Honeycomb-shaped heat radiator of LED lamp fitting

A technology of LED lamps and heat sinks, which is applied to the cooling/heating devices of lighting devices, lighting devices, components of lighting devices, etc. Heat dissipation effect, the effect of increasing the number of placements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

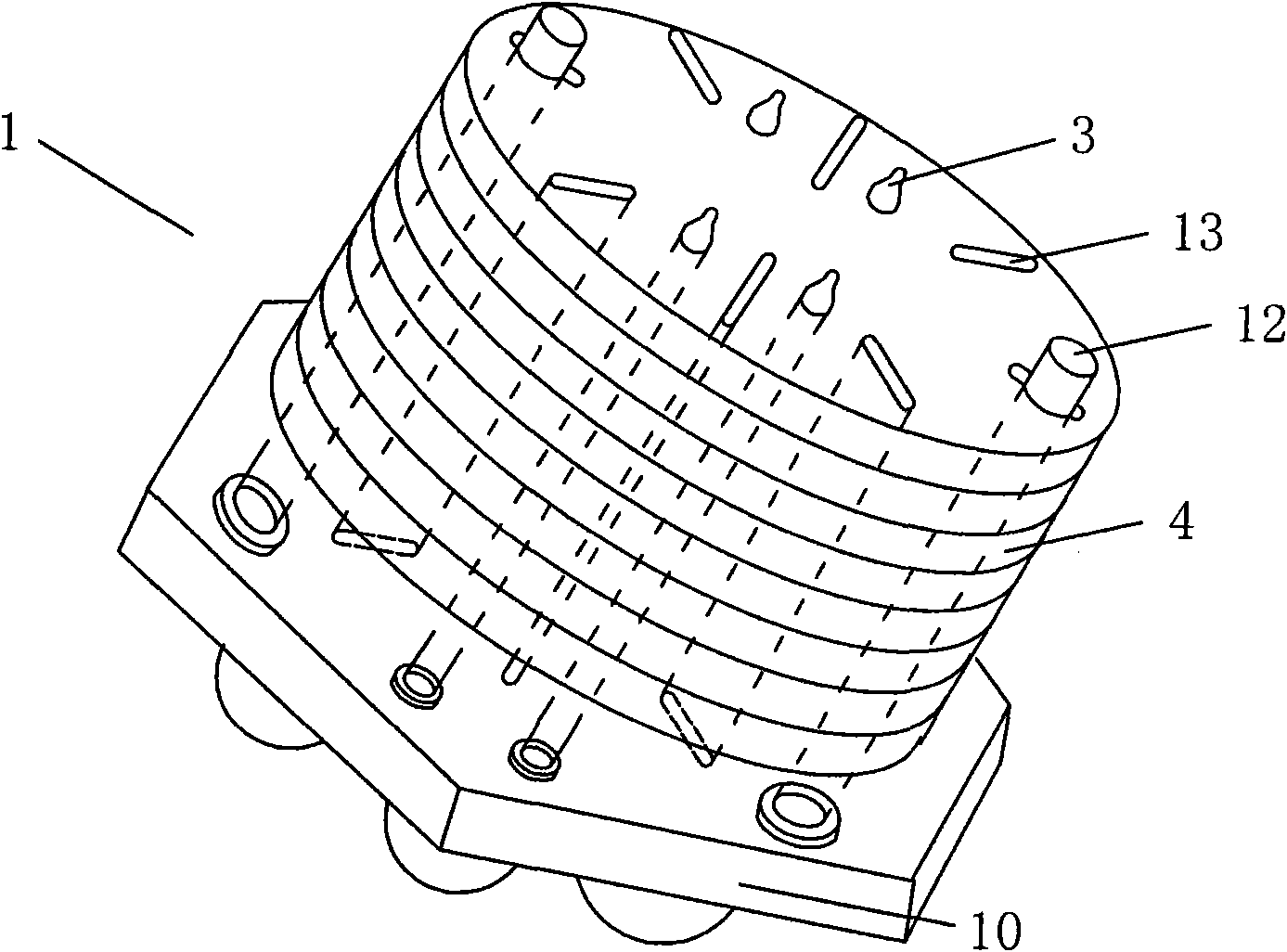

[0024] Such as Figure 1a and Figure 2a As shown, the LED lamp of the present invention includes a lampshade (not shown), an LED lighting device arranged in the lampshade, and a honeycomb heat sink 1 in contact with the LED lighting device, in order to prevent dust, insects, etc. from affecting the LED lighting device To extend the service life, the LED lighting device can be accommodated in the lampshade, which is usually made of transparent plastic, glass or other materials.

