Servo control high-speed multi-station core making machine

A servo-controlled, multi-station technology, applied in the direction of manufacturing tools, cores, molding machines, etc., can solve the problems of fewer molds installed in the core making machine and low production efficiency, and achieve high core-making efficiency, improved production efficiency, and improved The effect of market competitiveness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

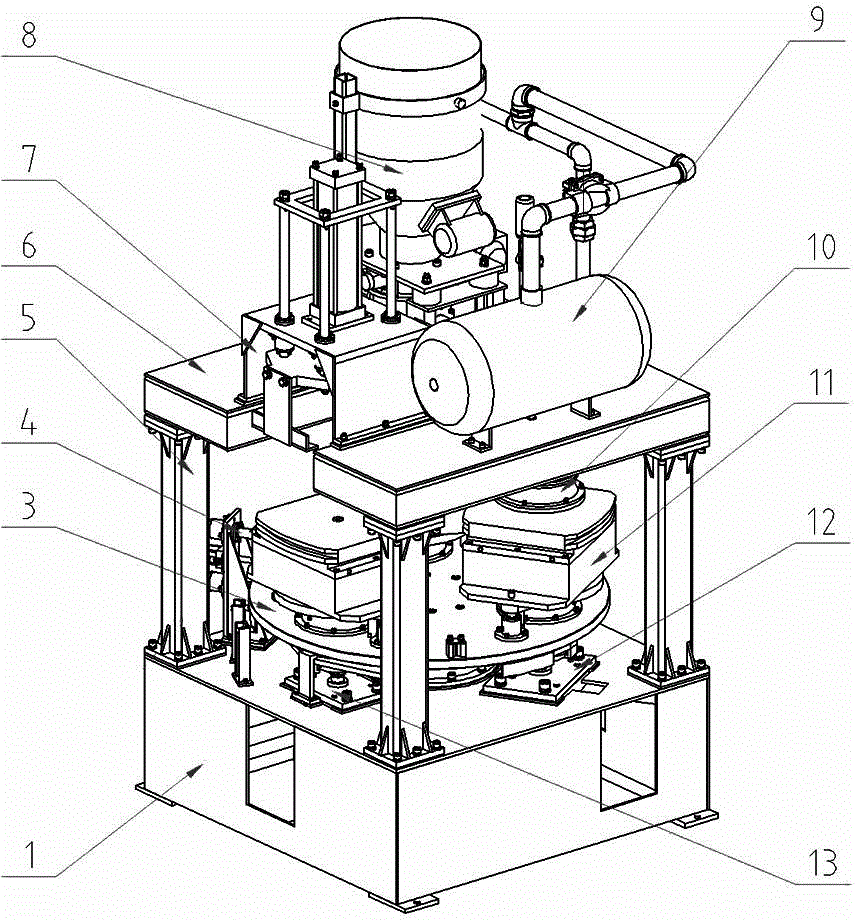

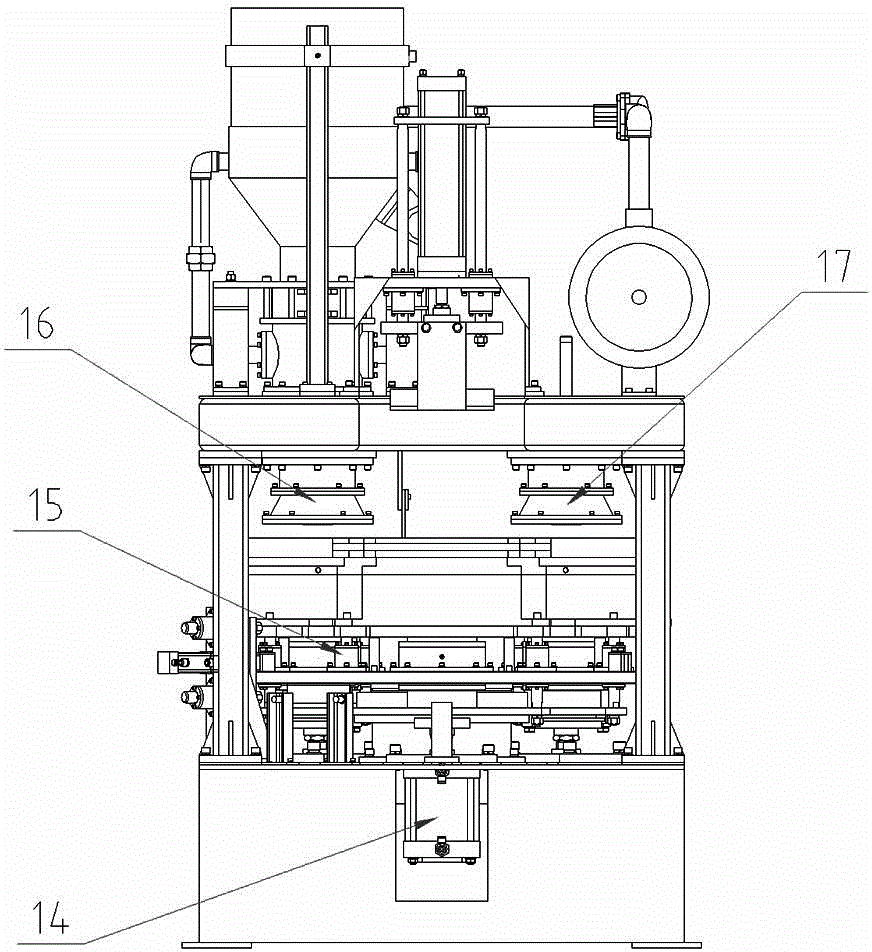

[0023] Such as figure 1 As shown, the present invention includes a base 1, a column 5, a rotary table 3, a servo motor drive device, a mold lifting mechanism, a lower core mechanism, an auxiliary positioning mechanism, an upper beam frame 6, an upper mold opening mechanism 7, and a sand shooting mechanism , Blowing agencies and other auxiliary agencies.

