High fluorine-containing aromatic-aliphatic negative photoresist and application thereof to preparing polymer waveguide devices

A technology of negative photoresist and waveguide devices, which is applied in the directions of photosensitive materials, light guides, and optical components used in opto-mechanical equipment, and can solve the problems of large light loss and so on.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

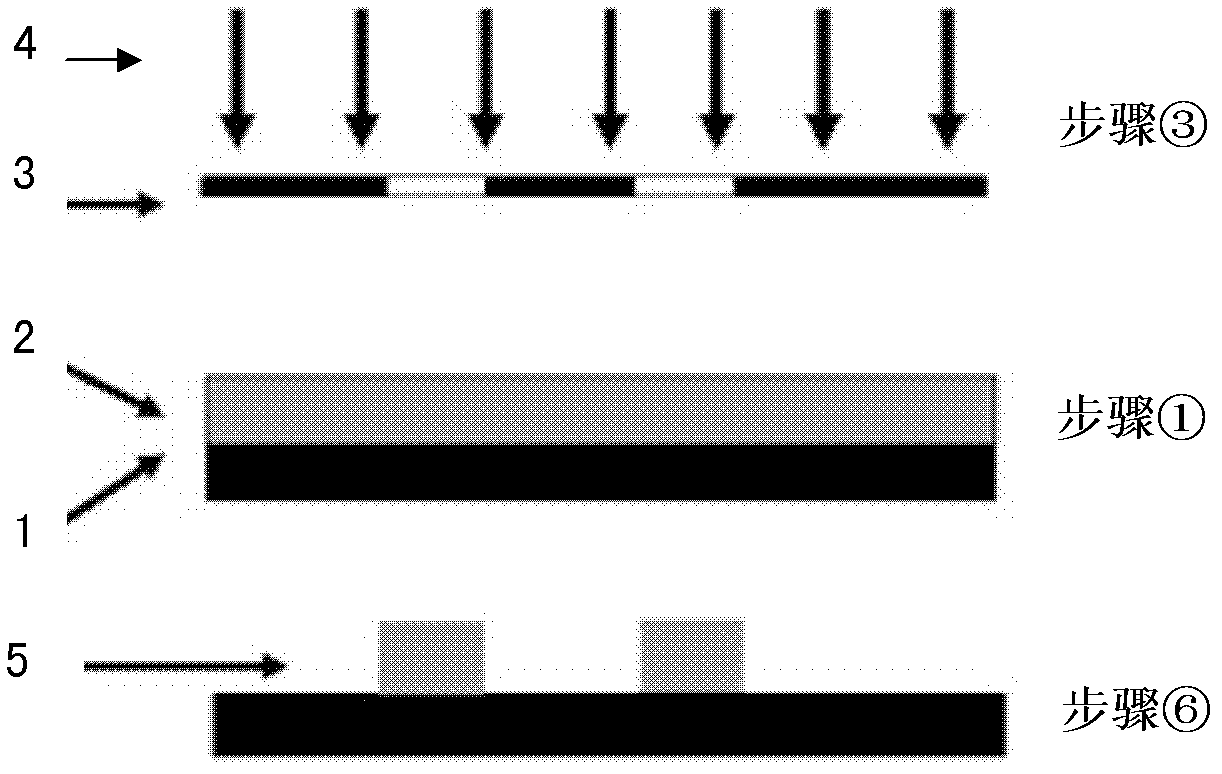

Method used

Image

Examples

Embodiment 1

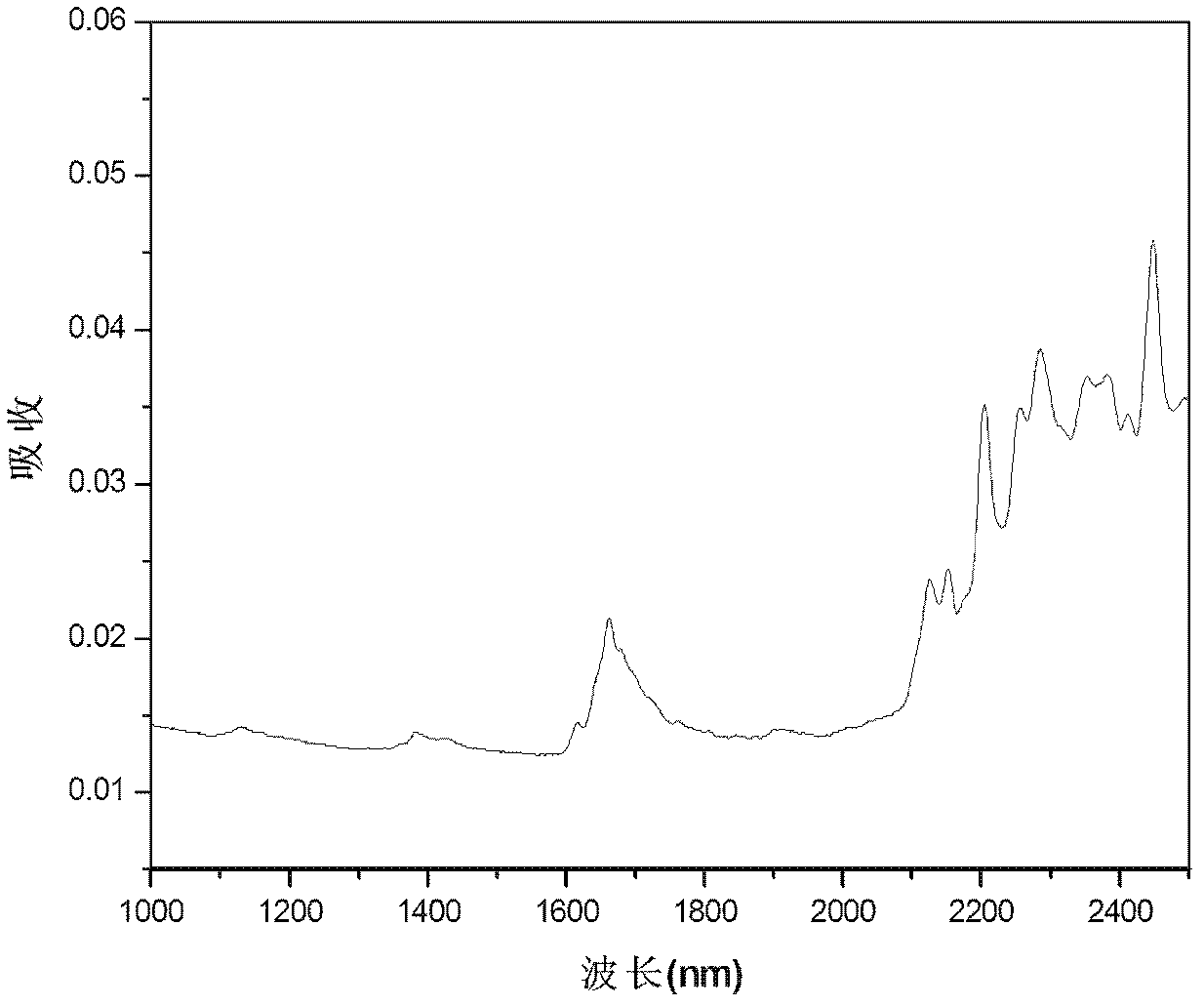

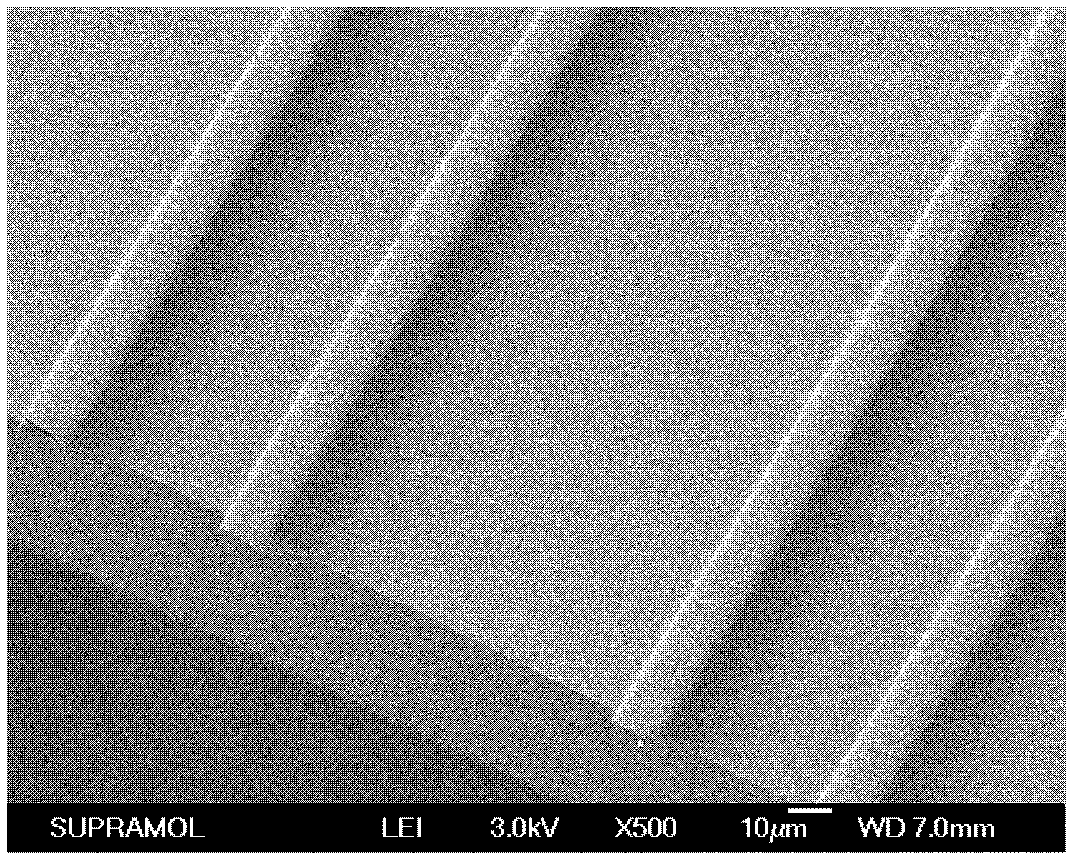

[0028] Dissolve 1.40g 3-methoxy 1,4-hydroquinone, 6.68g decafluorobiphenyl, 1.04g 1,5-pentanediol in 50ml N,N-dimethylacetamide, add the catalyst cesium fluoride 4g, the mixture was heated to 60°C, and reacted at this temperature for 18h. The reactant was precipitated in a large amount of methanol, washed with water several times, and dried to obtain a white solid. The upper product was dissolved in 30 mL of dichloromethane, and the reaction temperature was kept at about 0°C during the ice bath reaction. Then slowly drip in containing BBr 3 CH 2 Cl 2 的 solution 5mL, of which BBr 3 The content is 6.06mmol. After the addition is