Green sand box molding machine

A molding machine and green sand technology, which is applied in the field of automatic green sand molding machines with boxes, to achieve the effects of low noise pollution, smooth surface and improved work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] The preferred embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

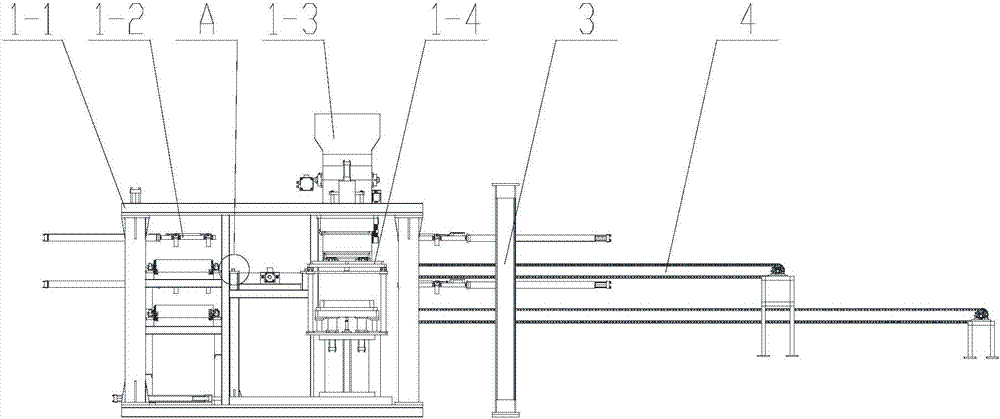

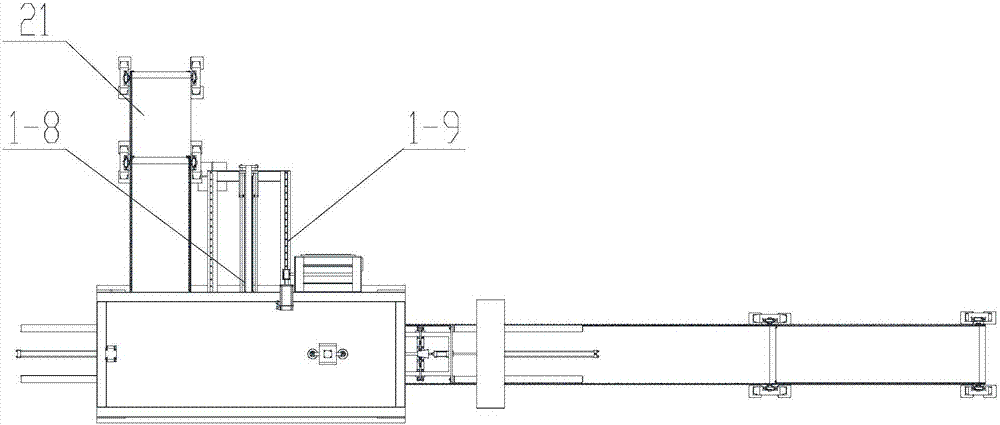

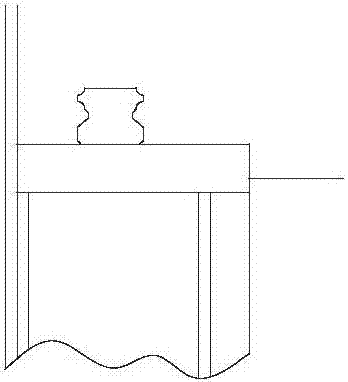

[0041] In this embodiment, there is a box molding machine ( Figure 1-4 ) includes molding machine frame 1-1, unpacking conveyor chain 21, molding machine box-in box manipulator 2, sand shooting machine 1-3, molding machine workbench 1-4, molding machine box-out manipulator 3, box-closing conveyor chain 4, etc. The case-in side of the case-in molding machine is vertically connected to the unpacking conveyor chain 21, and its side is also vertically connected to the template quick-change mechanism and the sand-shooting machine 1-3, and the case-in molding machine is equipped with a molding machine workbench 1-4, The box-in side of the box molding machine is equipped with a molding machine box-in manipulator 2, and its opposite side, that is, the box-out side, is equipped with a molding machine out-of-box manipulator 3, and the box-out side...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com