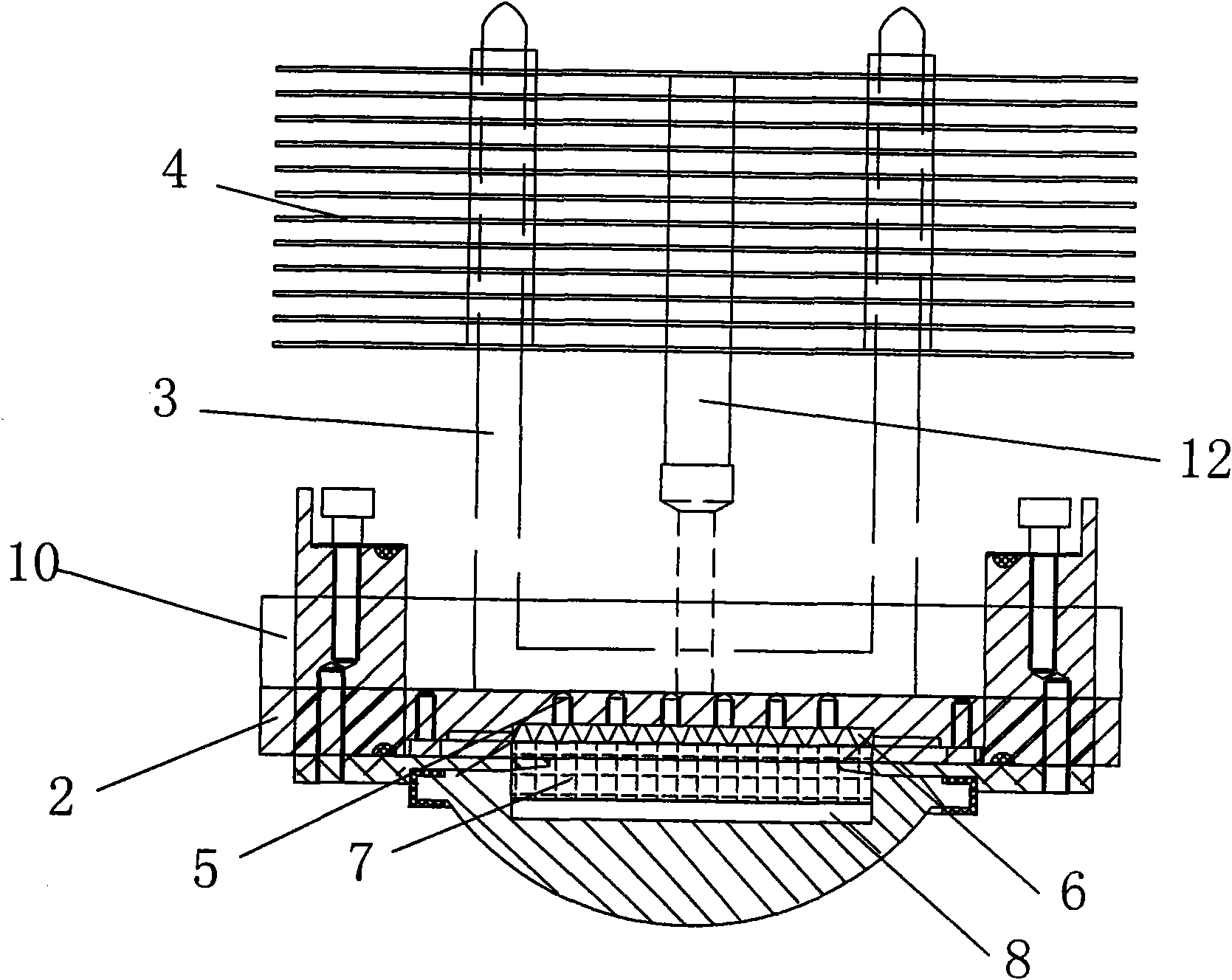

[0025] In the embodiment of the present invention, the honeycomb heat dissipation device 1 includes a ceramic substrate 2 sintered with a pure silver thermal conduction layer at the bottom, a heat dissipation pipe 3 at least partially in contact with the substrate, a heat dissipation fin 4 in contact with the heat dissipation pipe 3, and It also includes a mounting base 10 that is at least partially in contact with the substrate for fixing the heat dissipation pipe 3; the heat conduction layer 14 desc...

