Patents

Literature

35results about How to "Meet the requirements of modern production" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

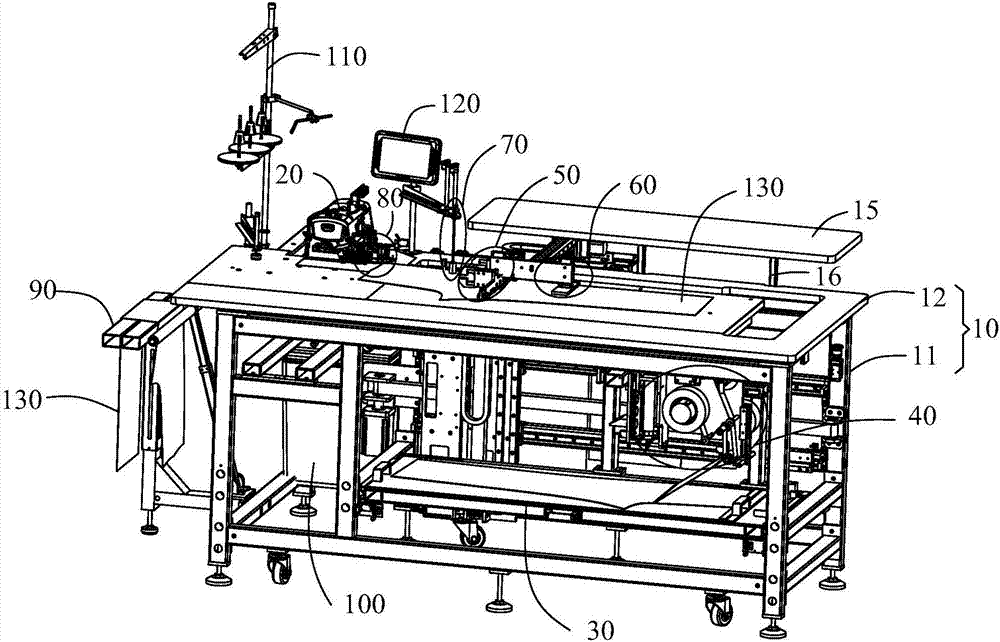

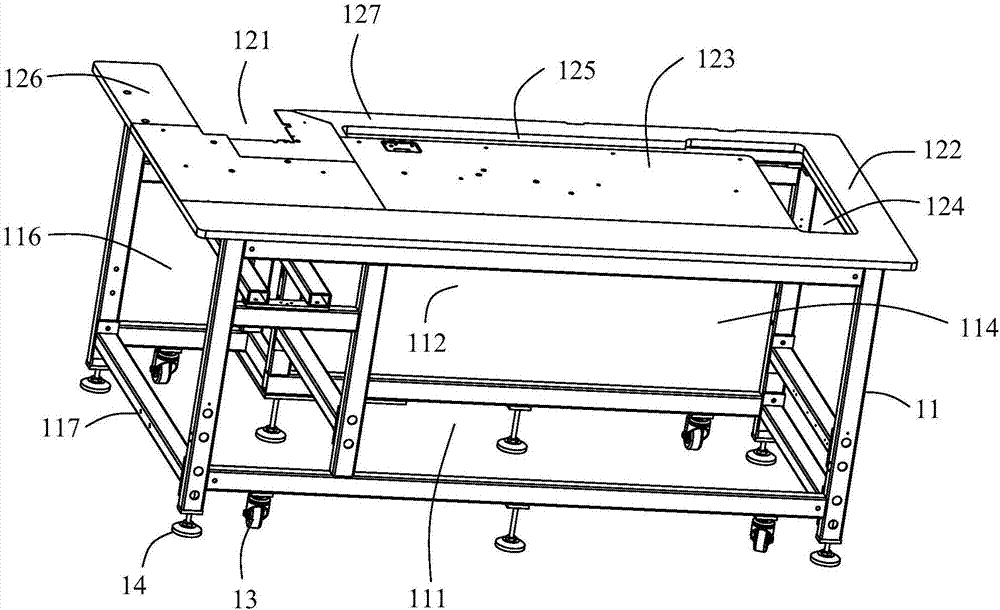

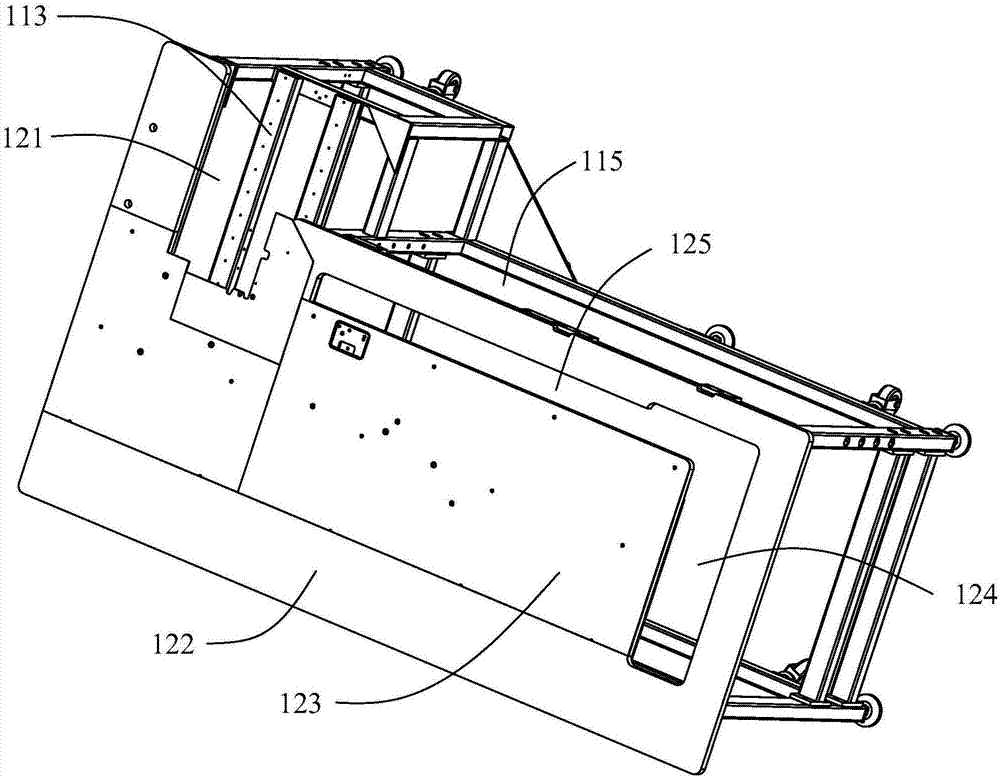

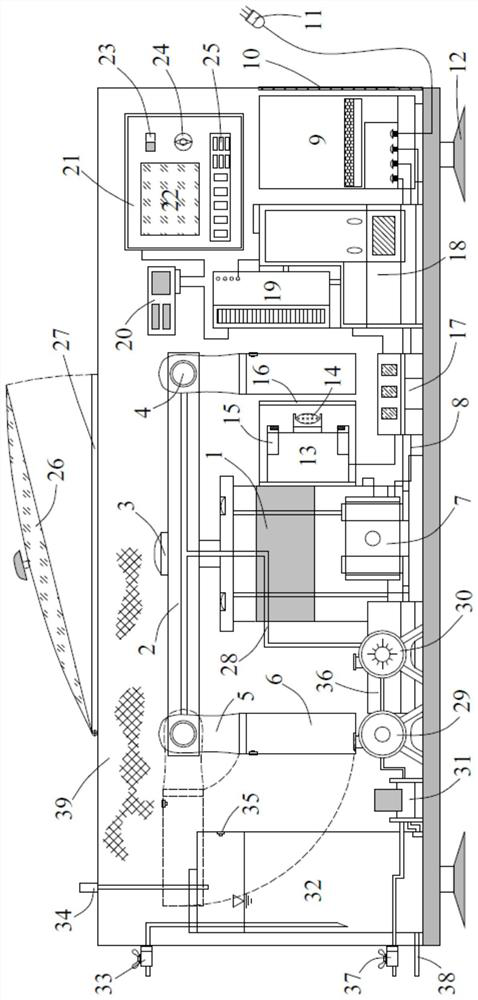

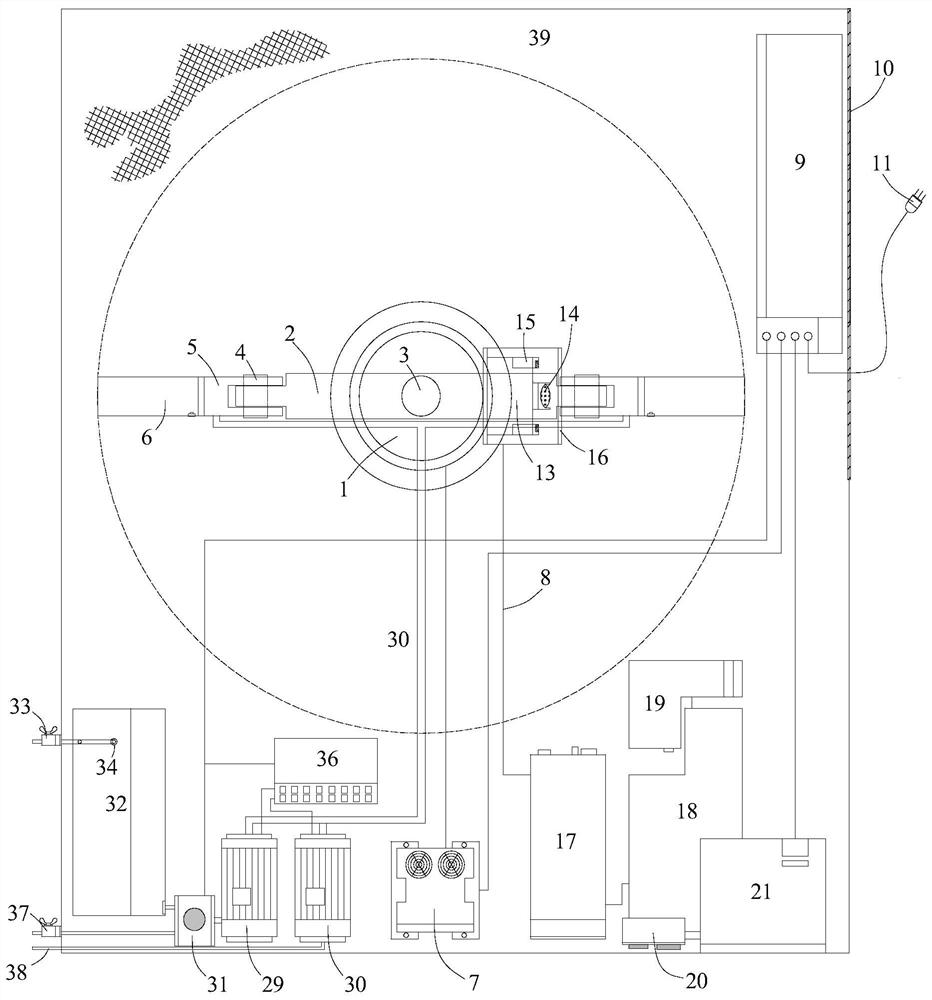

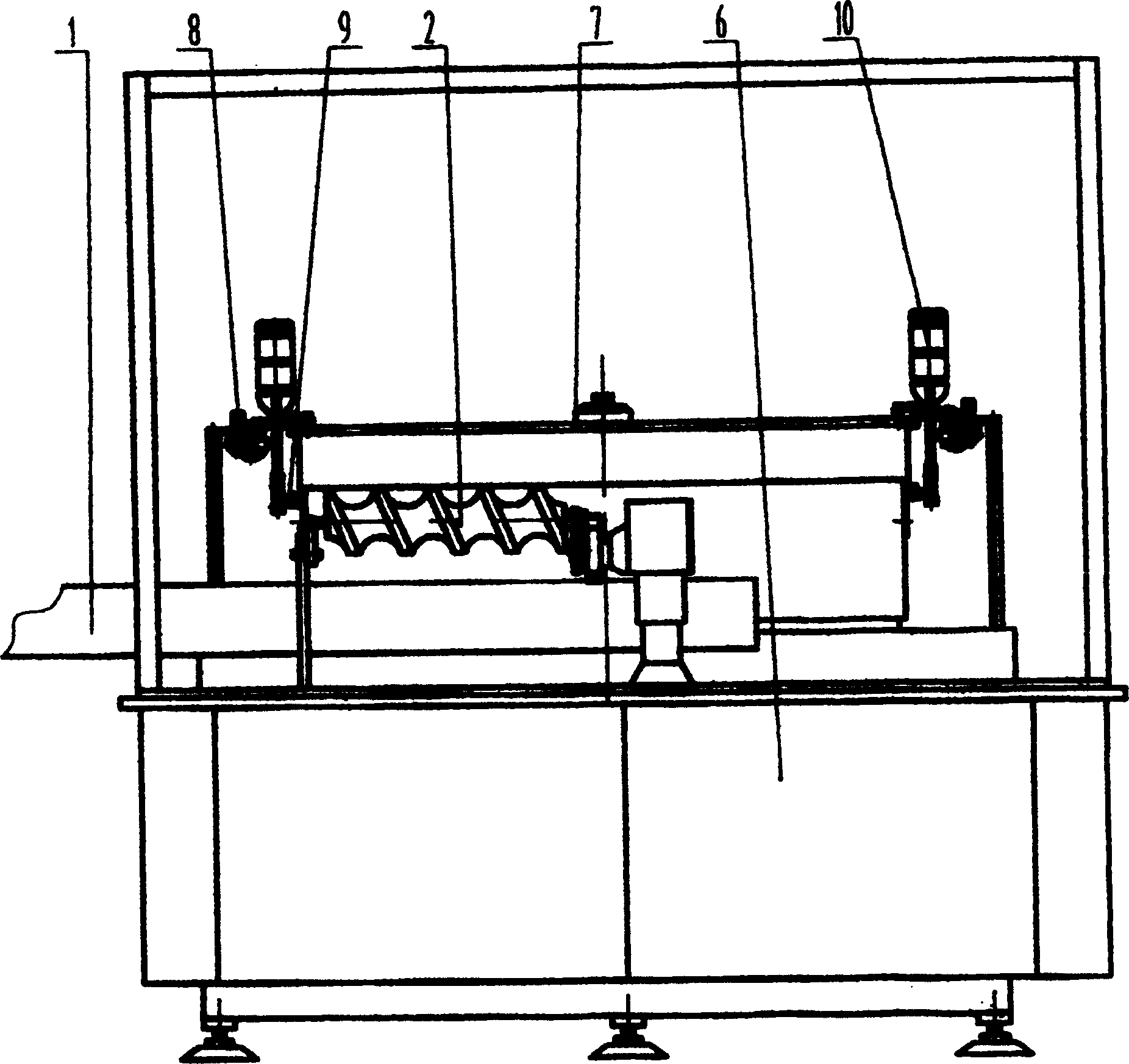

