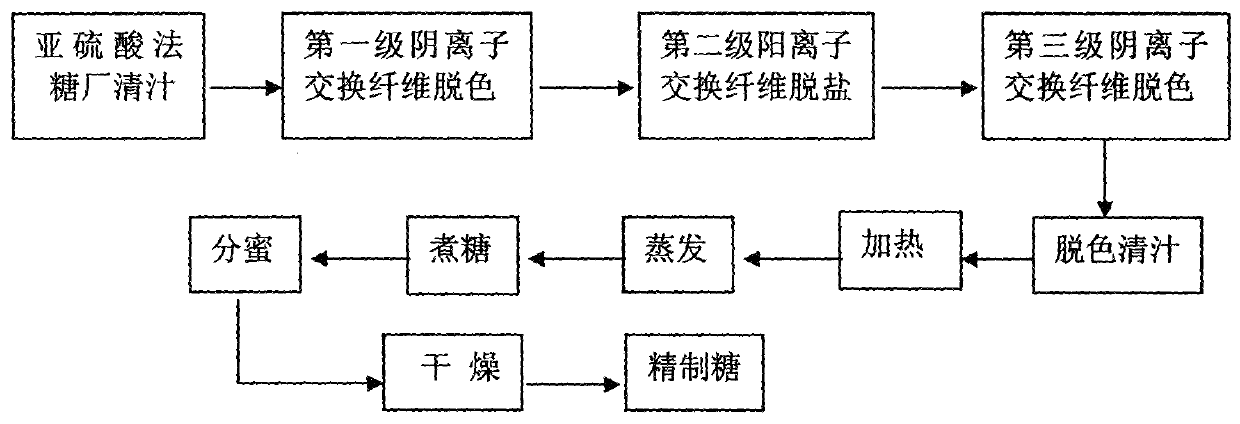

Method for producing refined sugar through ion-exchange fiber high efficiency decolorization one-step method

An ion-exchange fiber and fiber-exchange technology, which is applied in the field of high-efficiency decolorization of ion-exchange fibers to produce refined sugar by one-step method, can solve the problem that the ion-exchange resin method cannot meet the requirements of clear juice in cane sugar factories, is rarely used in sugar factories, and has a slow adsorption and exchange rate. and other problems, to achieve the effect of saving the secondary evaporation crystallization process, ensuring the thoroughness of regeneration, and saving energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

