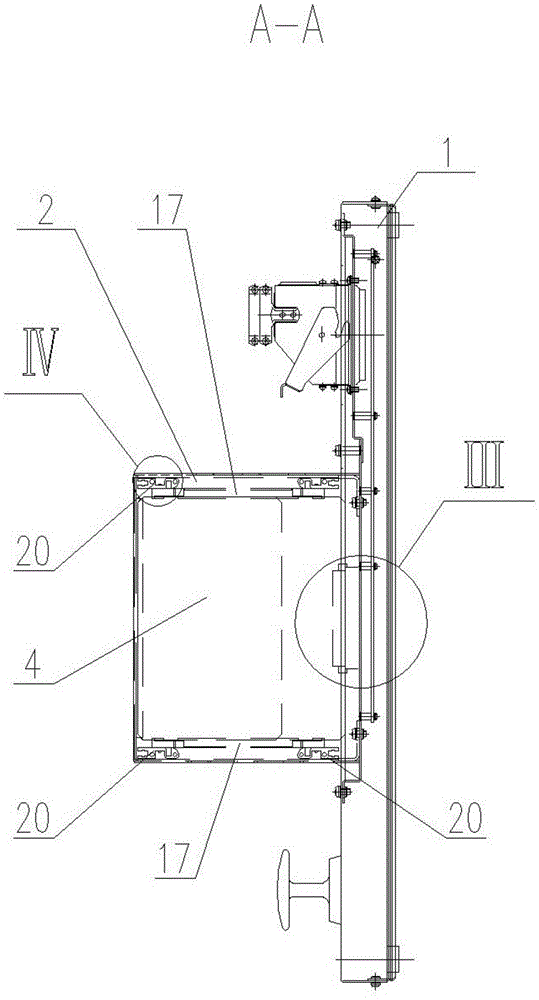

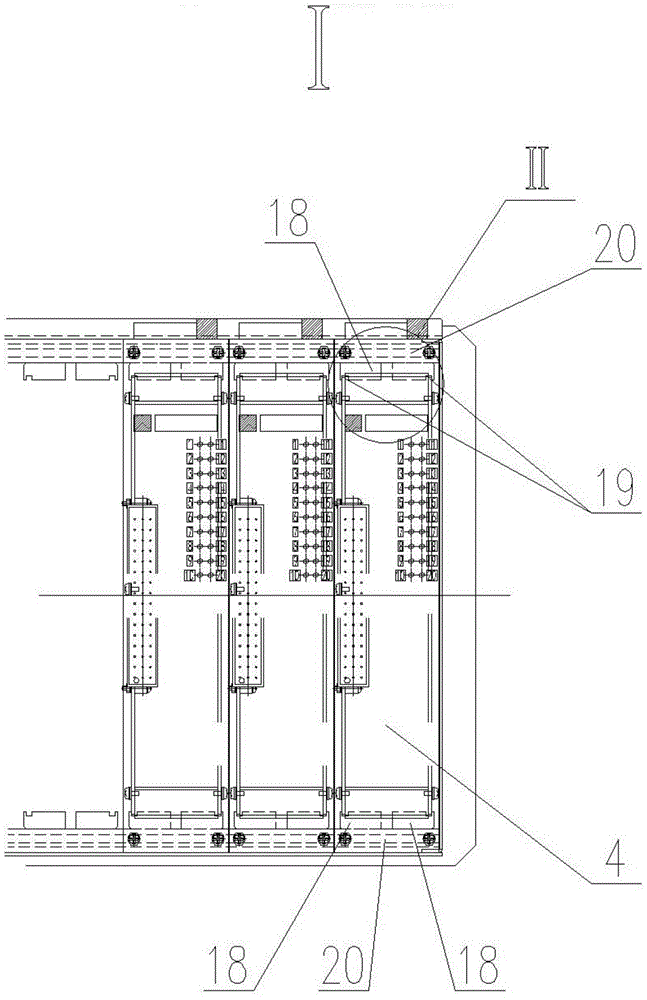

[0031] like Figure 1 to Figure 6 As shown, a rail vehicle control relay panel includes a main frame. The main frame includes a panel mounting frame 1 and a sub-board mounting frame 2 . The sub-board mounting frame 2 protrudes from the panel mounting frame 1 .

[0032] The panel installation framework 1 includes a square box body, the bottom surface of which is a detachable bottom plate, the motherboard 3 is bolted into the square box body, and the bottom plate is provided to facilitate the installation and disassembly of the motherboard 3 .

[0033] A sub-board installation framework 2 is arranged on one side of the square box body. The sub-board installation framework 2 protrudes from the panel installation framework 1 and is perpendicular to it. The sub-board installation framework 2 includes a cuboid frame, and the cuboid frame and the panel installation framework 1 are integrated. , multiple groups of chute assemblies 17 for inserting the sub-board assembly 4 are arranged...

Embodiment 2

[0047] like Figure 10 As shown, the difference between this embodiment and Embodiment 1 is that a plurality of first connectors 9 are also provided on the panel mounting frame 1 , and some sub-board assemblies 4 in multiple groups of sub-board assemblies 4 pass through third connectors 11 It is electrically connected with the motherboard 3 and outputted through the first connector 9 of the motherboard 3 , and the other sub-board components 4 are electrically connected with the first connector 9 on the panel mounting frame 1 through wires 12 . Sufficient length is reserved for the wire 12, and the wire can be connected to the sub-board assembly 4 smoothly and conveniently after the sub-board assembly 4 is removed.

[0048] Since the motherboard 3 is a printed circuit board, its routing is fixed, so electrical components such as relays 8 that are determined to be used or not changed (general) are arranged on the sub-board assembly 4 connected to the motherboard 3, according to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com