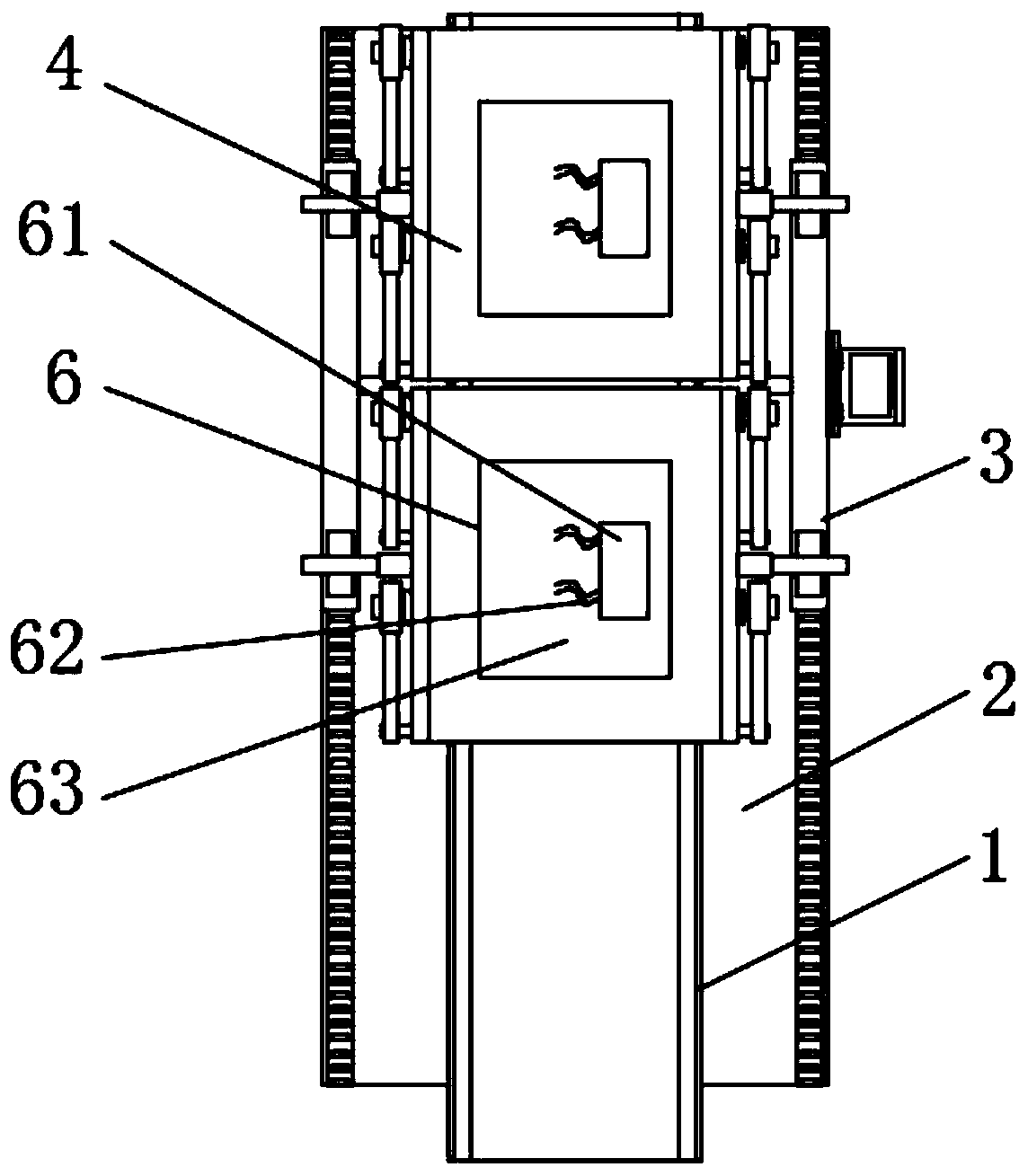

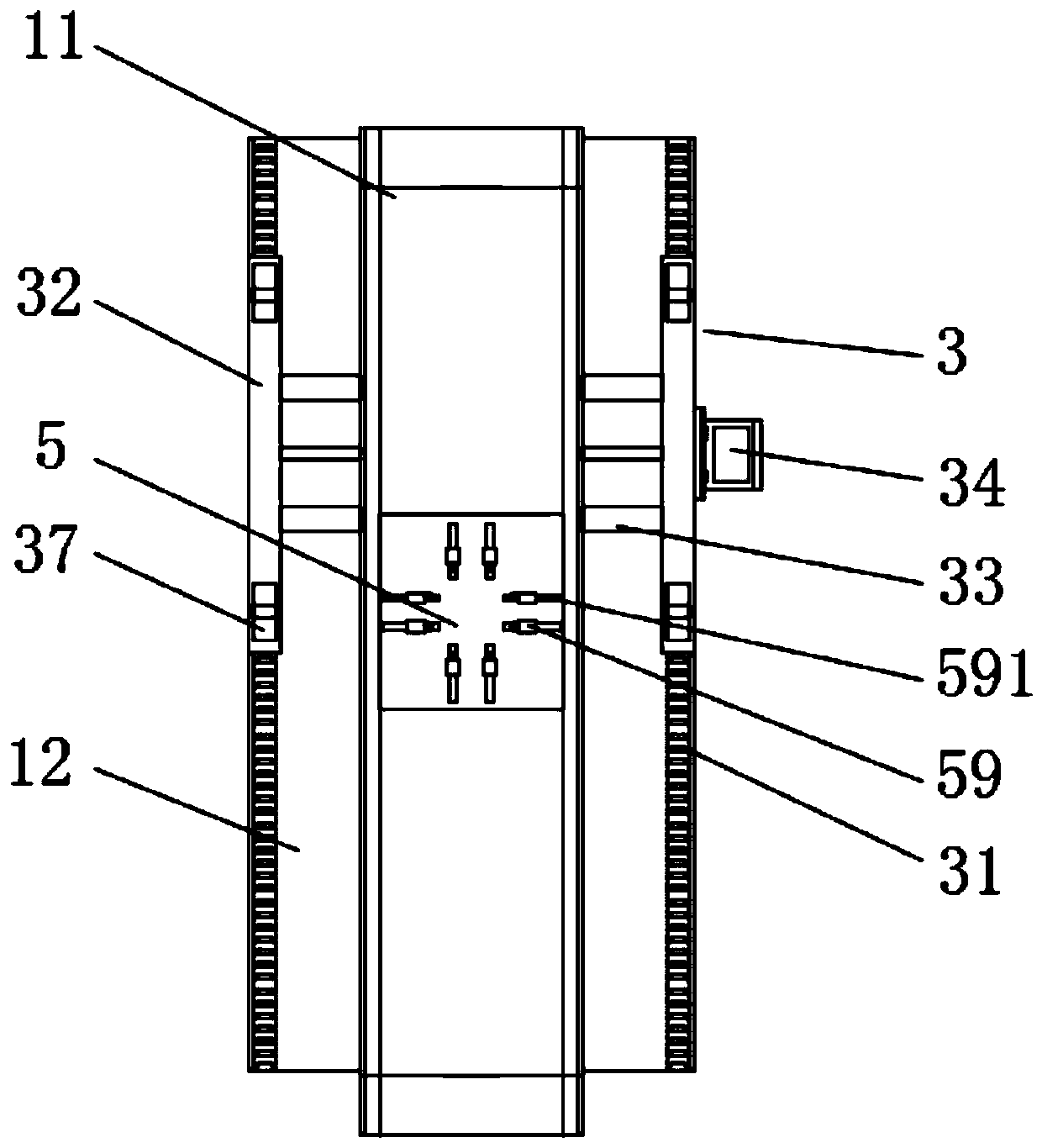

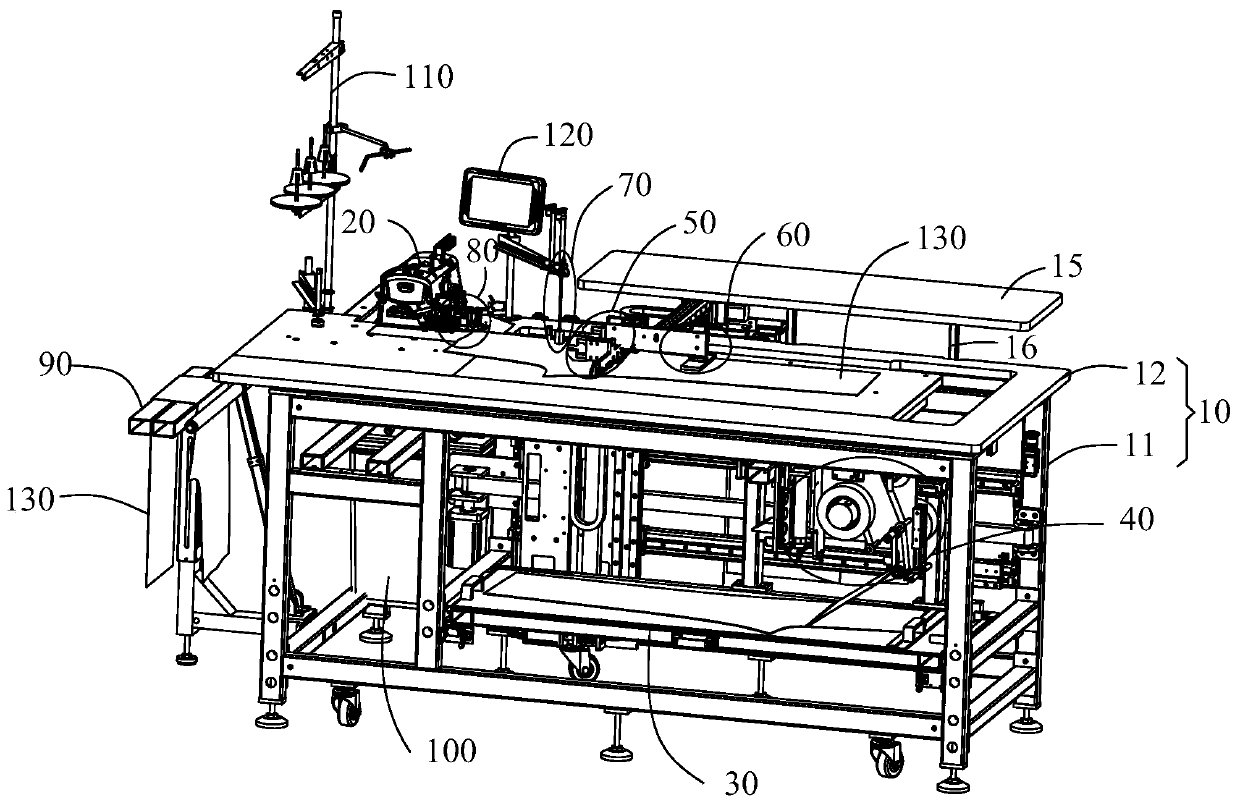

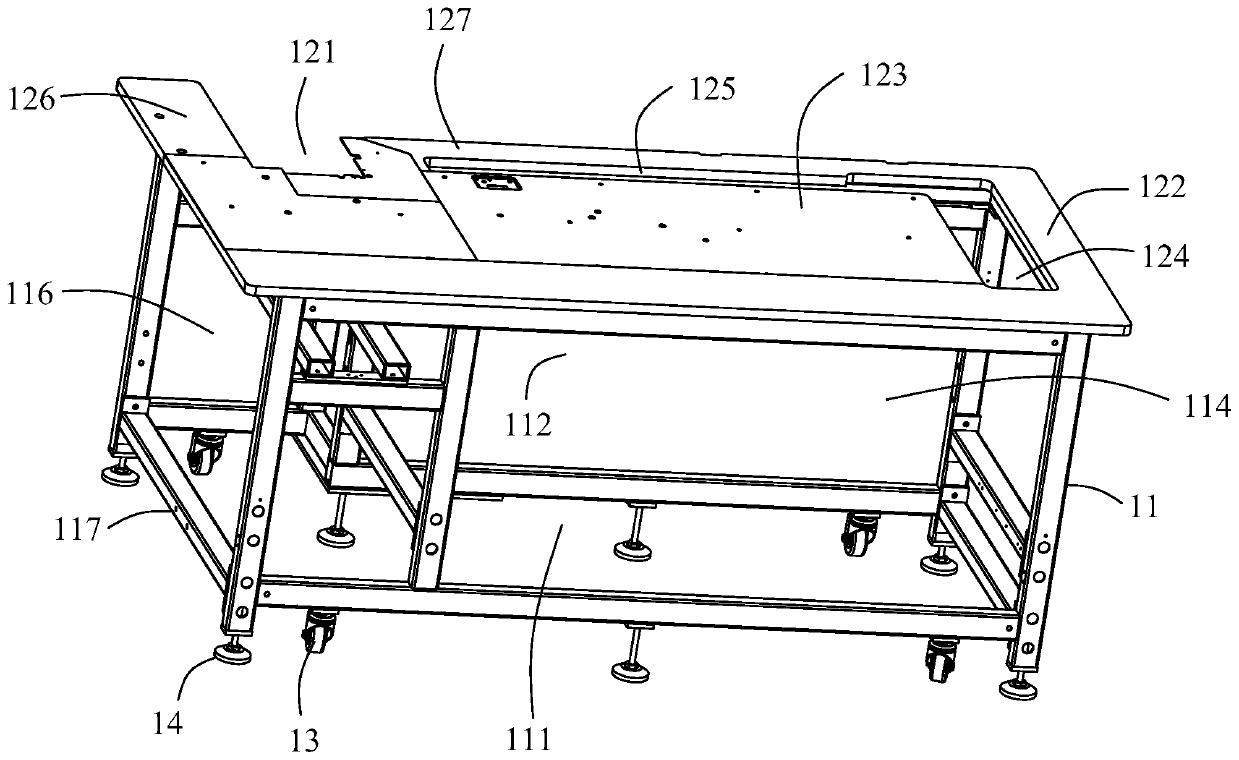

Automatic sewing equipment

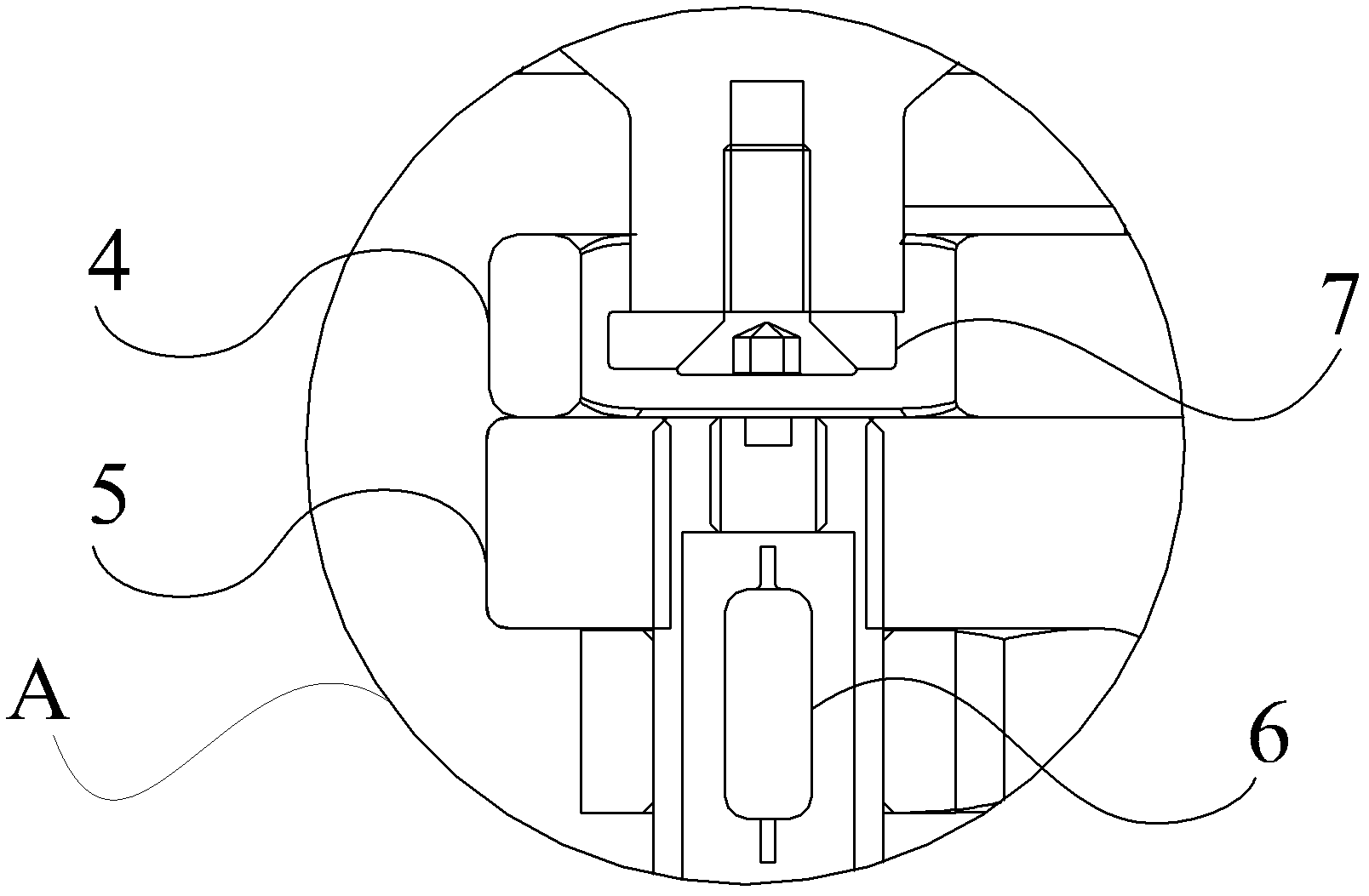

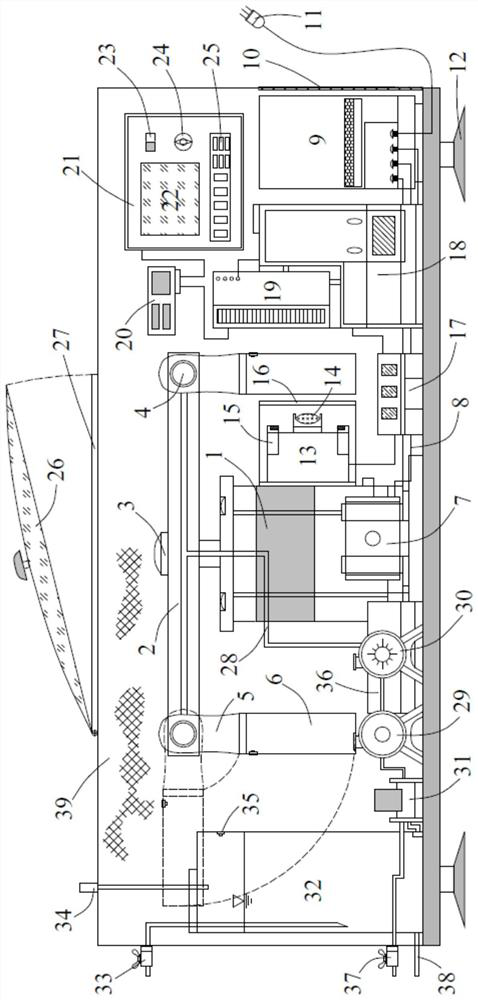

ActiveCN107475909AKeep tidy and organizedRealize fully automatic sewingProgramme-controlled sewing machinesWork-feeding meansEngineeringAutomatic testing