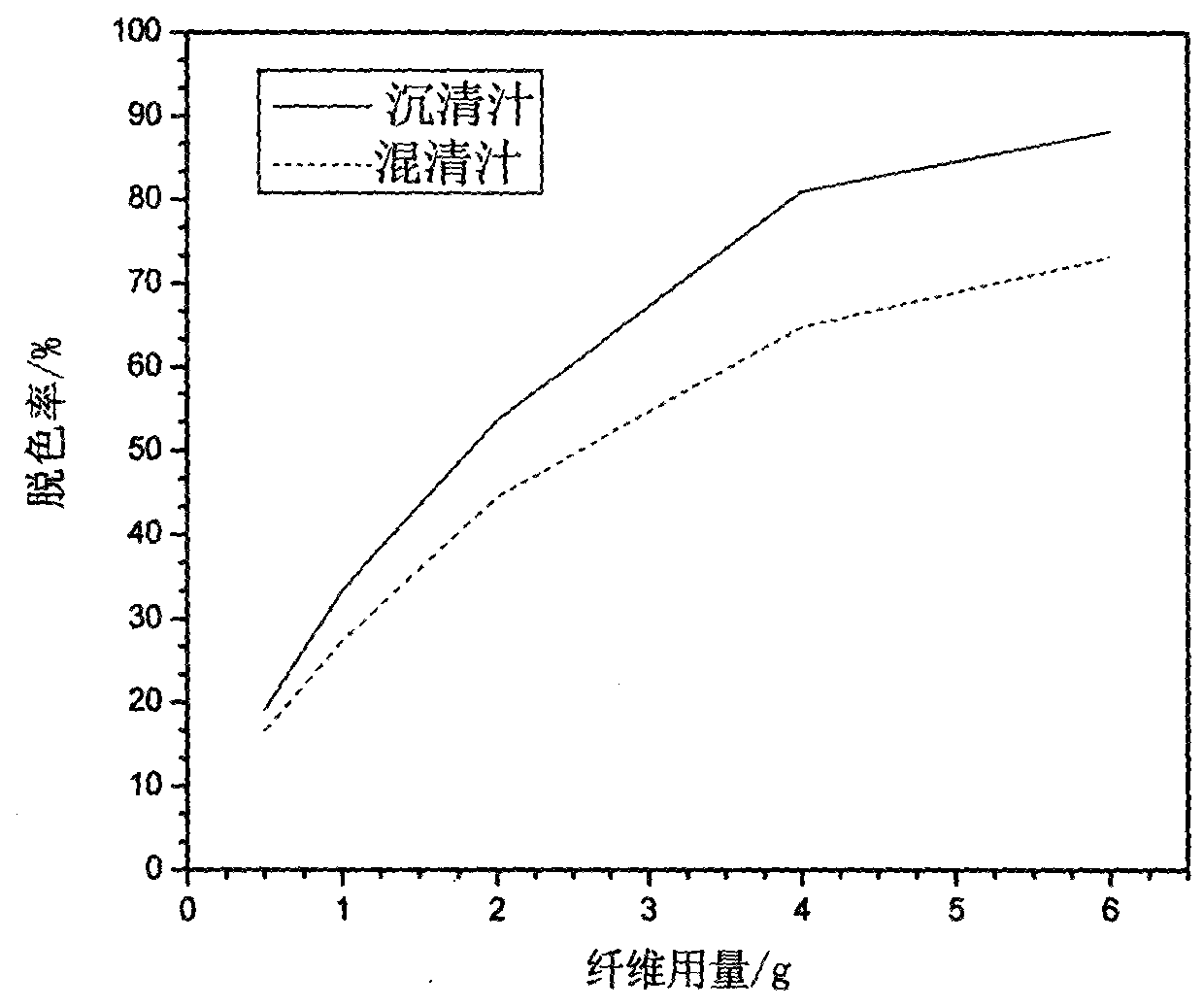

[0079] Decolorization Test of Ion Exchange Fiber on Yaffa Juice

[0080] The test selects the clean juice and clarified juice of the sulfite sugar factory to carry out the static decolorization comparison test. The test results are shown in figure 2 . From figure 2 It can be seen that the decolorization rate of ion exchange fiber to clarified juice is significantly higher than that of clean juice. Clean juice is mixed with clarified juice and filtered juice. Clean juice contains more suspended matter than clarified juice, and suspended matter is easy to cover on the fiber. The surface of the surface, while the ion exchange process is carried out on the surface, the suspended matter prevents the ion exchange and adsorption decolorization process, so that the decolorization efficiency of the clarified juice is reduced. Therefore, the use of ion exchange fibers to decolorize sugar juice should try to avoid the pollution of suspended solids, especially colloids.

Embodiment 2

[0082] Decolorization Test of Ion Exchange Fiber on Sugar Juice by Carbon Method

[0083] The comparison test of the decolorization effect of anion exchange fiber on various sugar juices by carbon method, the results are shown in Table 1.

[0084] Table 1

[0085]

[0086] The test results show that the decolorization effect on Erqing juice is obvious, and the treatment capacity is large.

