Sand coating mold module for casting and sand coating casting technique

A casting section and mold technology, applied in the direction of casting mold, casting mold composition, manufacturing tools, etc., can solve the problems that the casting section cannot open the international market, the product cannot meet its requirements, and the appearance requirements of the casting section are very strict, etc. Defect problem, dense organization, consistent effect of upper and lower caliber

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

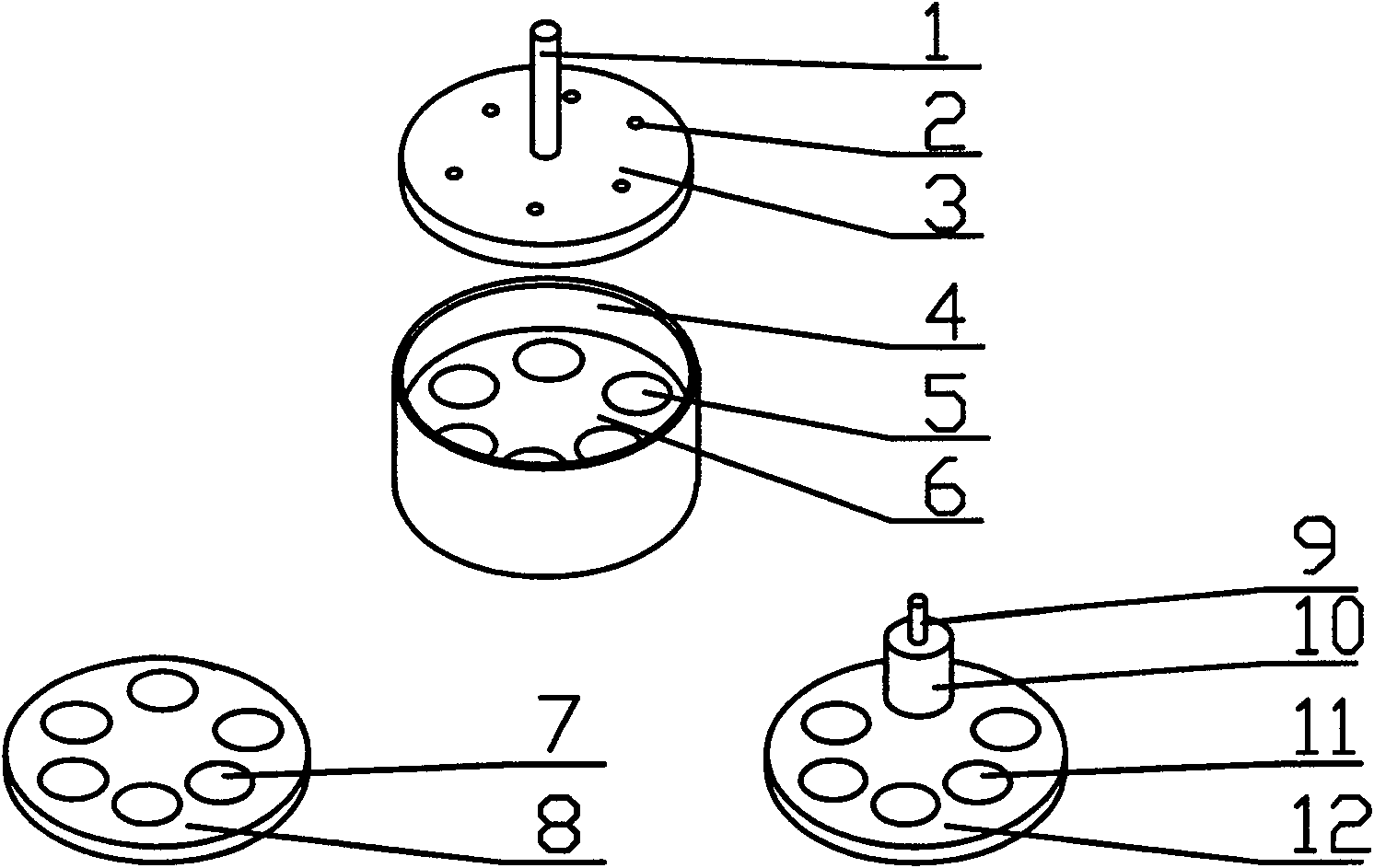