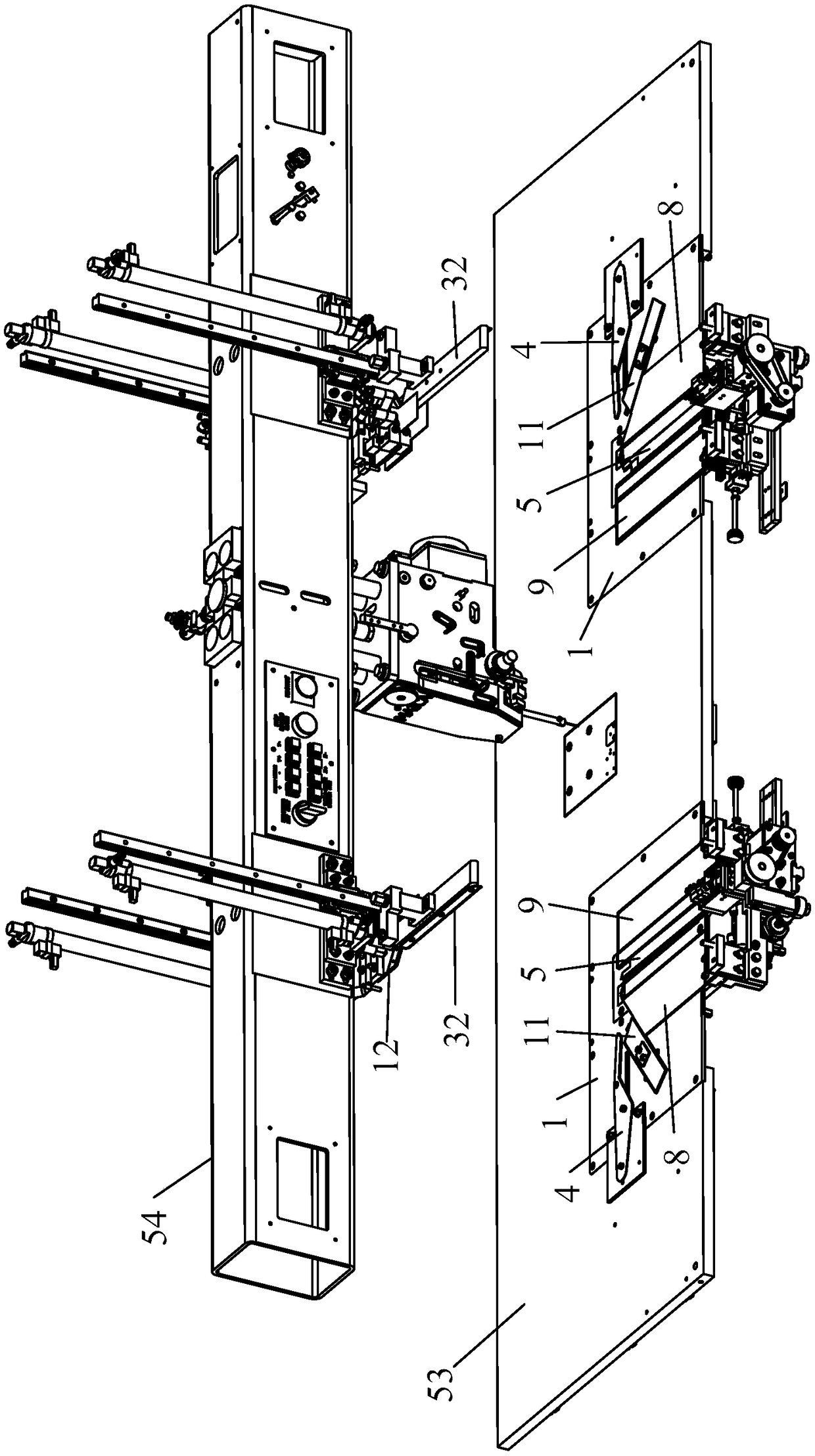

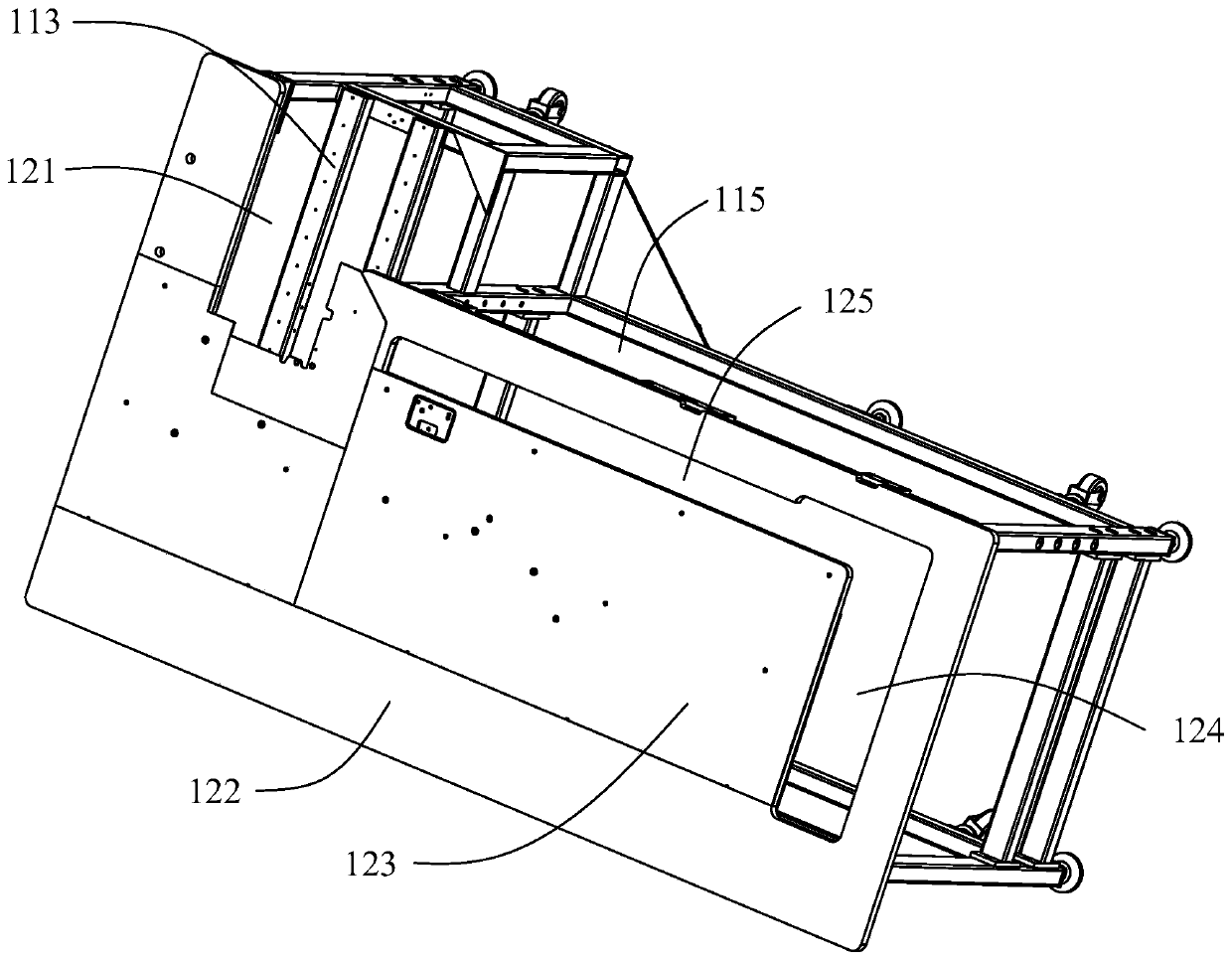

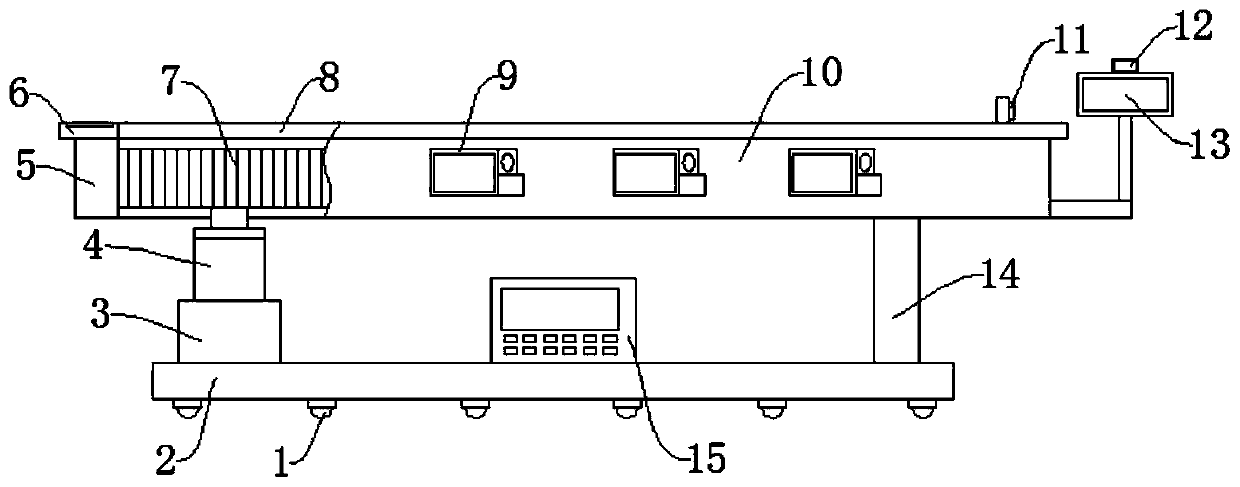

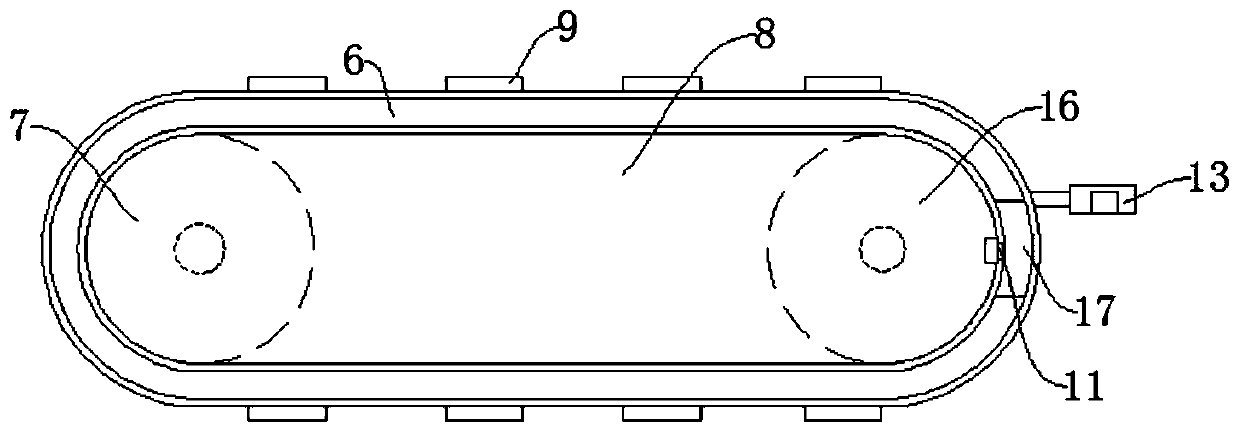

The invention provides automatic sewing equipment. The automatic sewing equipment is provided with a rack, a sewing unit, a discharging unit, a sewing material separating unit, a sewing material clamping unit, a sewing material moving unit and a collecting unit. After an operating worker places a pile of cutting pieces (multiple pieces of sewing material vertically stacked) to be sewed on a cloth placing platform, subsequently a piece of sewing material on the top layer on the cloth placing platform is separated out by the sewing material separating unit, the separated sewing material is clamped by the sewing material clamping unit and transferred to a platform plate, the sewing material on the platform plate is transferred to a sewing machine by the sewing material moving unit, the sewing material is sewed by the sewing machine, and the sewed sewing material is supported by the collecting unit, so that full automatic sewing is achieved, it is only necessary for the operating worker to place a pile of cutting pieces on the cloth placing platform, the labor cost and the manpower cost are greatly reduced, it is effectively ensured that a sewing workshop of a clothing factory is clean and orderly, and the requirements of modern production are met.