complete, react at room temperature for 24 hours. The reactant was precipitated in methanol, washed with water several times, and dried to obtain a white solid product. The upper reaction product was dissolved in 20 mL of epichlorohydrin, the temperature was raised to 55°C, and 0.50 g of sodium hydroxide was added every half an hour for a total of ten ...

Embodiment 2

[0032] Dissolve 4.32g of 3-methoxyphenyl 1,4-hydroquinone and 6.68g of decafluorobiphenyl in 50ml of N,N-dimethylacetamide, add 4g of cesium fluoride as a catalyst, and heat the mixture to 60 ℃, react at this temperature for 18h. The reactant was precipitated in a large amount of methanol, washed with water several times, and dried to obtain a white solid. The upper product was dissolved in 30 mL of dichloromethane, and the reaction temperature was kept at about 0°C during the ice bath reaction. Then slowly drip in containing BBr 3 CH 2 Cl 2 Solution 10mL, of which BBr 3 The content of 12.0mmol. After the addition is complete, react at room temperature for 24 hours. The reactant was precipitated in methanol, washed with water several times, and dried to obtain a white solid product. The upper reaction product was dissolved in 20 mL of epichlorohydrin, the temperature was raised to 55°C, and 0.50 g of sodium hydroxide was added every half an hour for a total of ten times. Th...

Embodiment 3

[0036] 2.16g 3-methoxyphenyl 1,4-hydroquinone, 2.42g 2,2,3,3,4,4,5,5,6,6,7,7-dodecafluoro-1,8 -Octanediol and 6.68g decafluorobiphenyl are dissolved in 50ml N,N-dimethylacetamide, 4g cesium fluoride is added as a catalyst, the mixture is heated to 60°C, and reacted at this temperature for 18h. The reactant was precipitated in a large amount of methanol, washed with water several times, and dried to obtain a white solid. The upper product was dissolved in 30 mL of dichloromethane, and the reaction temperature was kept at about 0°C during the ice bath reaction. Then slowly drip in containing BBr 3 CH 2 Cl 2 的 solution 5mL, of which BBr 3 The content is 6.06mmol. After the addition is complete, react at room temperature for 24 hours. The reactant was precipitated in methanol, washed with water several times, and dried to obtain a white solid product. The upper reaction product was dissolved in 20 mL of epichlorohydrin, the temperature was raised to 55°C, and 0.50 g of sodium hy...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Dispersion | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com