Embodiment 3

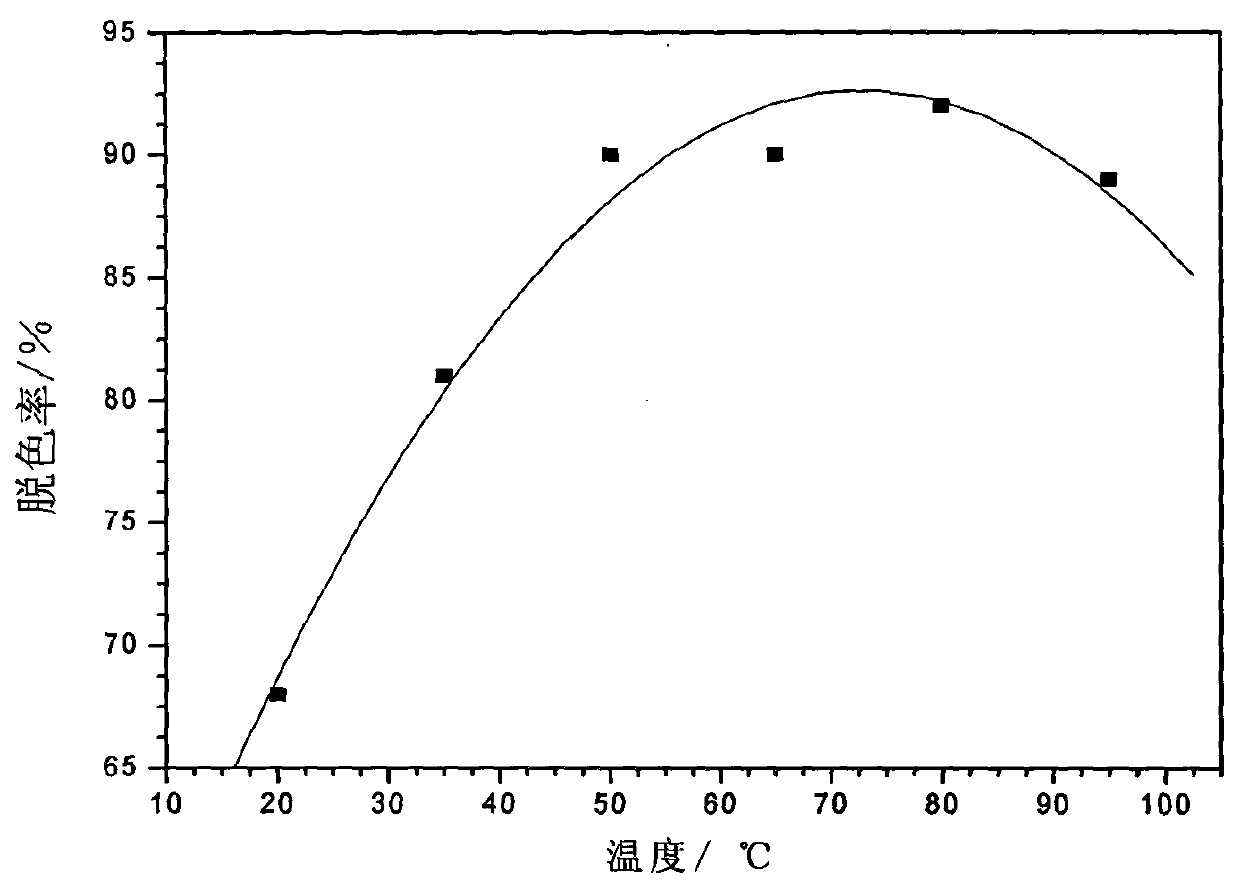

[0088] Effect of Temperature on Decolorization Efficiency of Erqing Juice

[0089] Take 20g of fiber (wet), adjust the temperature of the clear juice by cooling or heating, and measure its color value after reacting for 30 minutes. The results are shown in image 3 .

[0090] From image 3 It can be seen that the optimum temperature range for decolorization of sugar juice by ion exchange fibers is between 65 and 80°C, and above 80°C, the decolorization rate decreases slightly with the increase of temperature, which is because the decolorization process belongs to adsorption. The exchange process belongs to chemical adsorption. The active point on the surface of the ion exchange fiber is chemically combined with the solute, resulting in electron transfer phenomenon. The adsorption exchange process is mainly an exothermic reaction. The temperature has a certain influence on the exchange process, and it is stronger when the temperature is low. It is weaker when the temperature ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com