Owner:JACK SEWING MASCH CO LTD

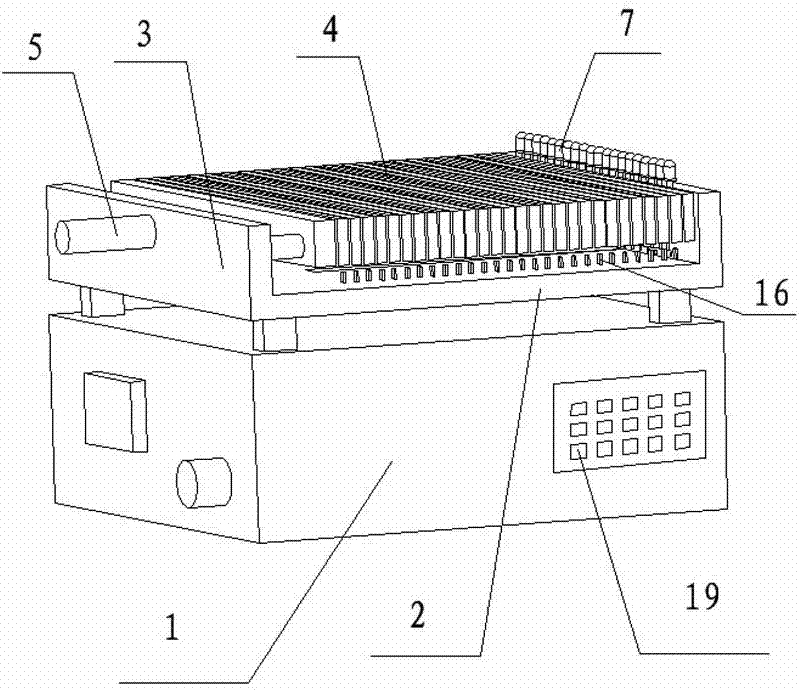

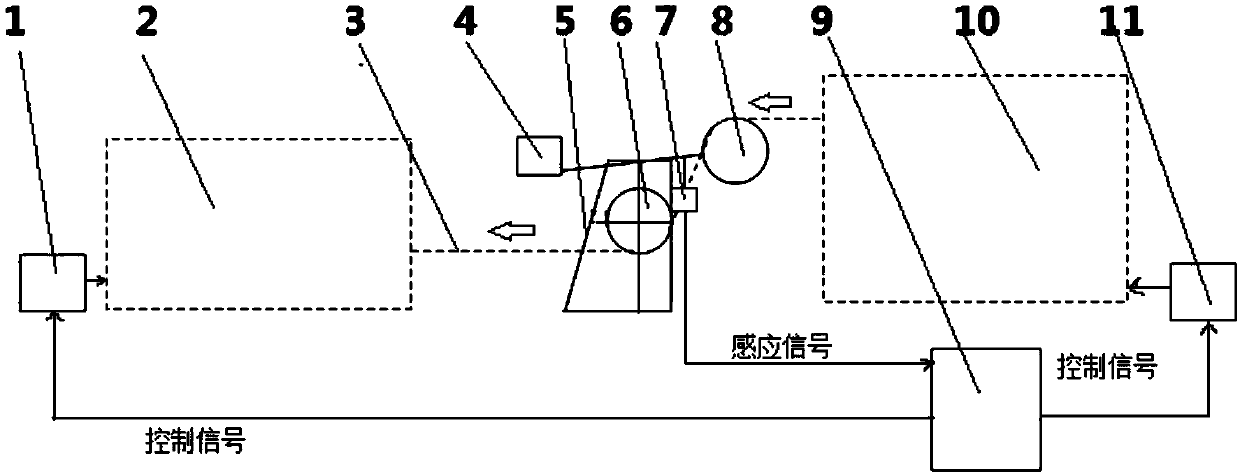

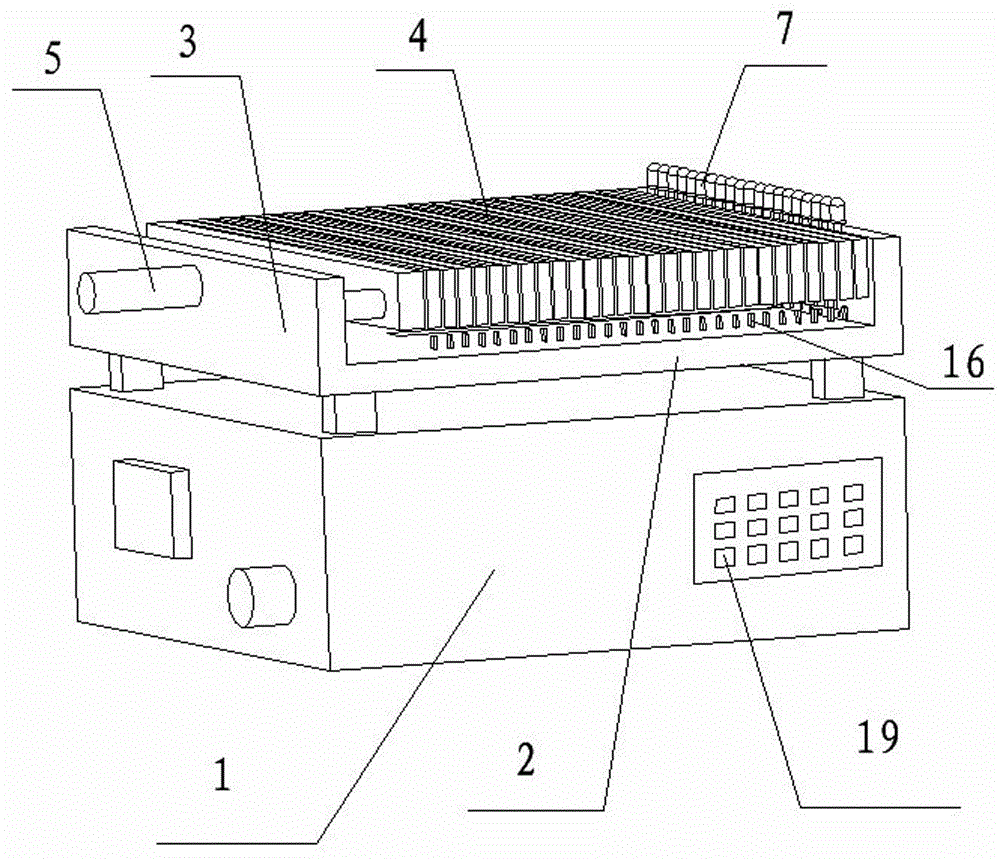

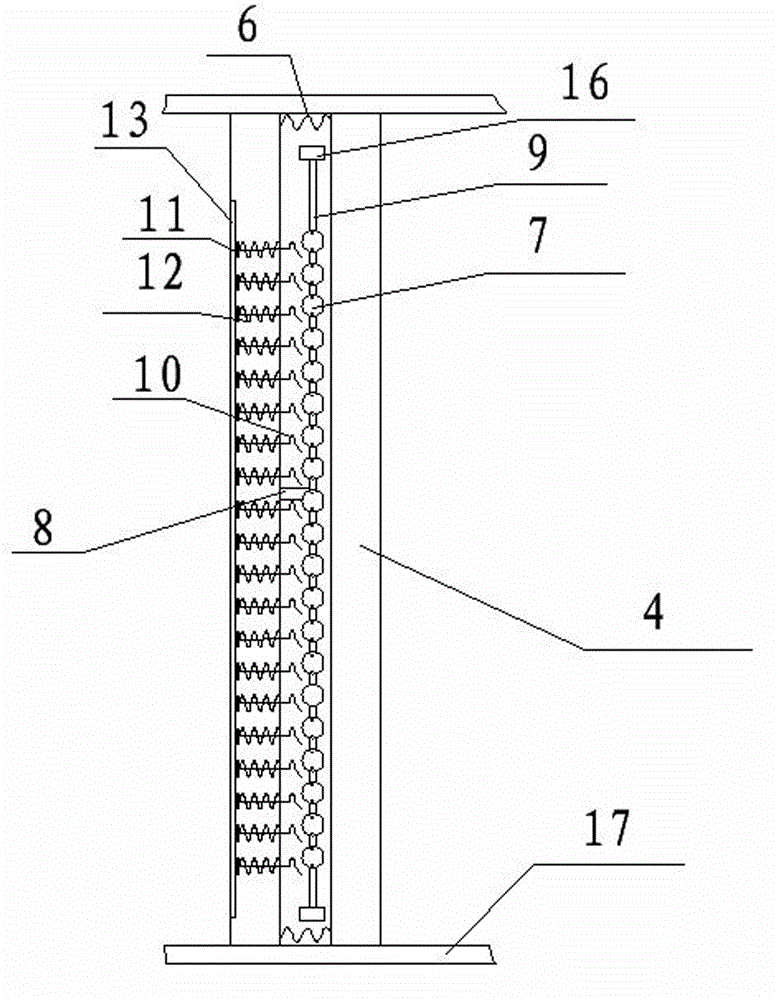

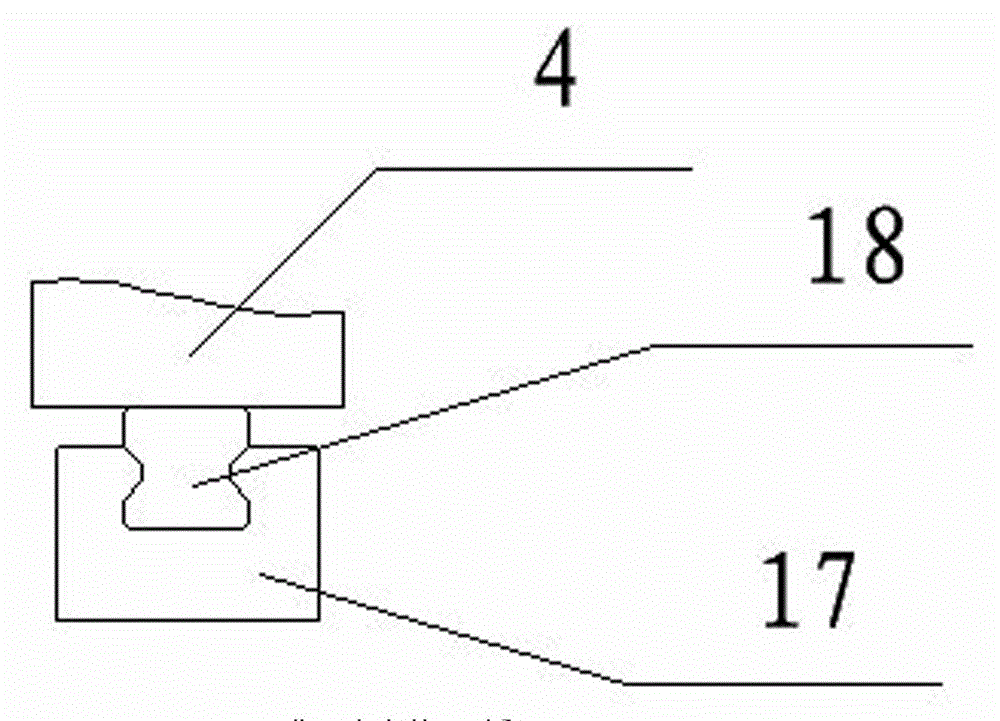

LED (Light Emitting Diode) ageing detection screening equipment and method

ActiveCN102172580AExtend detection timeImprove detection efficiencySortingIndividual semiconductor device testingPower flowControl system

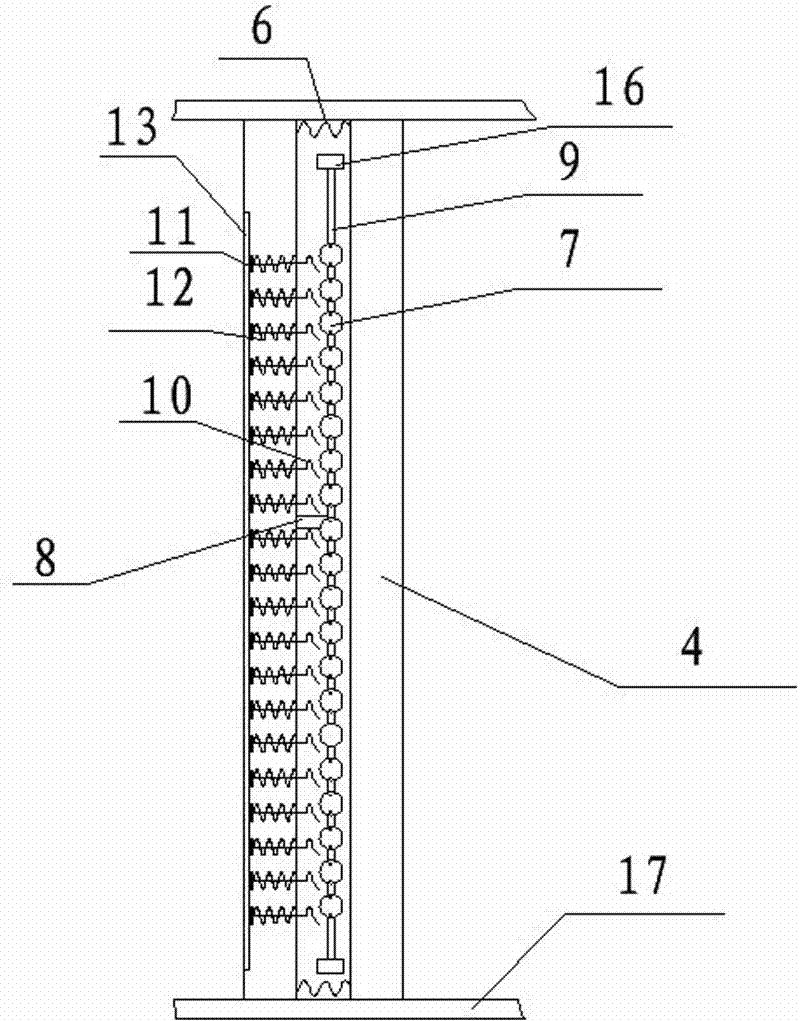

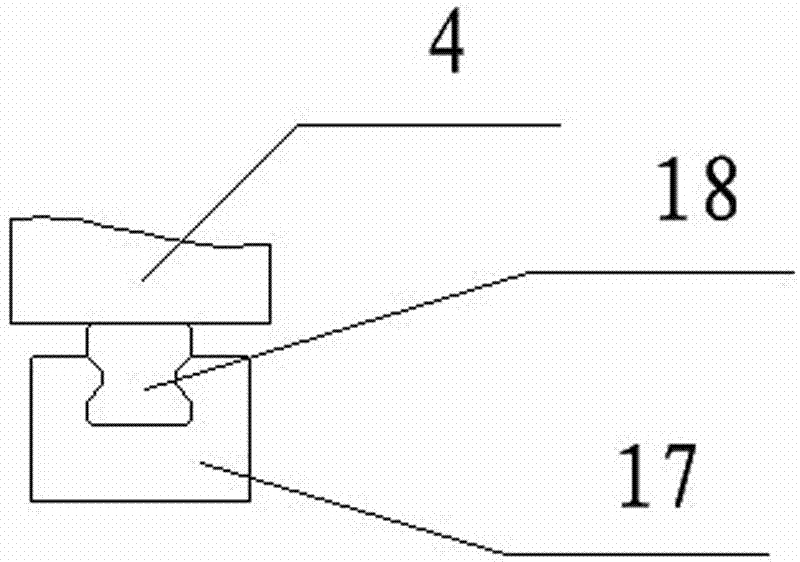

The invention discloses LED (Light Emitting Diode) ageing detection screening equipment and method. In the equipment, a push rod is driven by a power device to make each splint press towards a corresponding LED row and a corresponding LED cathode pin is in contact with a corresponding cathode contact, so that electrification of LEDs is realized; meanwhile, detection screening of the LEDs is realized by using a PC (Personal Computer) machine. In the entire ageing process, rated voltage output by a circuit control system is kept at 24V, the rated current output is 50mA, current and voltage input to the LEDs are adjustable, and the rated current and rated voltage are supplied to the ageing of the LEDs for 20-60 minutes; through ageing, LEDs with electrical and process hidden troubles can be eliminated; and after ageing, the power device stops acting on the push rod and each splint returns to an initial position under the action of the acting force of a return spring, so that detection ofLEDs is realized and defective LEDs are eliminated.

Owner:JIANGMEN JIANGHAI DISTRICT KAIHUI PHOTOELECTRIC EQUIP CO LTD

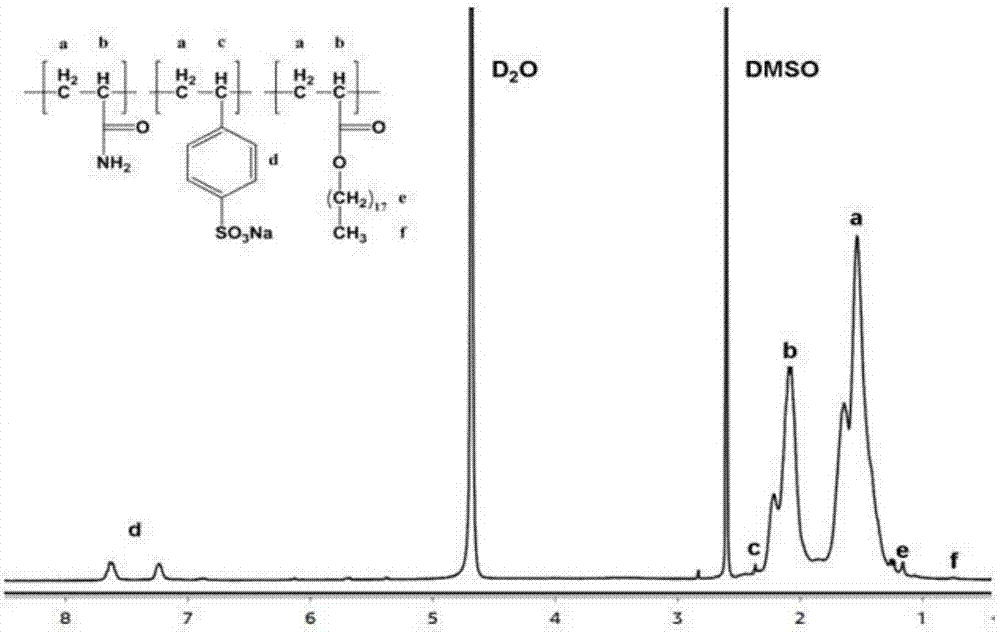

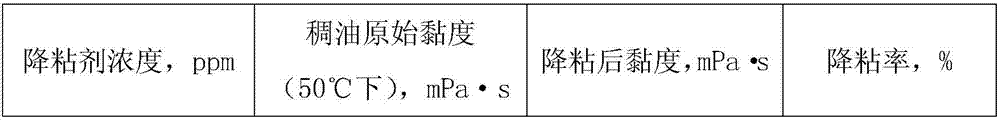

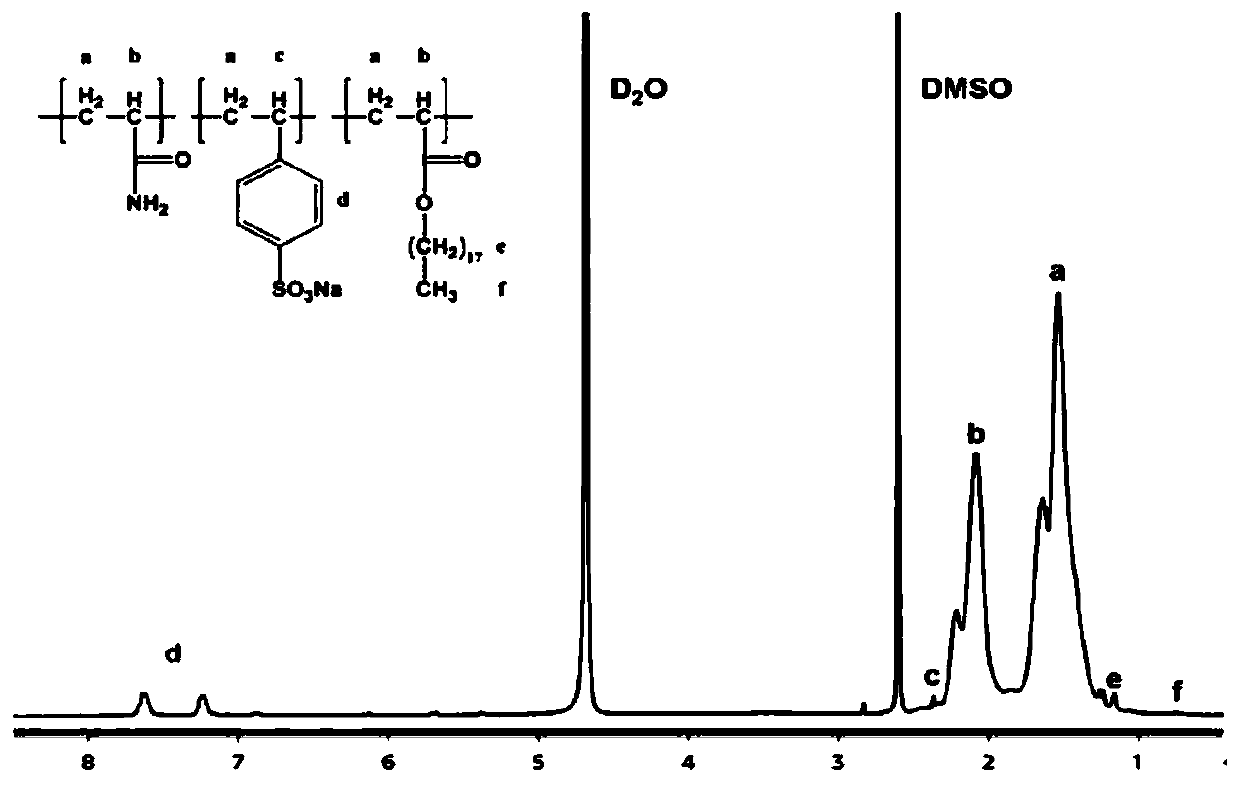

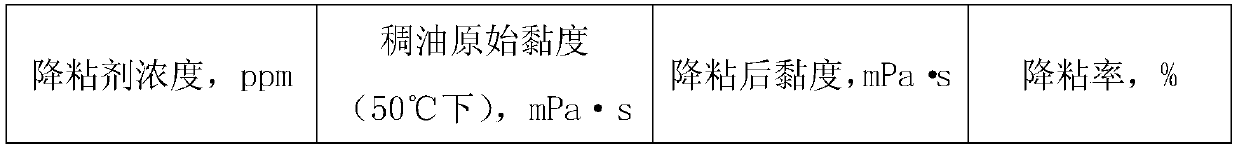

Self-demulsification heavy oil viscosity reducer as well as preparation method and application thereof

ActiveCN107955592AImprove surface activityHigh molecular weightFluid removalDrilling compositionOil viscosityRaw material

The invention relates to a self-demulsification heavy oil viscosity reducer as well as a preparation method and application thereof. The preparation method is characterized in that the self-demulsification heavy oil viscosity reducer is prepared by taking acrylamide, sodium p-styrenesulfonate and octadecyl acrylate as main raw materials; the selected raw materials have low cost and can be preparedinto the self-demulsification heavy oil viscosity reducer by adopting a simple traditional preparation process; meanwhile, an obtained product has high yield and has great advantages in a productionlink of a product; besides, the self-demulsification heavy oil viscosity reducer disclosed by the invention has the advantages of excellent viscosity reduction capability, good temperature and salt resisting effects, more outstanding viscosity reduction effect of extra-heavy oil and self-demulsification performance; integration of viscosity reduction and demulsification can be realized, and efficient oil extraction is realized.

