Equipment production flow using flash memory as storage medium

A storage medium and production process technology, applied in static memory, electrical program control, comprehensive factory control, etc., can solve the problems of increased read and write workload, long time spent, increased time cost, etc., and achieve large-scale batch production The effect of production, improving production efficiency, and increasing production quantity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

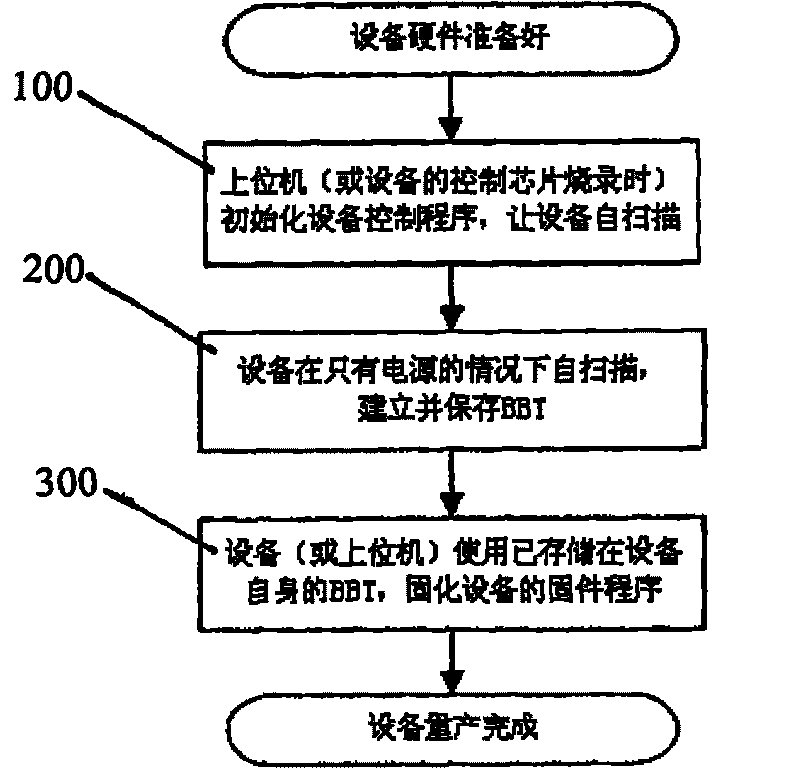

[0015] The specific method of the present invention will be described in detail below in conjunction with the accompanying drawings.

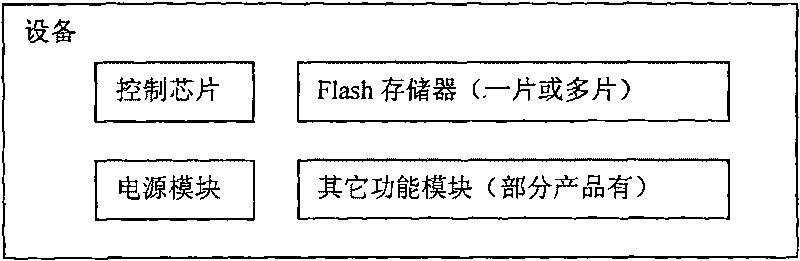

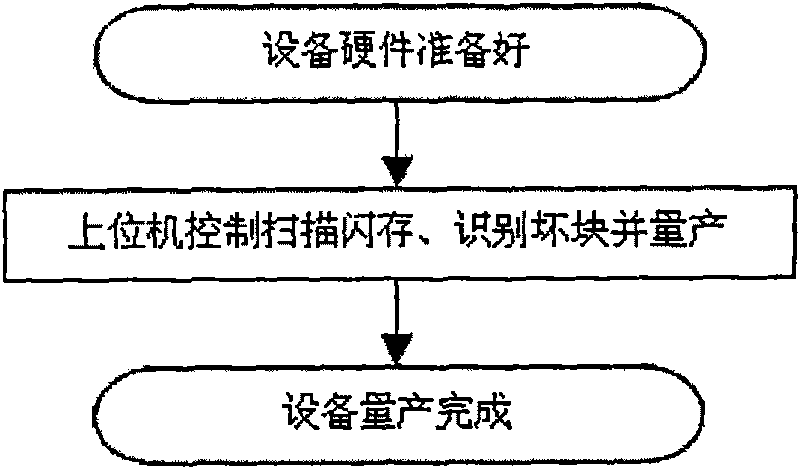

[0016] The lower computer production (i.e. production method) of the present invention only refers to scanning the flash memory in the lower computer and solidifying the firmware program, and does not include physical assembly.

[0017] The focus of the present invention is to improve the production mode under the traditional technology, and change the traditional mode of scanning the flash memory of the lower computer from the empty machine of the upper computer to the self-scanning method of the lower computer. That is to say, after the lower computer is separated from the upper computer, it can scan by its own control chip under the condition of only power supply.

[0018] In the present invention, the concept of bad block table BBT is introduced, which refers to the collection of records of good and bad conditions of each "block" in the fla...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com