Automatic rotating mechanical worktable

A technology of rotating machinery and worktable, applied in the field of foundry, can solve the problems of high labor intensity of workers, affecting the combination of sand cores, damage of sand cores, etc., and achieve the effects of improving combination efficiency, improving yield and convenient use.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

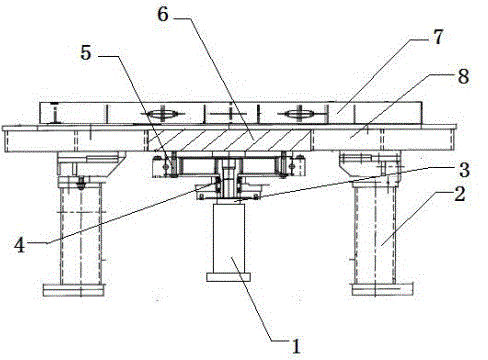

[0013] This embodiment provides an automated rotating machinery workbench, characterized in that: the automated rotating machinery workbench includes a hydraulic cylinder (1), a support column (2), a hydraulic piston (3), and a coupling (4) , fixed tooling (5), turntable (6), workbench (7), fixed chuck (8);

[0014] Wherein: a fixed chuck (8) is fixed on the supporting column (2), the fixed chuck (8) is a workbench (7), and the turntable (6) arranged in the workbench (7) and the fixed chuck (8) connection, the turntable (6) is connected to the driving device, the driving device includes the hydraulic cylinder (1), the hydraulic piston (3) and the coupling (4), the hydraulic piston (3) and the coupling (4) of the hydraulic cylinder (1) ) connection, the driving device is connected to the lower side of the turntable (6) through the fixed tooling (5), the fixed chuck (8) is circular, and the inner ring is provided with a slideway that matches the pulley of the turntable (6).

[...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com