Owner:SHANDONG UNIV

Sand shooting device

The invention discloses a sand shooting device. The device comprises a cylinder body, wherein a sand feeding port is formed at the upper end of the cylinder body, and a shooter is arranged at the lower end of the cylinder body; an air blowing cavity is formed at the upper part of the cylinder body and is communicated with the sand feeding port; high-pressure air is introduced in the air blowing cavity; and a lower shooting cavity is formed at the lower part of the cylinder body, and is communicated with the air blowing cavity and the shooter respectively. When the sand shooting device is used, casting sand is added into the cylinder body through the sand feeding port; and when the casting sand passes through the air blowing cavity at the upper part of the cylinder body, the casting sand accelerates under the action of high-pressure air, and are shot out from the shooter through the lower shooting cavity so as to complete the whole sand shooting process. The sand shooting device has a simple structure, and is easy to manufacture and very convenient to use, so that the production efficiency can be effectively improved, the labor intensity of workers is reduced, and the modern production requirement is met.

Owner:SUZHOU SUZHU FOUNDRY MACHINERY MFG

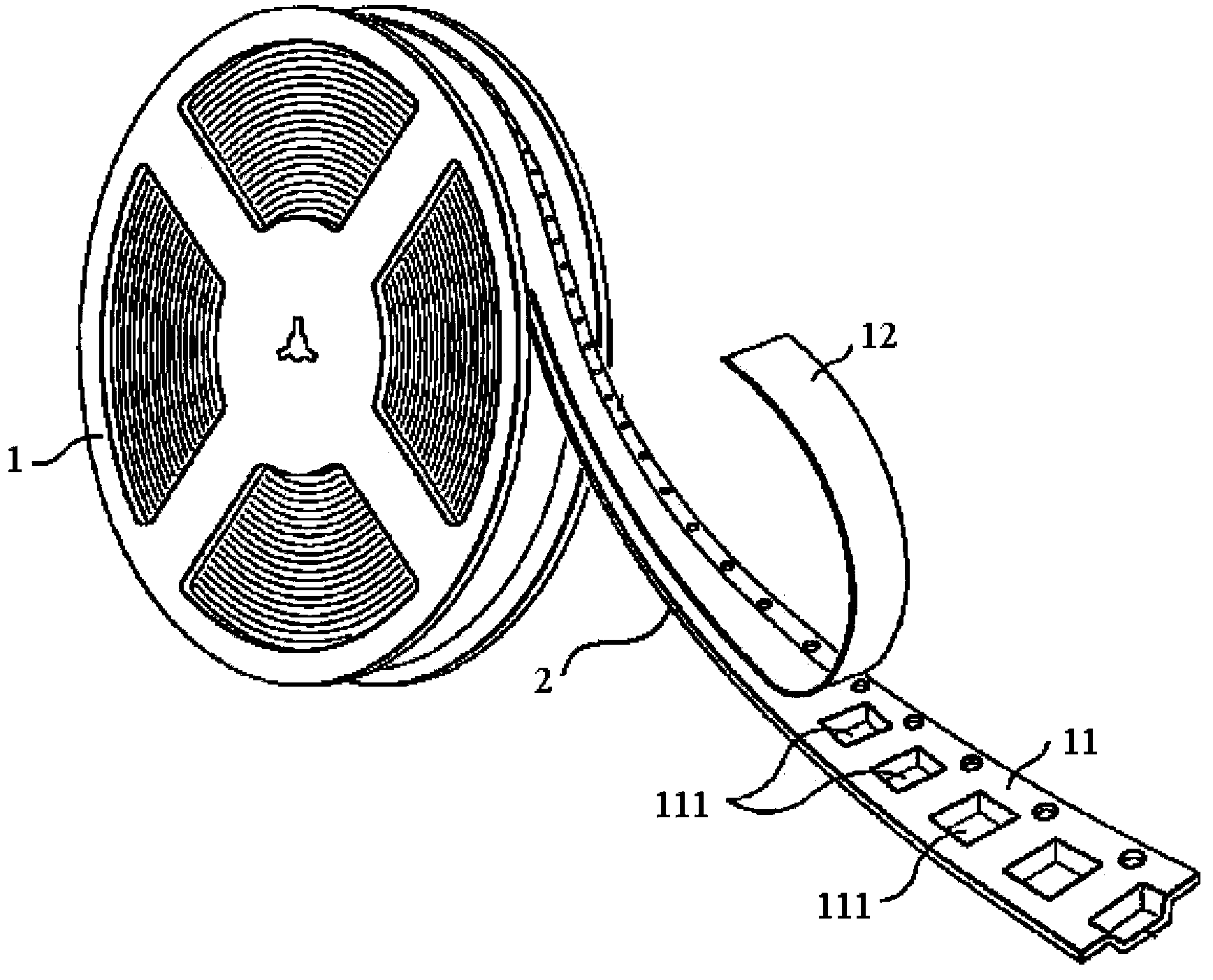

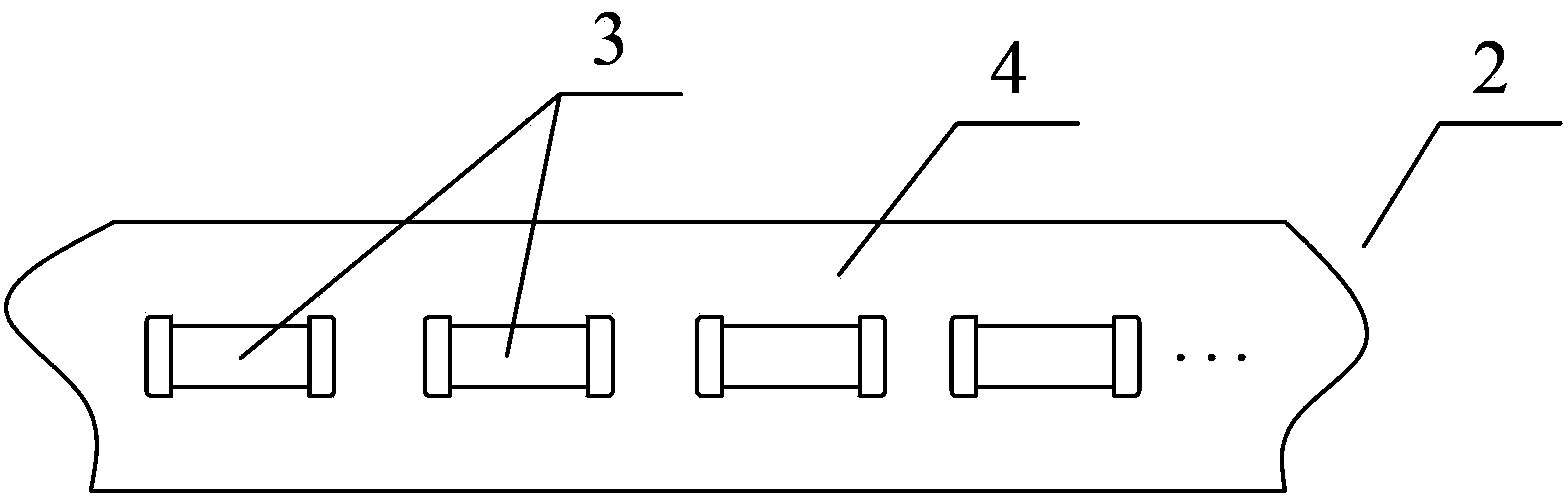

Surface-mounted electronic device package structure and manufacturing and application methods thereof

InactiveCN104340516AThe overall structure is simpleSave on packaging materialsPackagingEngineeringAdhesive

The invention provides a surface-mounted electronic device package structure comprising a plurality of surface-mounted electronic devices and a base strip; the surface-mounted electronic devices are evenly arranged side by side along the length of the base strip and are all fixed on the upper surface of the base strip through adhesive; the base strip and the surface-mounted electronic devices are made into a woven strip. The surface-mounted electronic device package structure is simple in structure and needs less packaging material; weldable portions of part of electrodes of the surface-mounted electronic devices are exposed out of the packaging material, and the packaging material need not be peeled off accordingly during mounting of the surface-mounted electronic devices; the surface-mounted electronic devices are fixed on the base strip and can be accurately conveyed to specific positions of a surface-mounter, and mounting efficiency is improved; the base strip which is split can be mounted with the surface-mounted electronic devices onto a circuit board and softens at the welding temperature to form a protective layer for the surface-mounted electronic devices, and the surface-mounted electronic devices and the circuit board are better in reliability.

Owner:弗兰克·魏

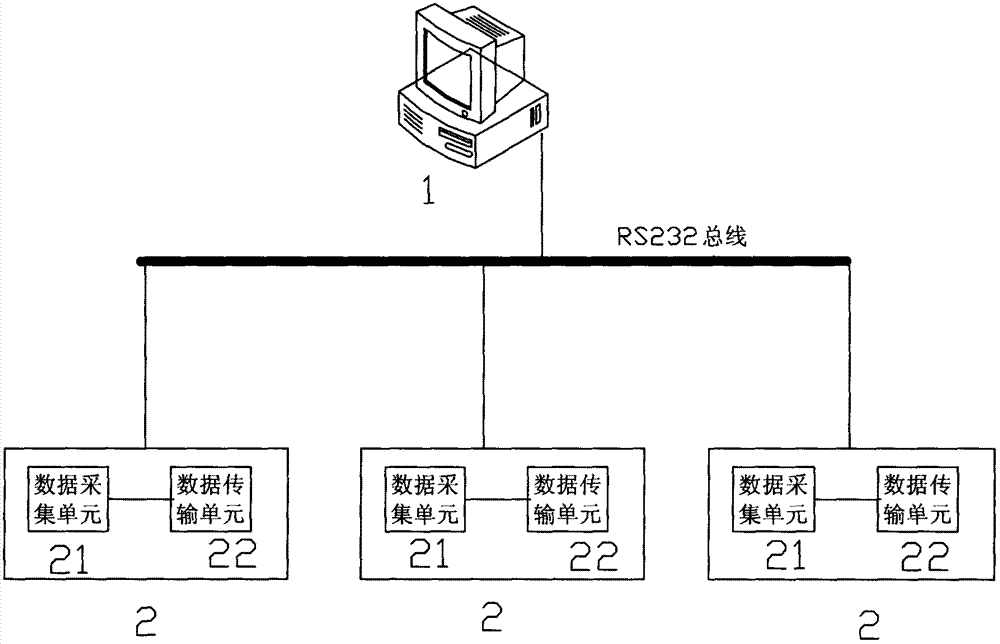

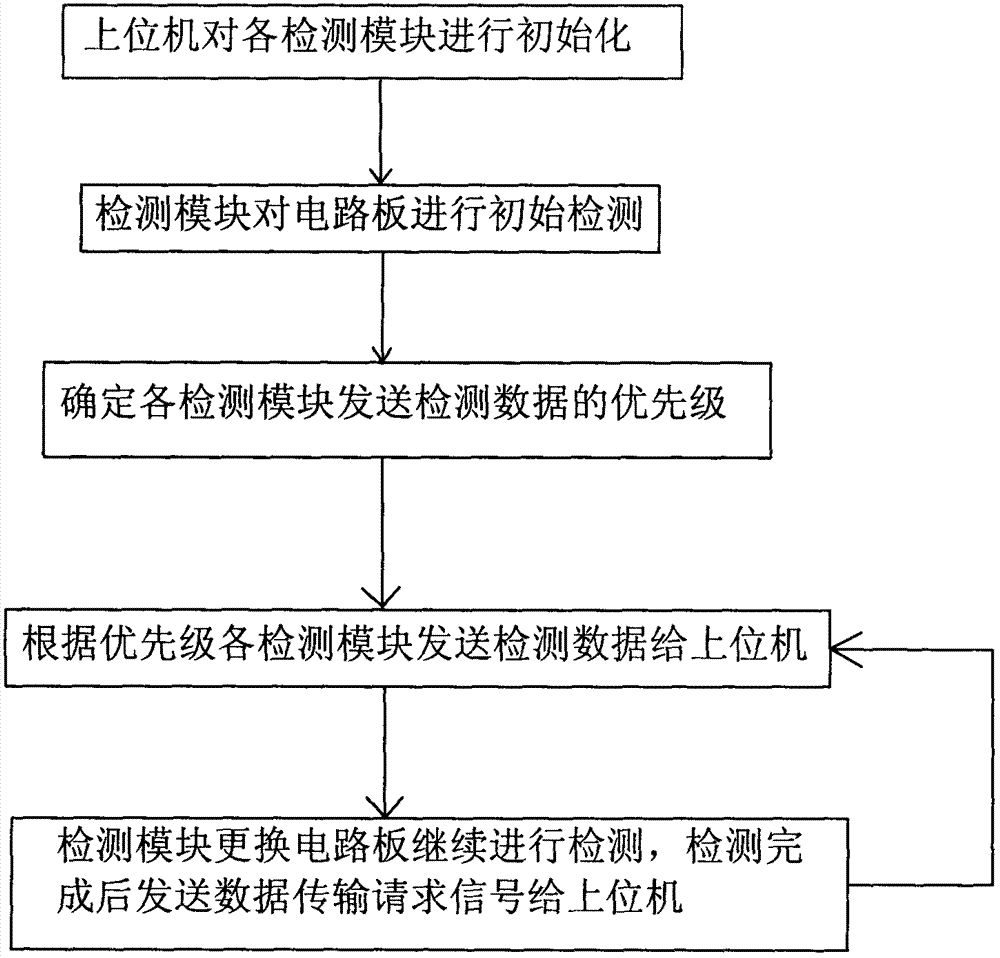

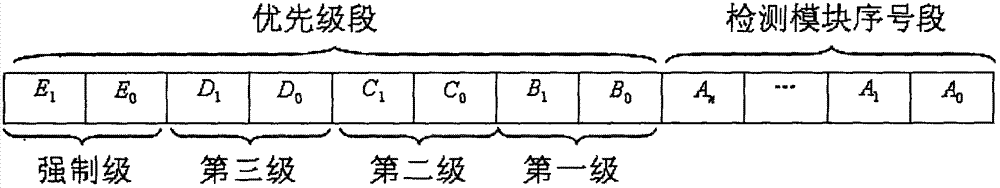

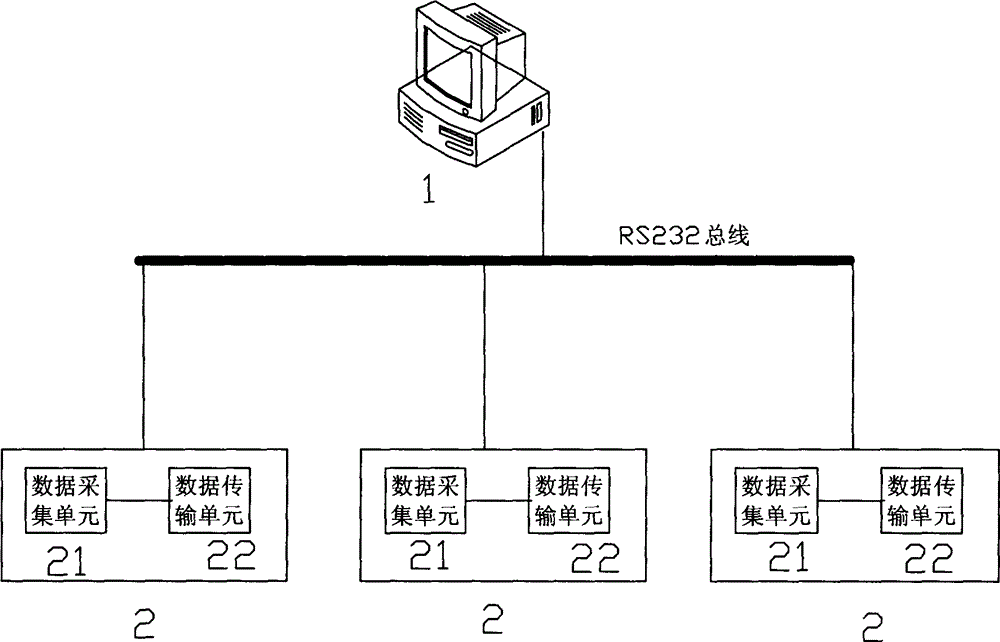

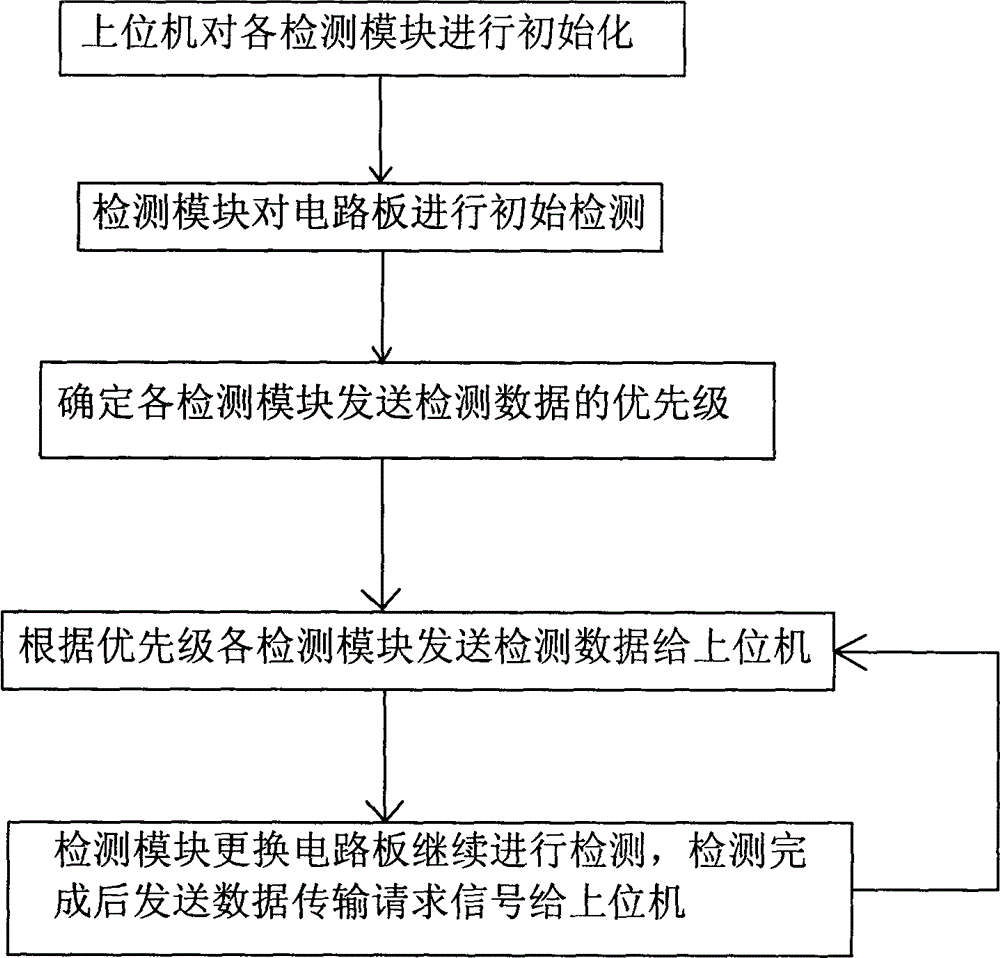

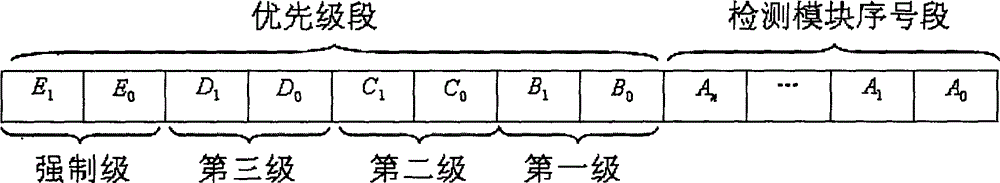

Flexibility detection system and method of circuit board

InactiveCN102736019ARealize automated detectionReduce labor intensityElectronic circuit testingSystem developmentElectrical and Electronics engineering

