Aluminum alloy and preparation method thereof

A technology for aluminum alloys and aluminum ingots, applied in the field of aluminum alloys, can solve problems such as poor softness and flexibility, use restrictions, unstable cupping phenomenon, etc., and achieve the effects of uniform crystallization, softness, and elongation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

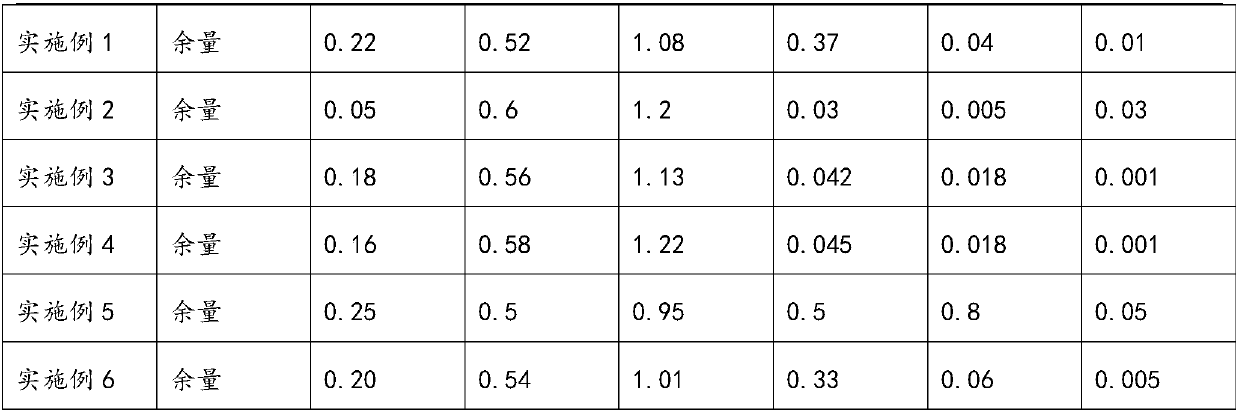

[0049] This embodiment discloses a method for preparing an aluminum alloy, comprising the following steps:

[0050] A. Melting

[0051] Melting Al, Si, Fe,, Mn, and Cu according to the mass fraction;

[0052] The melting temperature is 726°C;

[0053] Let stand for 10 minutes; then,

[0054] Stir, add Mg and Ti, mix well;

[0055] Refining degassing with nitrogen;

[0056] B. Deep well casting

[0057] Temperature 715°C;

[0058] Casting speed 90mm / min;

[0059] Adjust the frequency of the water pump to 28 Hz;

[0060] C. Hot rolling

[0061] Homogenization of cast aluminum ingots prior to hot rolling. The crystallization inside the aluminum ingot is uniformly adjusted by heating for a long time to ensure that the cast aluminum ingot is suitable for hot rolling.

[0062] The technological conditions of the homogenization treatment are: temperature 600° C., holding time 10 hours. The heat preservation temperature and heat preservation time of this homogeneous treatme...

Embodiment 2

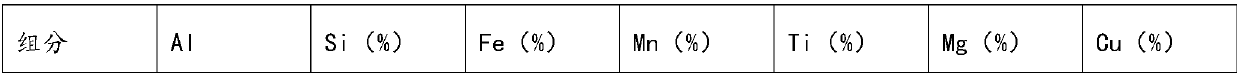

[0078] The main difference between this embodiment and Example 1 lies in the mass fraction of the alloy components and the process parameters of each step; the mass fraction of each component of the alloy in this embodiment is shown in Table 1, and the process parameters of each step in this embodiment are detailed in Table 2, the evaluation indexes of the aluminum plate prepared in this embodiment are shown in Table 3.

Embodiment 3

[0080] The main difference between this embodiment and Example 1 lies in the mass fraction of the alloy components and the process parameters of each step; the mass fraction of each component of the alloy in this embodiment is shown in Table 1, and the process parameters of each step in this embodiment are detailed in Table 2, the evaluation indexes of the aluminum plate prepared in this embodiment are shown in Table 3.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| surface smoothness | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com