Modeling platform for automobile casting

A platform and casting technology, which is applied in the field of molding platforms for automotive castings, can solve the problems of increased production costs, occupied space, and many types of workbenches, and achieves the effects of low cost, reduced floor space, and good economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The preferred embodiments of the present invention will be described in detail below with reference to the accompanying drawings.

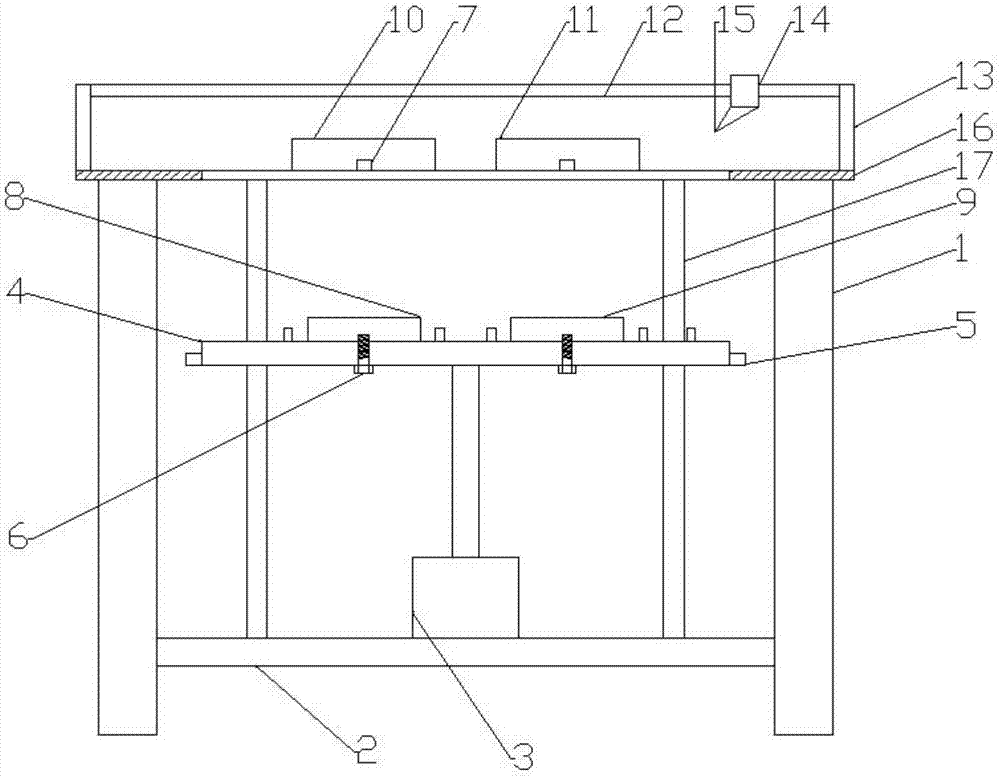

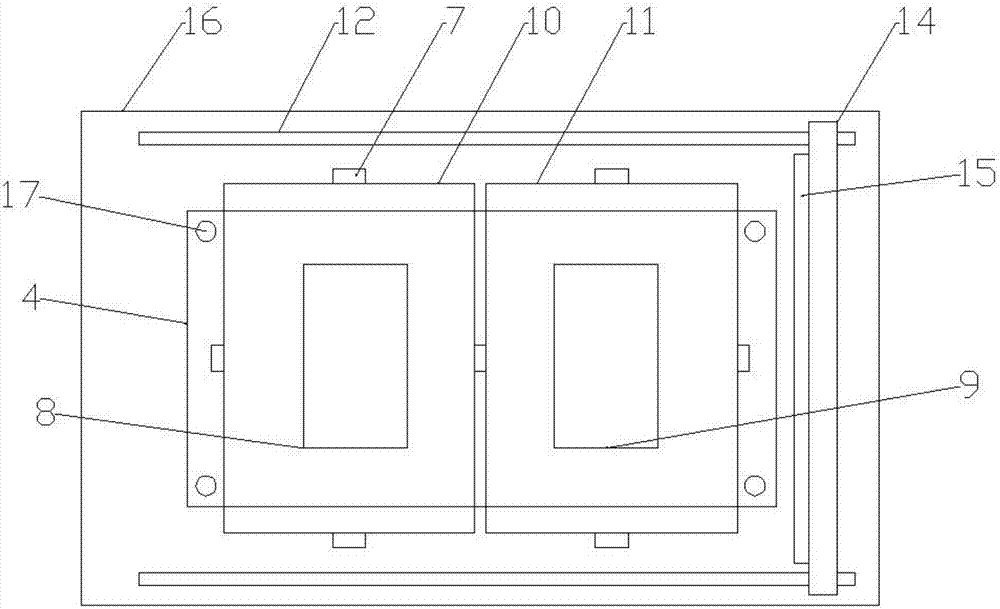

[0015] Figure 1-2 A specific embodiment of the present invention is shown: a modeling platform for automobile castings, comprising a foot 1, a supporting plate 2 is provided on the supporting foot 1, and a linear drive device 3 is provided on the supporting plate 2, and the linear drive device 3 is provided with a platform 4 at the upper end, the support plate 2 is also provided with four guide posts 17 which are slidably connected to the platform 4, and the two ends of the platform 4 are provided with limit blocks 5, the An upper model 8 and a lower model 9 are provided on the platform one. Both the upper model 8 and the lower model 9 are fixed on the platform one 4 by fixing bolts 6. The upper end of the supporting foot 1 is provided with a platform two 16 and the platform two 16 is provided with an upper sand box 10 and a lower sand box 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com