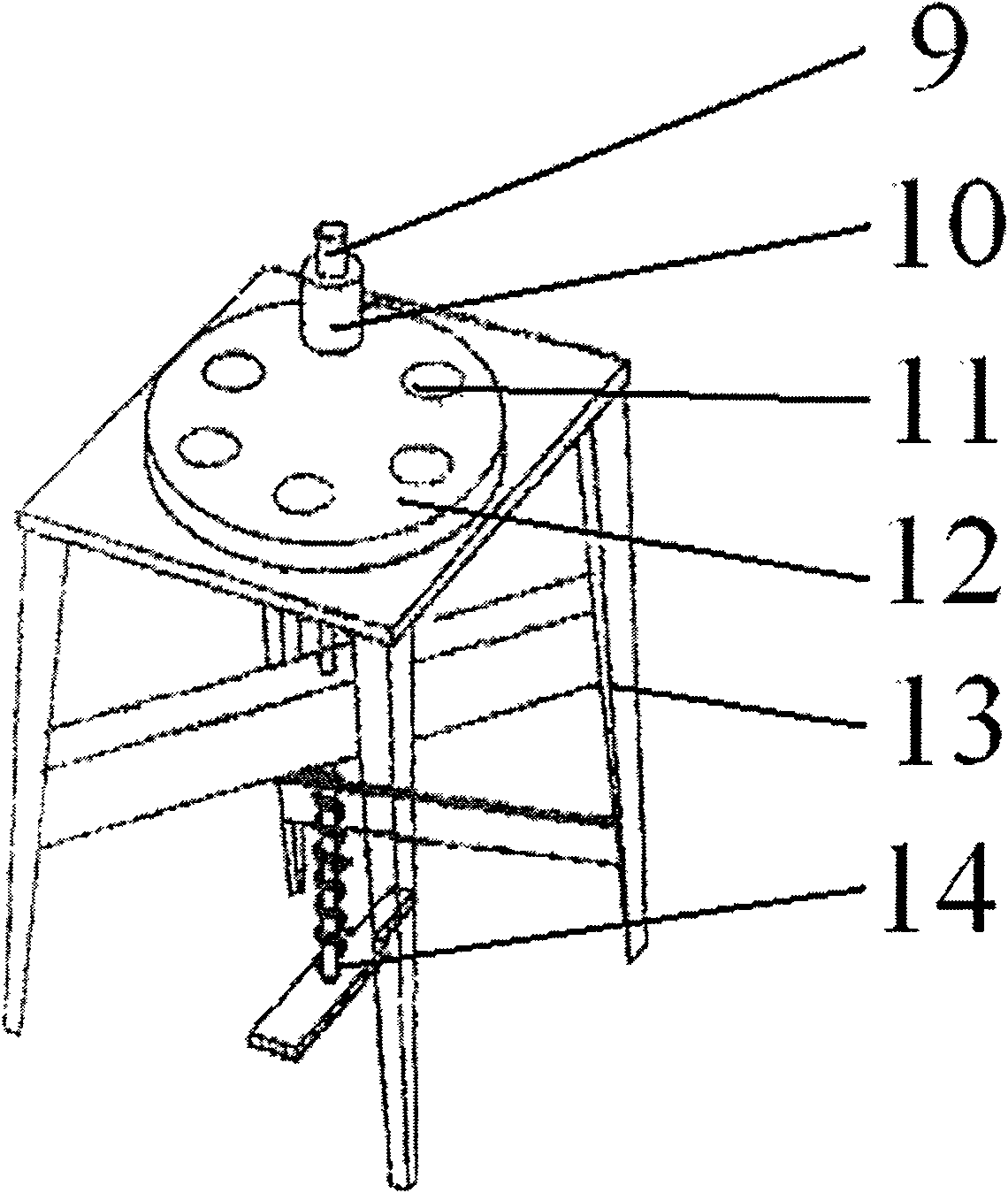

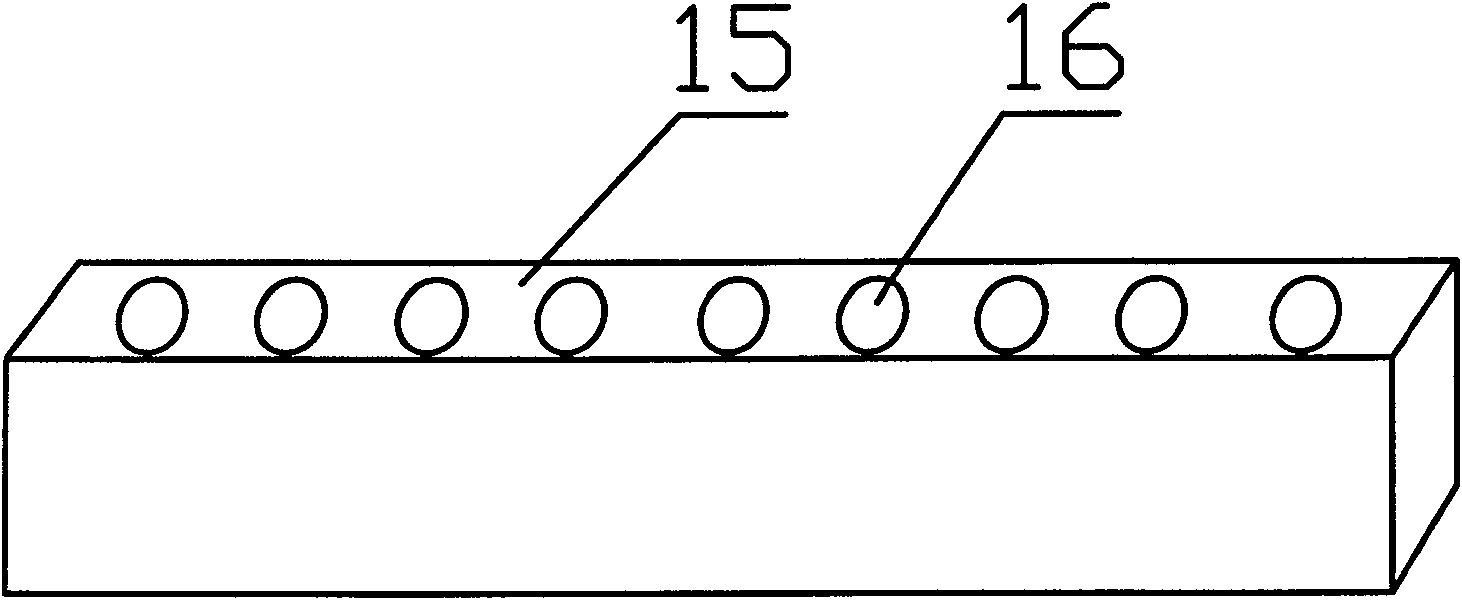

[0023] Such as figure 1 As shown, the sand-hanging mold assembly of the casting section of the present invention is composed of five parts, including a mold main body 4, a mold bottom 8, a mold cover 3, a mold plate 12, and a casting section mold core. The mold main body 4 is a cylindrical iron mold with a recessed platform 6 at one end, and six axially penetrating circular mold holes 5 are arranged in the cylindrical iron mold. The mold bottom 8 is a circular iron plate of the same size, and the mold bottom 8 is provided with six circular recesses 7 at positions corresponding to the circular mold holes 5 of the mold main body 4. The molding disc 12 is a circular disc as large as the bottom of the mold, and the position on the disc corresponding to the recess is a through hole 11. The casting section mold core is composed of a large mold core 10 and a small mold core 9. The large mold core 10 is also a cylindrical steel core with a diameter smaller than the circular mold hole 5, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com