The invention provides a flexibility detection system of a circuit board. The flexibility detection system is connected with an upper computer and a detection module through an RS232 bus, automatically detects the circuit board through a detection module, can transmit a detection result to the upper computer to display in real time, and can simultaneously detect various circuit boards. By aiming to the difference of detection conversion time of the various circuit boards, the flexibility detection system puts forward a scheduling method of improving priority through classification inversion, automatically regulates the priority of occupied bus and reasonably allocates the time of the occupied bus. The flexibility detection system of the circuit board can realize the automatic detection on the circuit board, especially is suitable for low-cost detection of small-batch various circuit boards, can effectively improve the detection precision, reduces the labor intensity of workers, reduces the cost and the development difficulty of a system, and meets the requirements in modernization production.

Owner:NINGBO UNIVERSITY OF TECHNOLOGY

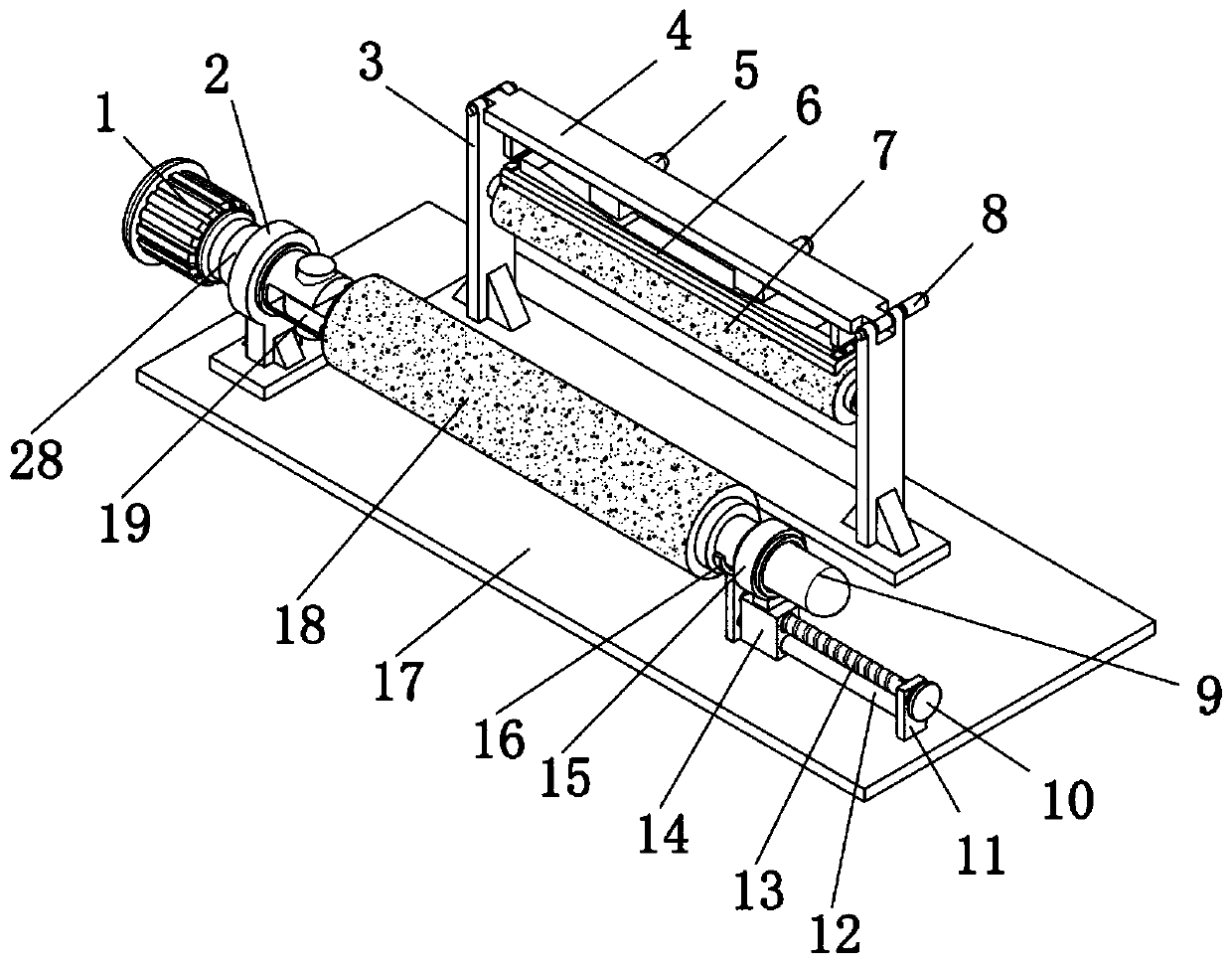

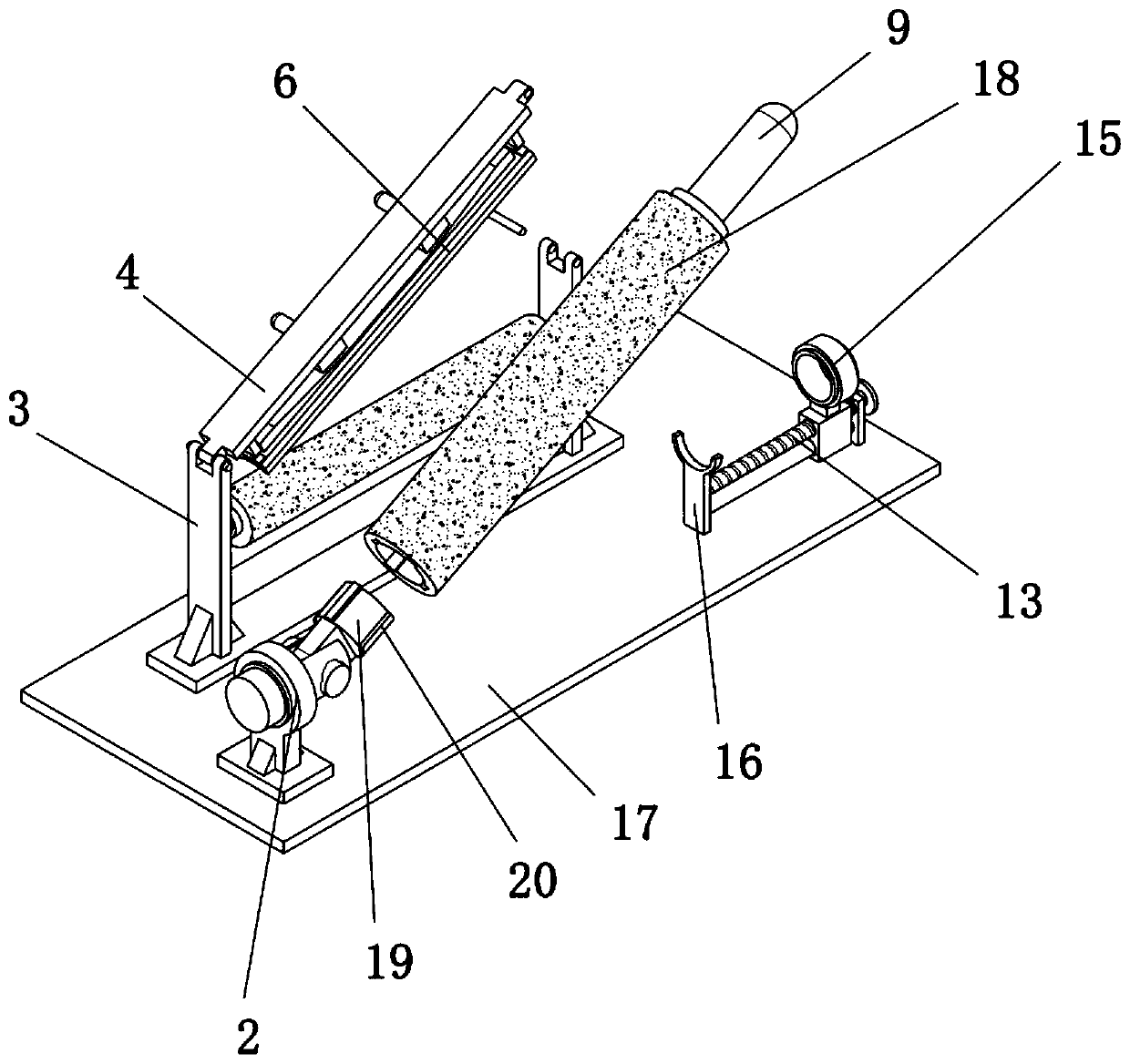

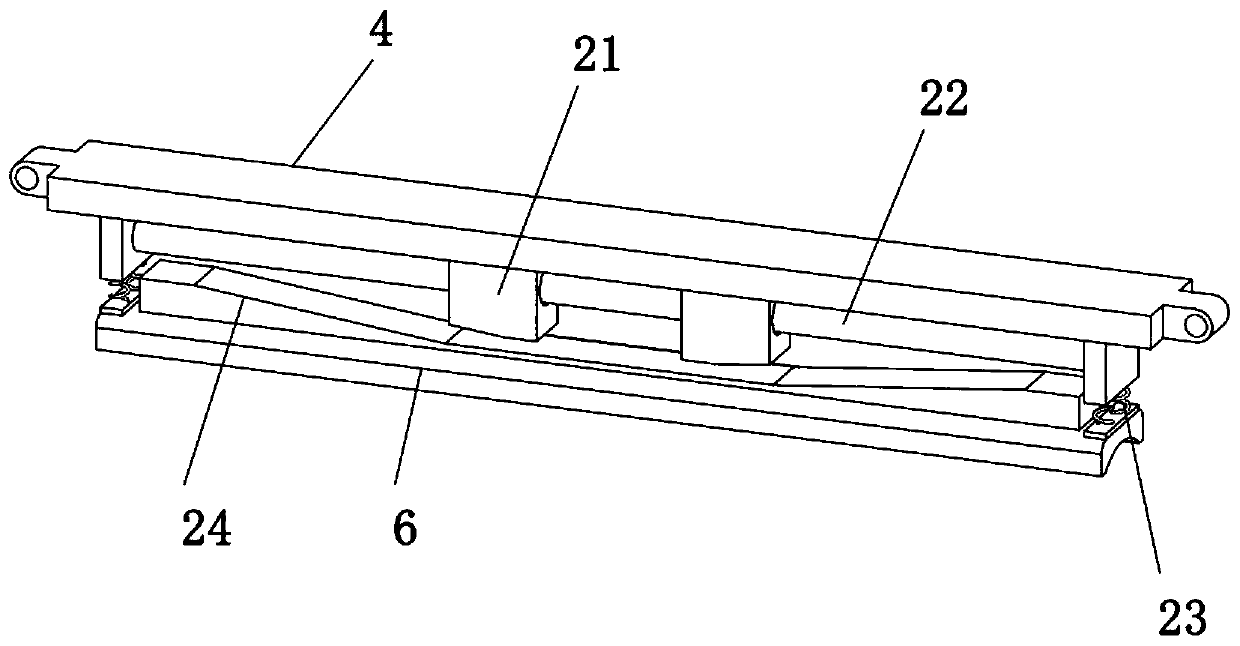

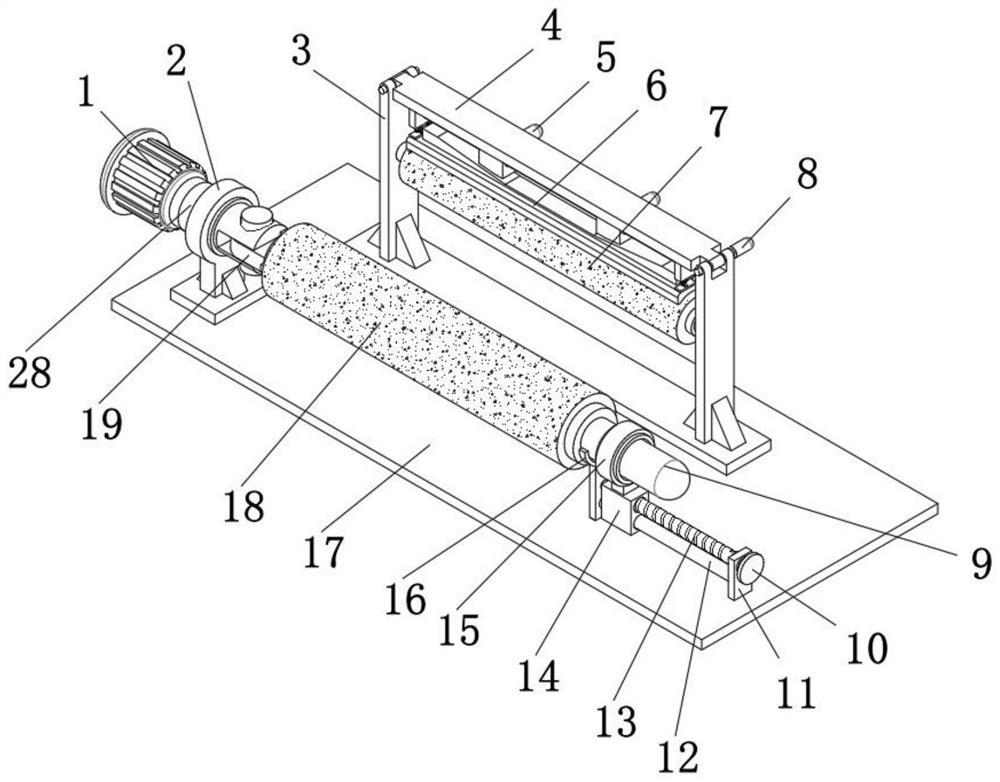

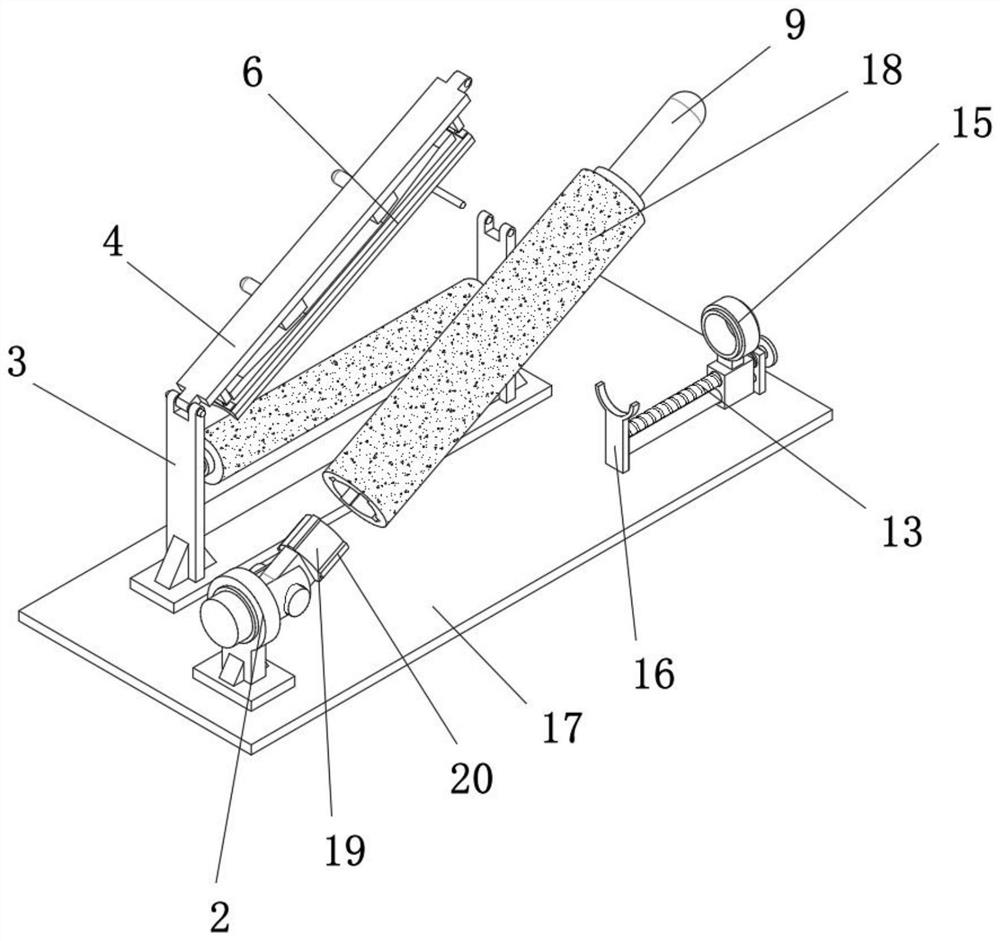

Feeding device of textile equipment

The invention discloses a feeding device of textile equipment. The feeding device comprises a bottom plate, wherein a cloth winding roller is arranged on one side of the top of the bottom plate, and one end of the cloth winding roller is provided with a connecting pin in an embedded mode; and one end of the connecting pin is rotationally connected to a supporting pin through a pin shaft, the supporting pin is rotationally connected to the bottom plate through a supporting sleeve, the other end of the connecting pin is fixedly connected to a limiting shaft, and a threaded rod is arranged at thebottom of the limiting shaft. According to the feeding device of textile equipment, when the cloth winding roller needs to be disassembled or installed, a limiting hoop is driven to move through a rotating disc and the threaded rod, so that the limiting hoop is separated from the limiting shaft, then the cloth winding roller is inclined through lifting of the limiting shaft, and the cloth windingroller is pulled out; and if the installation is needed, the steps are operated in the reverse mode so that the cloth winding roller can be disassembled and installed, in the operation process, the rotating disc is controlled to limit the cloth winding roller, and the operation is simple and convenient.

