Gold alloy, method for manufacturing spring using gold alloy and the prepared spring

A gold alloy and alloy technology, applied in the field of springs, can solve the problems of inability to contain gold in the spring matrix, difficult performance requirements, etc., and achieve the effect of excellent fatigue resistance and processing performance, and high yield strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

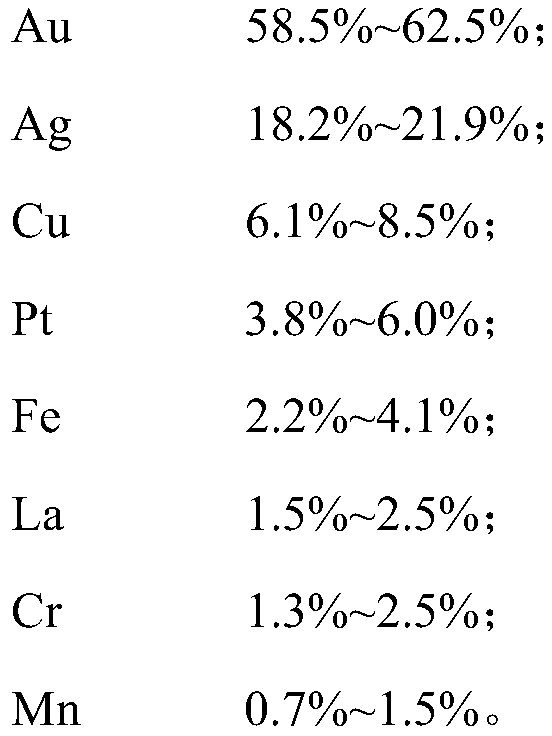

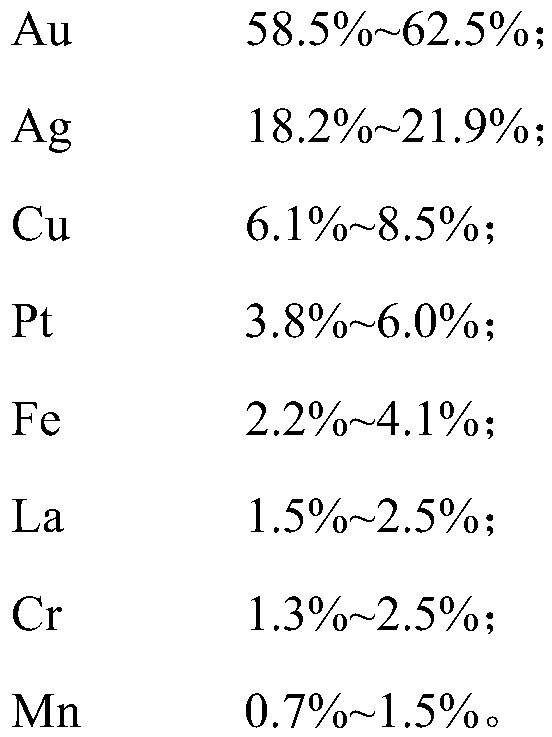

Method used

Image

Examples

Embodiment 1

[0041] Adopt following steps to prepare gold alloy spring according to the present invention:

[0042] (1) Heat 6.0g of Au, 2.0g of Ag, 0.7g of Cu, 0.5g of Pt, 0.3g of Fe, 0.2g of La, 0.2g of Cr and 0.1g of Mn to about 1300°C and keep it warm After 25 minutes, cast into an ingot bar with a cross-sectional side length of 10mm×10mm;

[0043] (2) rolling the ingot bar into a metal wire and performing the following annealing treatment: (a) rolling the ingot bar into a metal round bar with a diameter of 7 mm, and then holding it at a temperature of 850° C. for 4 minutes, Cool naturally to room temperature for annealing; (b) Roll the annealed metal round bar in step (a) into a metal rod with a diameter of 4mm, then keep it at a temperature of 840°C for 5 minutes, and cool naturally to room temperature for annealing (c) rolling the annealed metal rod into a metal wire with a diameter of 2mm in step (b), then keeping it at a temperature of 860° C. for 5 minutes, and cooling naturally...

Embodiment 2

[0048] Adopt following steps to prepare gold alloy spring according to the present invention:

[0049] (1) Heat 6.19g of Au, 1.82g of Ag, 0.80g of Cu, 0.38g of Pt, 0.37g of Fe, 0.15g of La, 0.22g of Cr and 0.07g of Mn to about 1250°C and keep it warm After 30 minutes, cast into an ingot bar with a cross-sectional side length of 10mm × 10mm;

[0050] (2) Rolling the ingot bar into a metal wire and performing the following annealing treatment: (a) rolling the ingot bar into a metal round bar with a diameter of 7.5 mm, and then holding it at a temperature of 840° C. for 4 minutes , naturally cooled to room temperature for annealing; (b) rolling the annealed metal round bar in step (a) into a metal rod with a diameter of 4.5mm, then keeping it at a temperature of 840°C for 5 minutes, and cooling naturally to room temperature or less Annealing; (c) rolling the annealed metal rod into a metal wire with a diameter of 2mm in step (b), then keeping it at a temperature of 850° C. for 5...

Embodiment 3

[0055] Adopt following steps to prepare gold alloy spring according to the present invention:

[0056] (1) Heat 6.08g of Au, 2.07g of Ag, 0.61g of Cu, 0.55g of Pt, 0.22g of Fe, 0.22g of La, 0.13g of Cr and 0.12g of Mn to about 1350°C and keep it warm After 30 minutes, cast into an ingot bar with a cross-sectional side length of 10mm × 10mm;

[0057] (2) rolling the ingot bar into a metal wire and performing the following annealing treatment: (a) rolling the ingot bar into a metal round bar with a diameter of 8 mm, and then holding it at a temperature of 860° C. for 6 minutes, Cool naturally to room temperature for annealing; (b) Roll the annealed metal round bar in step (a) into a metal rod with a diameter of 4 mm, then keep it at a temperature of 860 ° C for 5 minutes, and cool naturally to room temperature for annealing (c) rolling the annealed metal rod into a metal wire with a diameter of 2.5mm in step (b), then keeping it at a temperature of 870° C. for 4 minutes, and co...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com