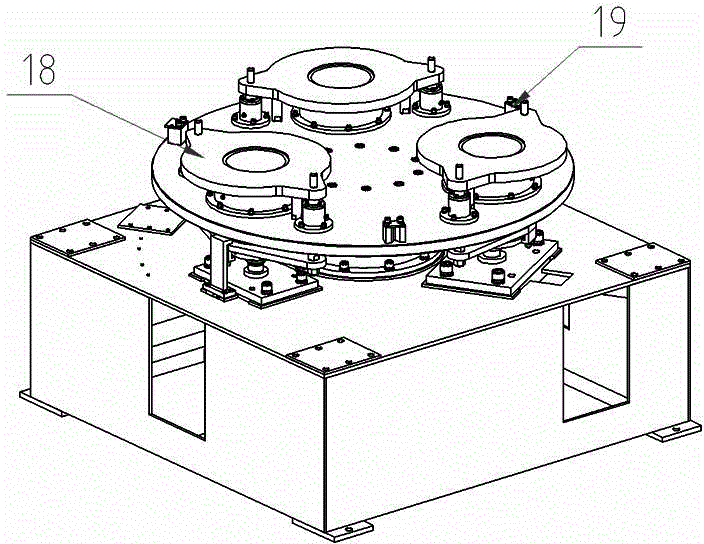

[0024] The base 1 is a rectangular frame made of steel plates, section steel, etc., and the base 1 is provided with a lower core cylinder 13, a core box first lift cylinder, a core box lift cylinder 12 and corresponding position control devices. In the middle part of the base 1 is provided with a rotary support mechanism 14 ( figure 2 ), used to support the rotating shaft connected to the bottom of the rotary table 3 . The rotary table 3 is supported by a rotary support mechanism and driven by a servo motor to control the rotation angle and stop position, so as to complete the action cycle of the core box in the three stat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com