Owner:安徽职业技术学院

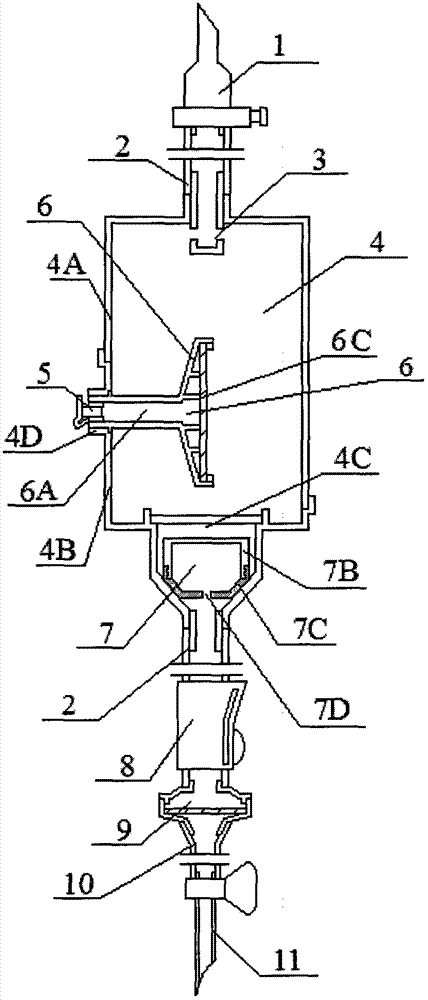

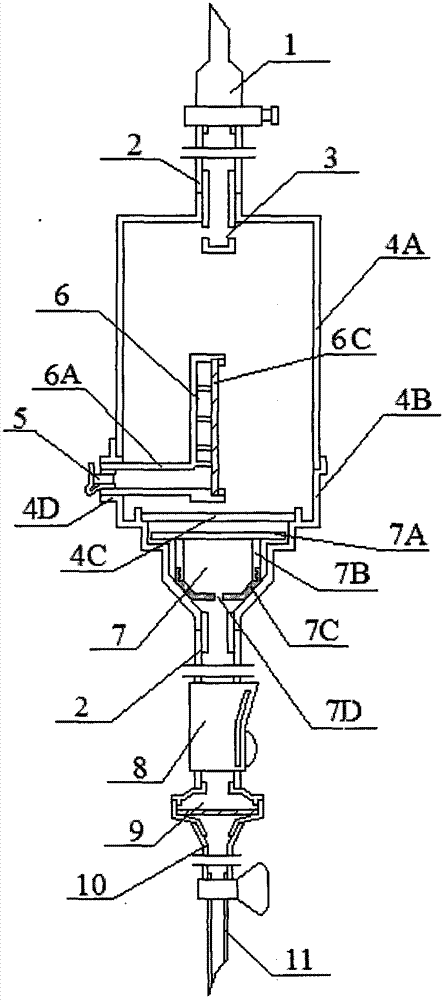

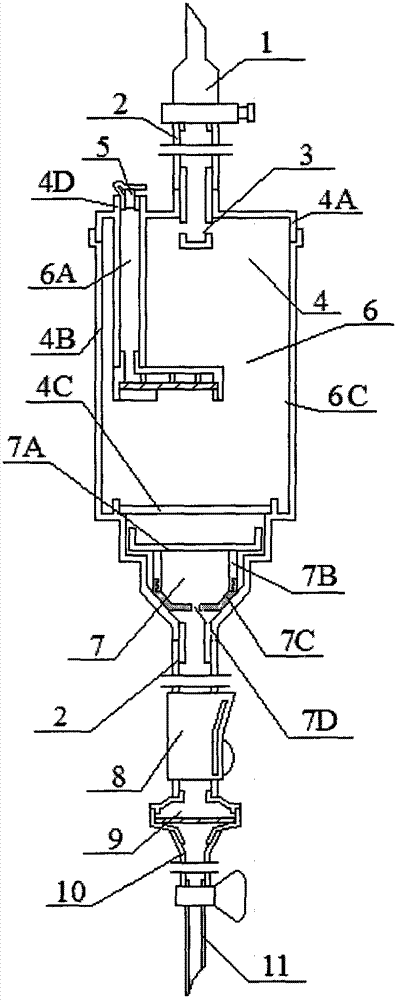

Infusion apparatus

The invention discloses an infusion apparatus which comprises a bottle stopper puncture outfit, an infusion tube, an infusion dripping tube, a dripping bucket, a lower infusion tube, an infusion stopping bucket, a flow regulator, an outer cone joint, a fine infusion tube and an intravenous injection needle and is characterized in that an infusion stopping floating plug is contained at the lower end of the dripping bucket, wherein the lower part of the infusion stopping floating plug is an inverted circular platform or an inverted circular platform ring body, the upper part of the infusion stopping floating plug is formed by adding an upper top cover on a cylinder or a circular ring cylinder, the shape and the size of the lower end of the dripping bucket are matched with those of the infusion stopping floating plug; a waterproof air filter which is connected with a dripping bucket wall through an exhaust tube is installed in the dripping bucket, and a sealing plug is also arranged at one end of the exhaust tube, which is located on the dripping bucket wall. With the adoption of the infusion apparatus, the automatic exhaust of the dripping bucket and influsion stopping after an infusion is wholly dripped can be realized, so that air can be prevented from entering into the infusion tube.

Owner:戎静华

A self-demulsifying heavy oil viscosity reducer and its preparation method and application

ActiveCN107955592BImprove surface activityHigh molecular weightFluid removalDrilling compositionOil viscosityReducing agent

The invention relates to a self-demulsification heavy oil viscosity reducer as well as a preparation method and application thereof. The preparation method is characterized in that the self-demulsification heavy oil viscosity reducer is prepared by taking acrylamide, sodium p-styrenesulfonate and octadecyl acrylate as main raw materials; the selected raw materials have low cost and can be preparedinto the self-demulsification heavy oil viscosity reducer by adopting a simple traditional preparation process; meanwhile, an obtained product has high yield and has great advantages in a productionlink of a product; besides, the self-demulsification heavy oil viscosity reducer disclosed by the invention has the advantages of excellent viscosity reduction capability, good temperature and salt resisting effects, more outstanding viscosity reduction effect of extra-heavy oil and self-demulsification performance; integration of viscosity reduction and demulsification can be realized, and efficient oil extraction is realized.

Owner:SHANDONG UNIV

Core ejecting device

The invention discloses a core ejecting device which comprises a frame. A core ejecting oil cylinder is arranged at the bottom part of the frame; a workbench is arranged above the core ejecting oil cylinder; and the workbench is connected with a piston rod of the core ejecting oil cylinder. When the core ejecting device is in use, the workbench is driven by the core ejecting oil cylinder to move upwards, so that the workbench is propped against a sand core of a sand box to eject out the sand core, and the core ejecting device is very convenient to use; a lifting oil cylinder is also arranged above the workbench; and the core ejecting capacity of the workbench can be increased through the lifting oil cylinder so as to be convenient for pushing out the sand core with larger volume. The core ejecting device has a simple structure, is convenient to use and can accelerate the ejecting-out speed of the sand core and improve the production efficiency; and moreover, with the adoption of the core ejecting device, the ejecting-out automation of the sand core from the core box can be realized, no manual operation is required, the labor is saved, and the core, in particular to the sand core with larger volume is more conveniently to eject out, therefore, the demands of modern production can be effectively met.

Owner:SUZHOU SUZHU FOUNDRY MACHINERY MFG

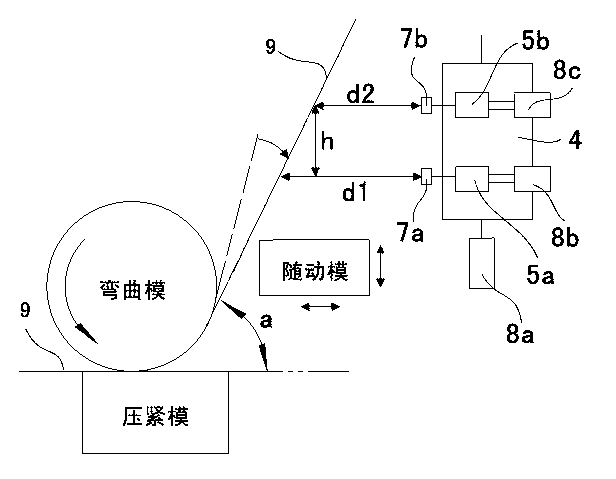

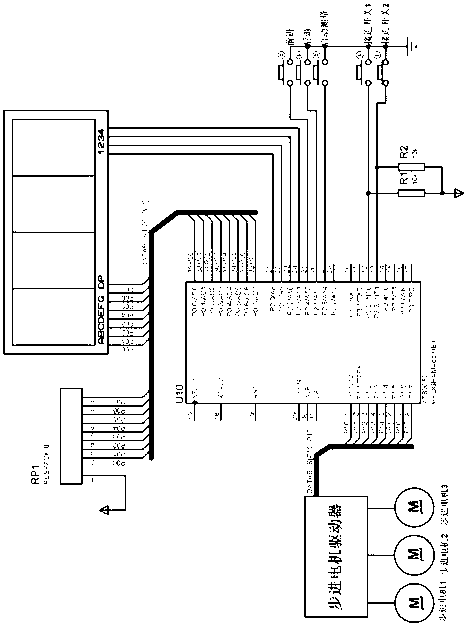

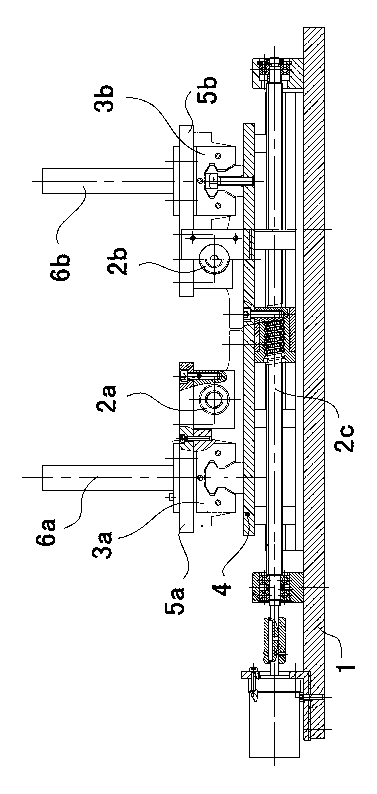

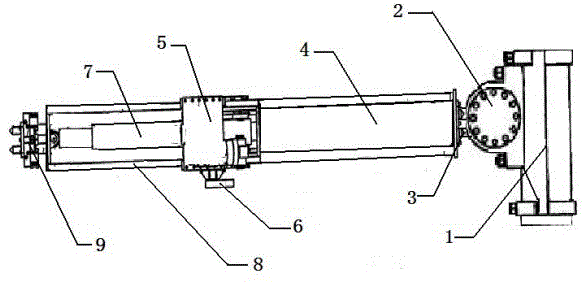

Method and device of elbow pipe angle detection

InactiveCN103063188AHigh precisionImprove efficiencyMeasurement devicesMeasurement deviceDisplay device

The invention discloses a method and a device of elbow pipe angle detection. The method of the elbow pipe angle detection includes the steps of arranging two sensors besides an included angle section of an elbow pipe, using stepping motors to drive the two sensors to respectively detect position information of two point locations, sending the position information to a single chip microcomputer, finishing calculation by the microcomputer and displaying angle information on a displayer. The device of the angle of the elbow pipe detection comprises a moving assembly, the sensors, the displayer, and the single chip microcomputer. The moving assembly comprises a group of moving platforms which are overlaid, the moving directions of the moving platforms are perpendicular to each other, the sensors are arranged on the moving platform arranged at the top portion, and the moving assembly, the sensors and the displayer are respectively connected with the single-chip microcomputer. The accurate angle of bend of the elbow pipe can be displayed on the displayer, precision of elbow pipe products is improved, and precision and efficiency of production of the elbow are improved.

