Auxiliary mechanism for automatically adjusting gap between vibration tables for clay sand horizontal molding machine

An automatic adjustment and auxiliary mechanism technology, applied in the direction of molding machines, molding tables, casting and molding equipment, etc., can solve the problems of increased labor intensity of the operator, weak vibration, and difficulty in the operator's proficiency, so as to improve the vibration effect, Improving production efficiency and avoiding the separation between the shock table and the piston

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described below in conjunction with accompanying drawing:

[0024] as attached figure 1 to attach Figure 5 Shown:

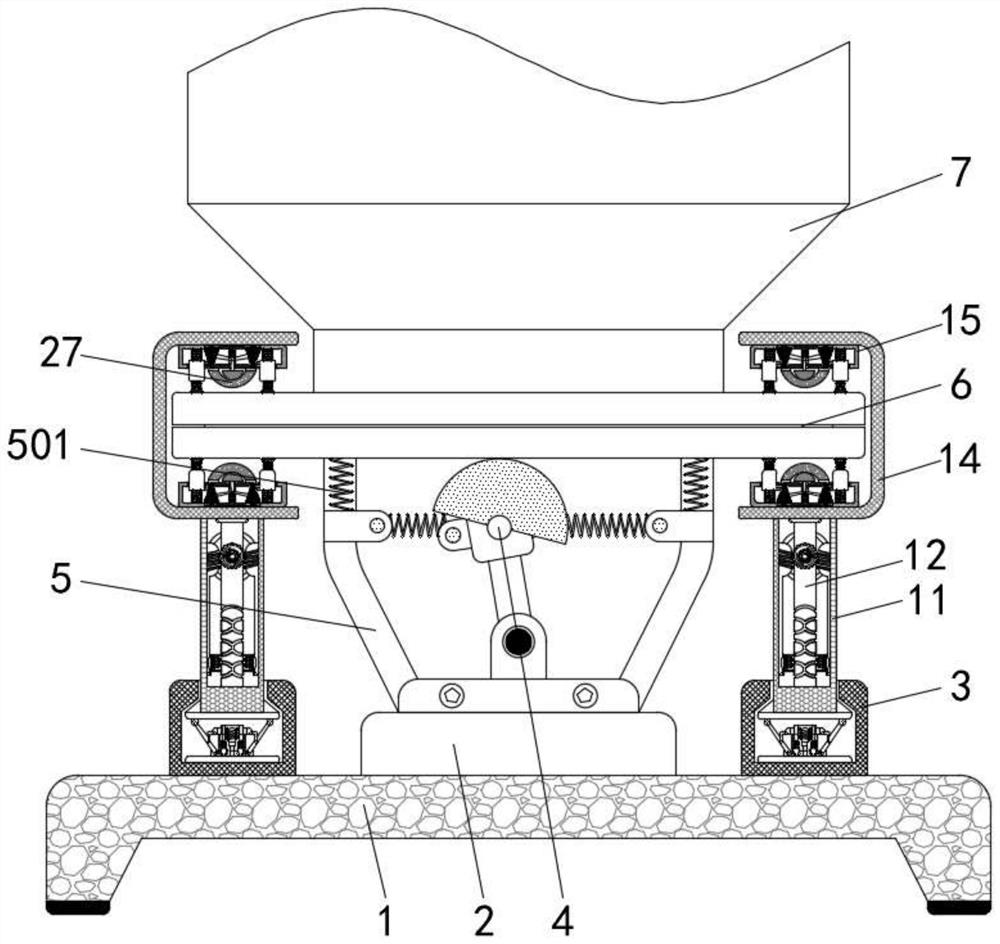

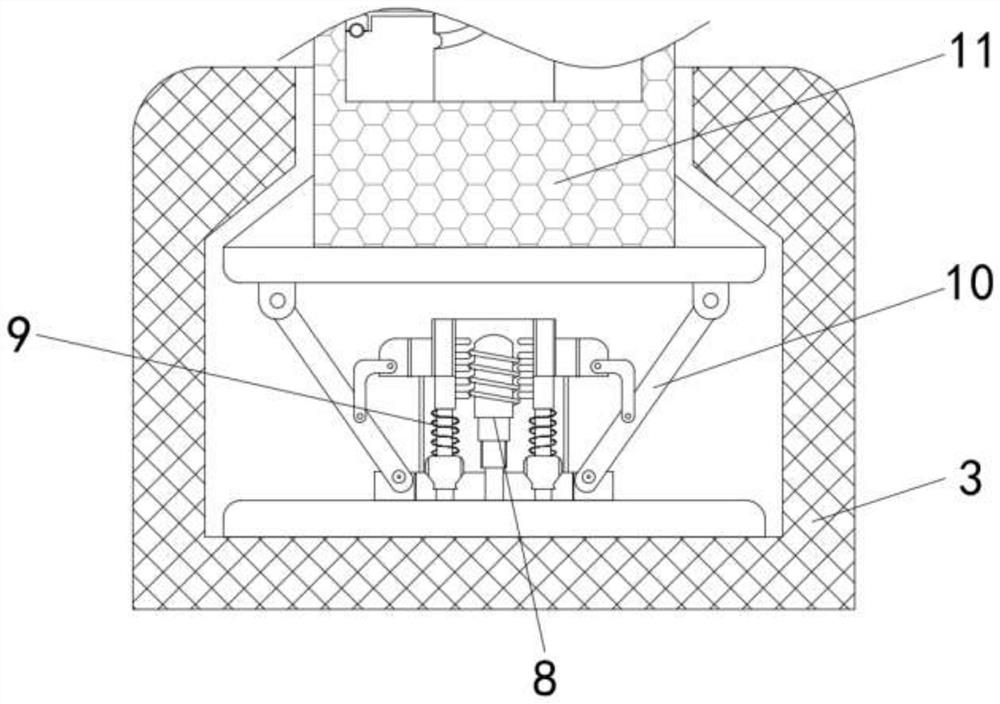

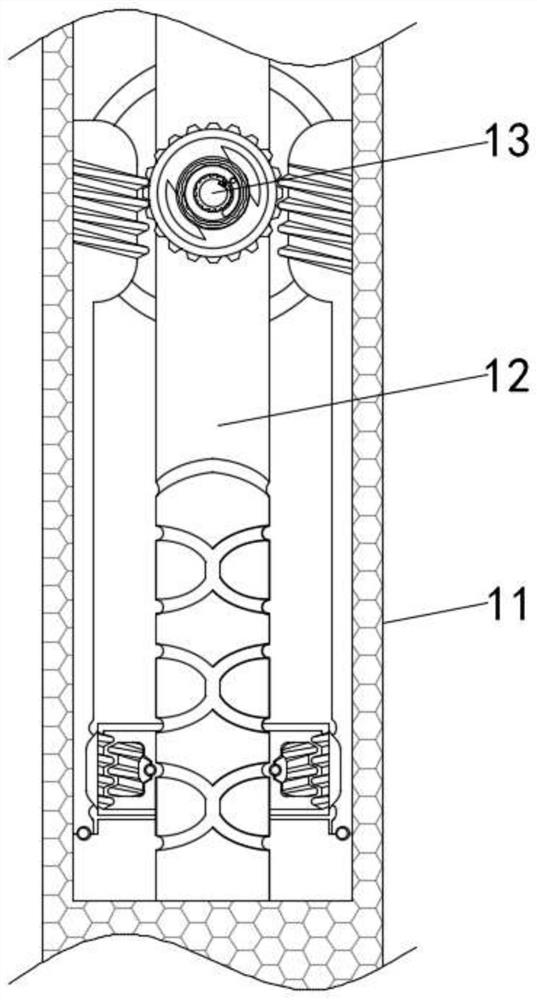

[0025] The invention provides an auxiliary mechanism for automatically adjusting the gap between shock tables for a clay sand horizontal molding machine. There are vibrating mechanism 4 and vibrating support 5, the upper side of vibrating mechanism 4 is provided with installing shock table 6, and vibrating spring 501 is installed between vibrating mechanism 4 and vibrating support 5, and the upper end of vibrating spring 501 is installed with vibrating platform 6 phase Connection, using the vibration spring 501 on the vibration bracket 5 to move synchronously, and then keep shaking, thereby effectively improving the vibration effect of the equipment shell 7, installing the vibration platform 6 to form the connection between the vibration platform and the piston, through the continuous operation of the equipment, Du...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com