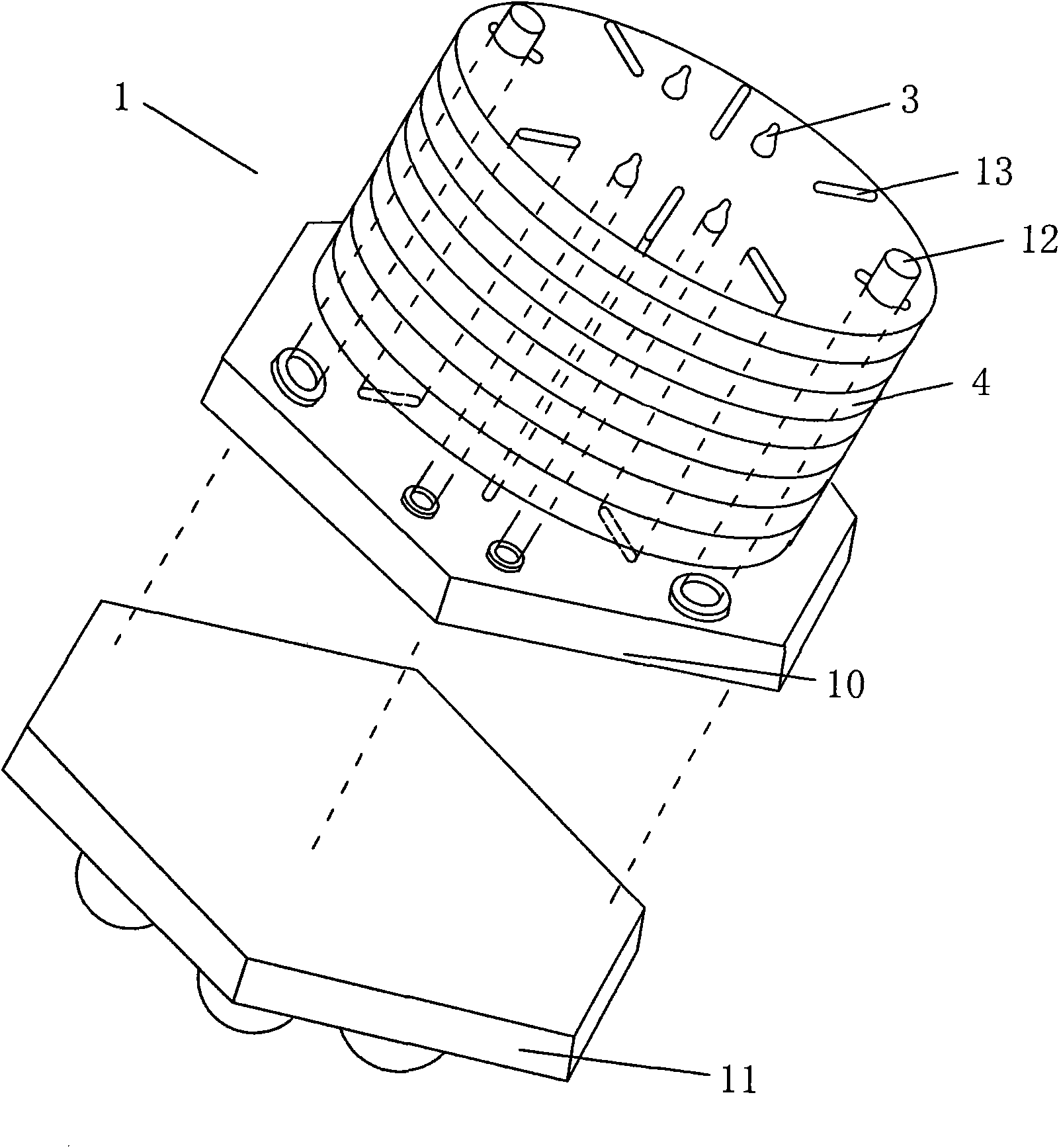

Embodiment 2

[0033] Such as Figure 1b and 2bAs shown, in the embodiment of the present invention, a copper mounting plate 11 is added between the mounting base 10 and the substrate, and the rest are the same as in Embodiment 1. The copper mounting plate 11 can be used to fix the LED lighting device or The uniformity of heat dissipation can be improved, and the heat can be evenly conducted to the honeycomb heat dissipation device 1 .

[0034] The heat dissipation method of the LED lamp of the present invention comprises the following steps:

[0035] S01. Transfer the heat of each LED light-emitting diode to the heat conduction layer through the heat conduction column, and then transfer the heat conduction layer to the heat dissipation pipe.

[0036] Specifically, the LED light-emitting diode transfers heat to the silver glue, and then the silver glue conducts to the heat-conducting column, and then the heat-conducting column transfers the heat to the heat-conducting layer, and finally th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com