Owner:HUNAN INSTITUTE OF ENGINEERING

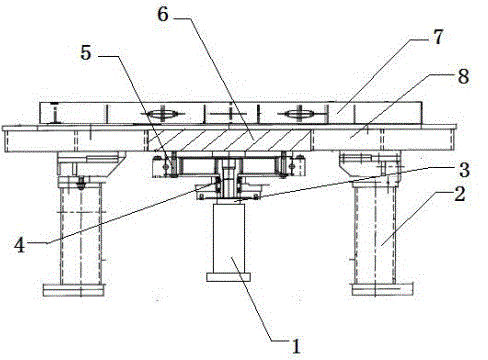

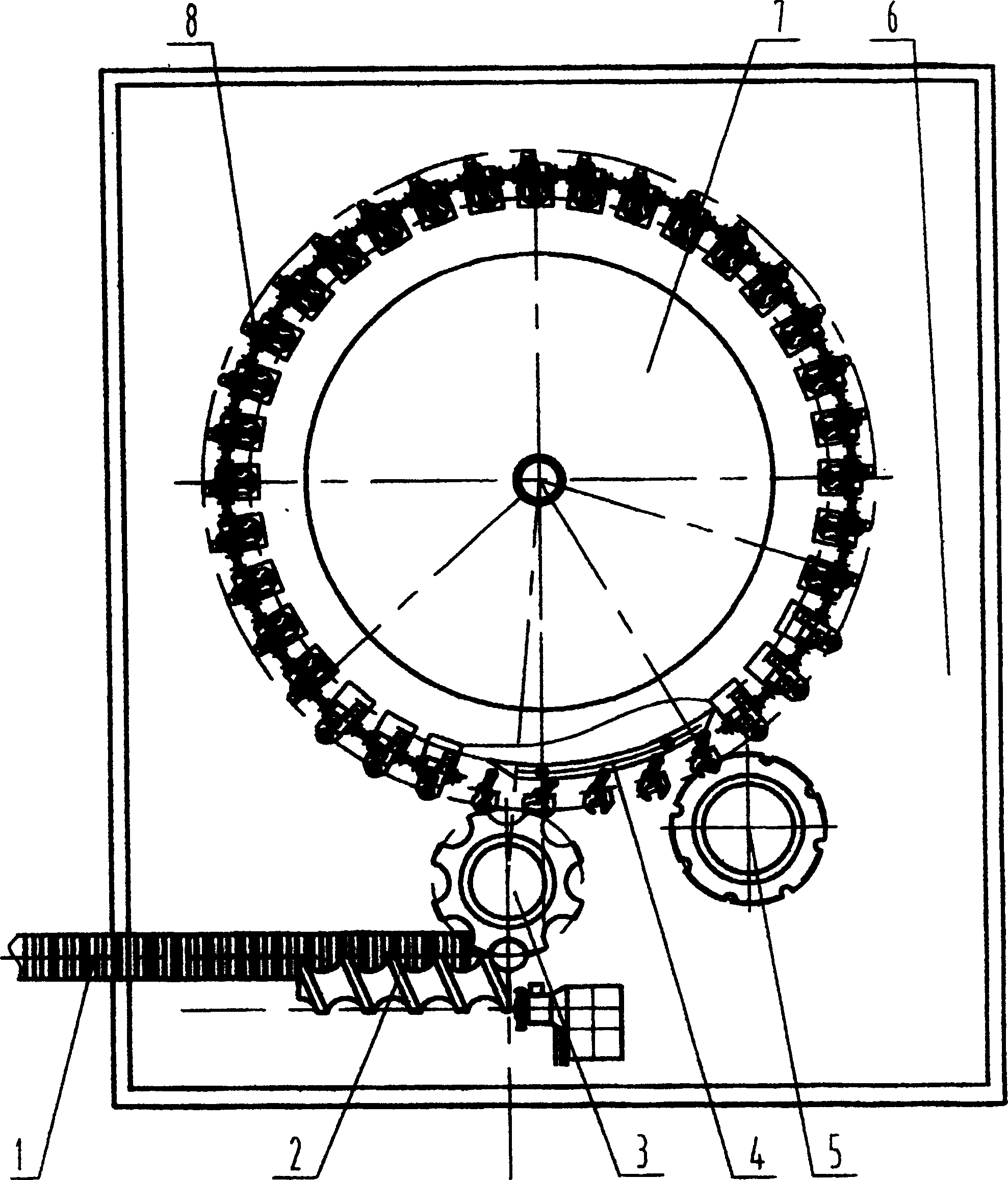

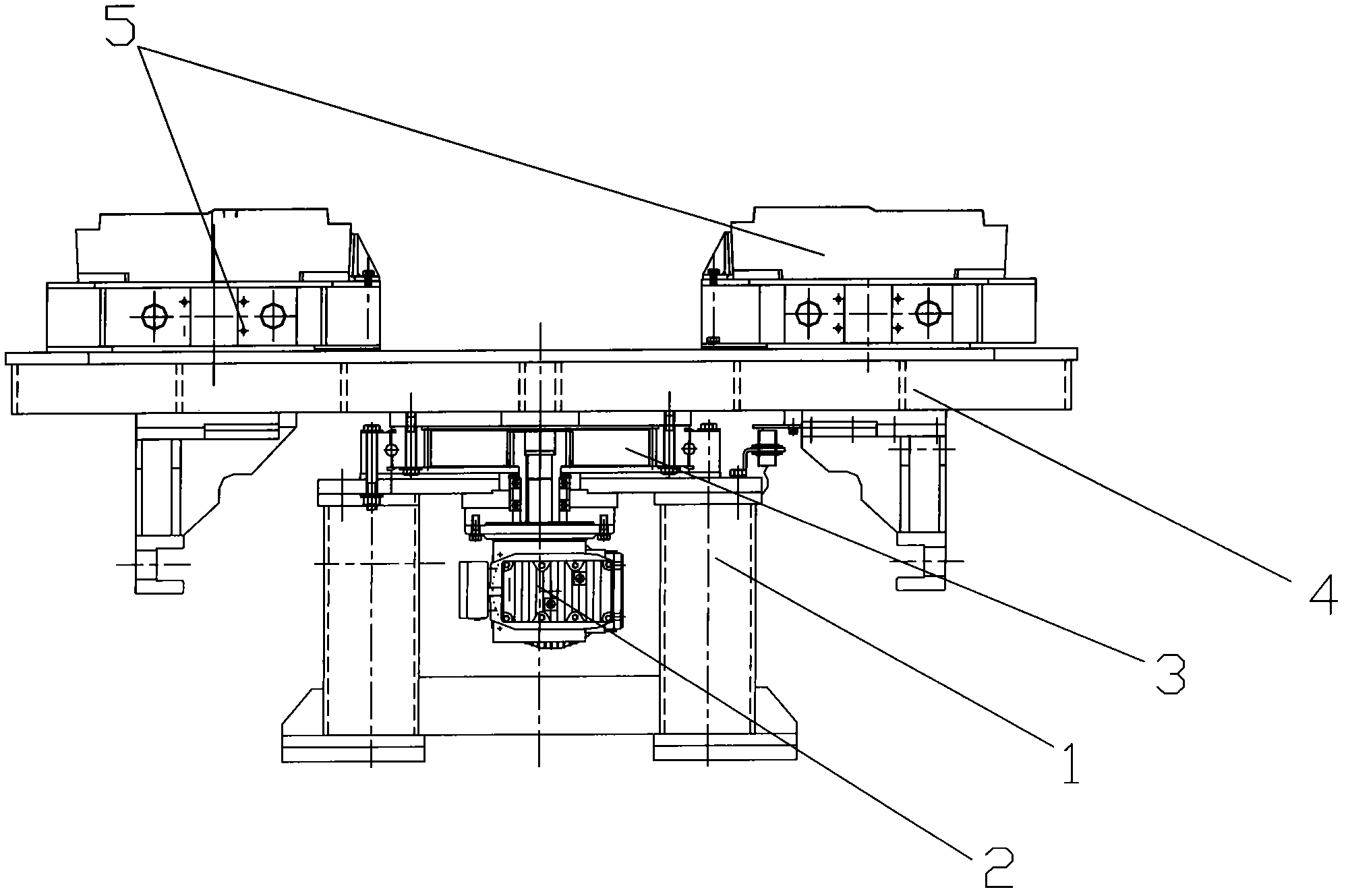

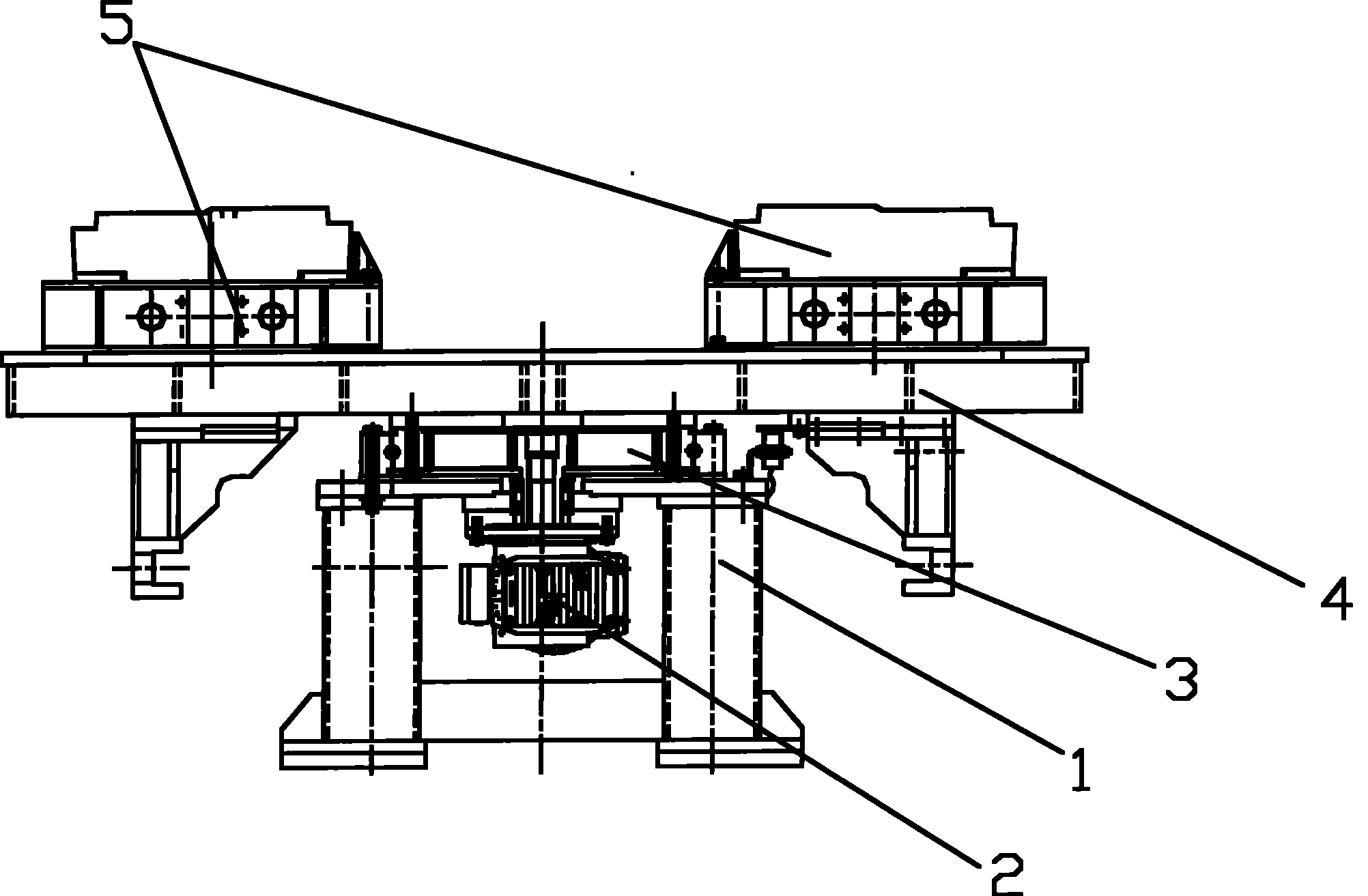

Automatic rotating mechanical worktable

InactiveCN105562629AImprove combination efficiencyGuaranteed rotation angleMould tablesHydraulic cylinderCoupling

An automatic rotating mechanical worktable is characterized by comprising a hydraulic cylinder, supporting stand columns, a hydraulic piston, a coupler, a fixing tool, a rotating disc, a worktable body and a fixing chuck, wherein the fixing chuck is fixed to the supporting stand columns, the worktable body is arranged on the fixing chuck and connected with the rotating disc arranged in the fixing chuck, the lower side of the rotating disc is connected with a driving device, the driving device comprises the hydraulic cylinder, the hydraulic piston and the coupler, the hydraulic piston of the hydraulic cylinder is connected with the coupler, the driving device is connected to the lower side of the rotating disc through the fixing tool, the rotating disc is in a round cake shape, a sliding wheel is arranged on the outer edge of the rotating disc, the fixing chuck is in a ring shape, and a sliding track matched with the sliding wheel of the rotating disc is arranged on the inner ring of the fixing chuck. The automatic rotating mechanical worktable has the advantages that the structure is simple, use is convenient, the combination efficiency of sand cores can be effectively improved, and the labor intensity of workers can be effectively relieved; besides, by adopting a tabletop rotating device, the rotating angle of the sand cores can be guaranteed, the sand cores can be prevented from being damaged, the rate of finished products can be increased, and requirements of modernized production can be met.

Owner:贾雪松

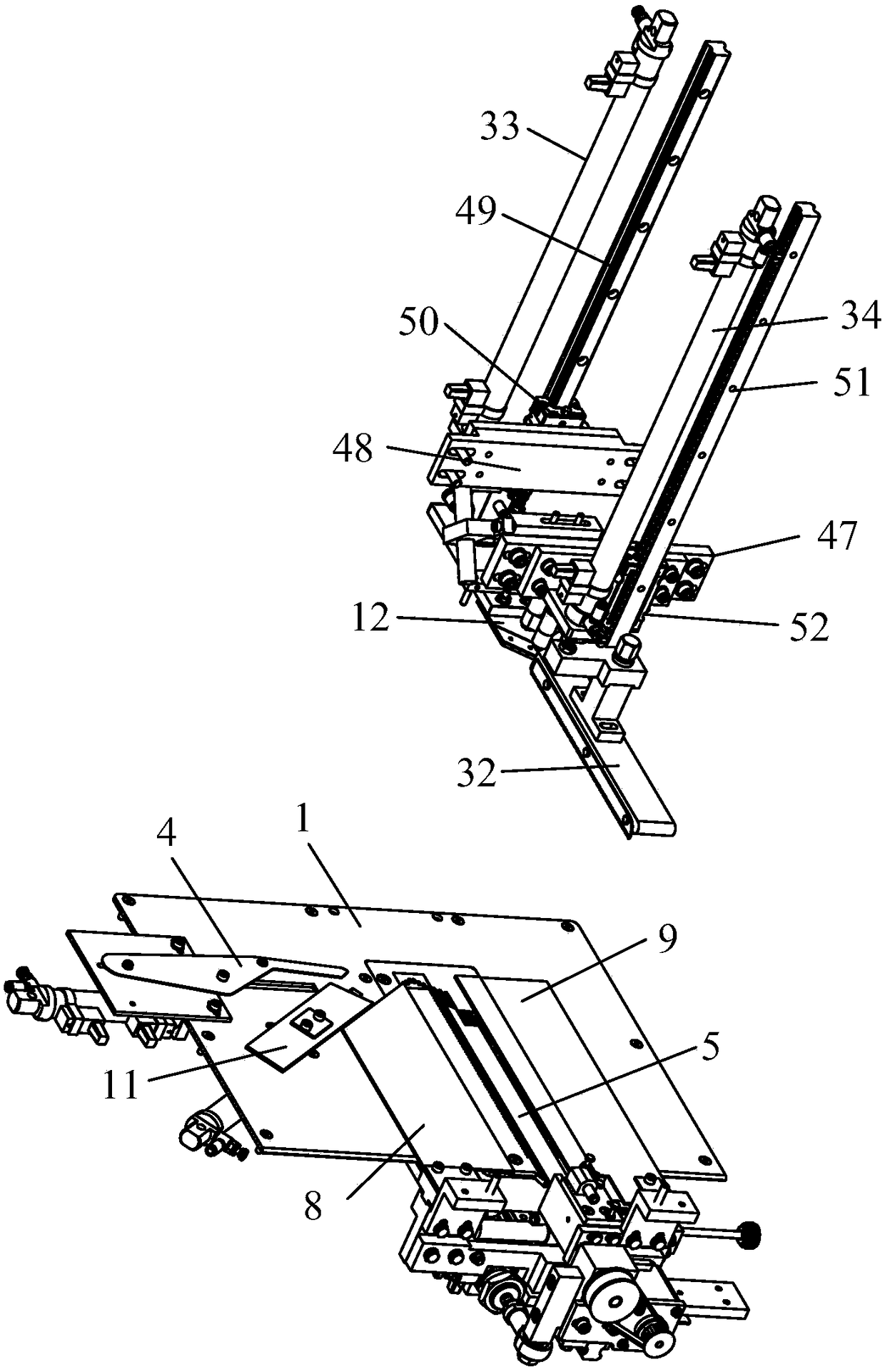

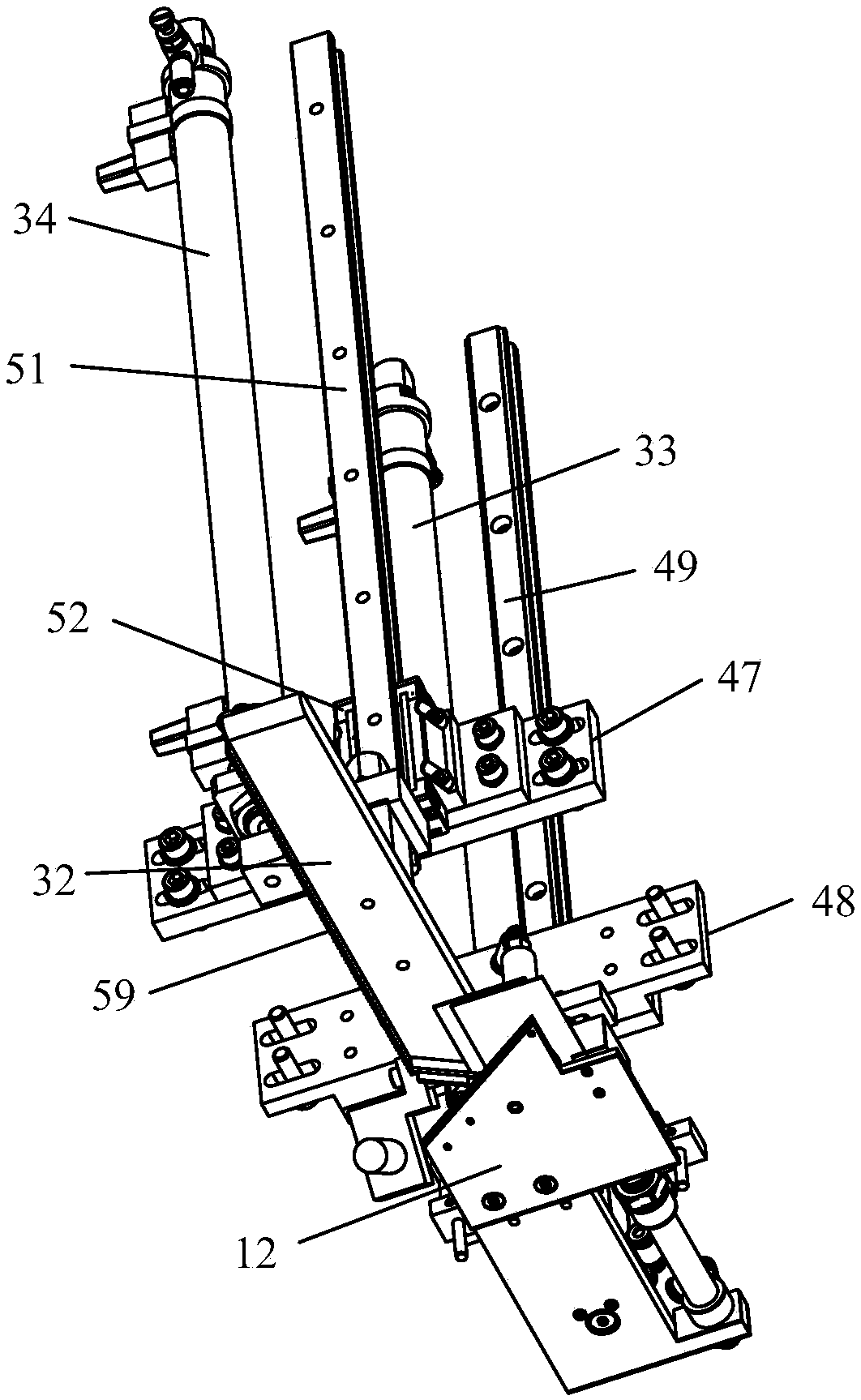

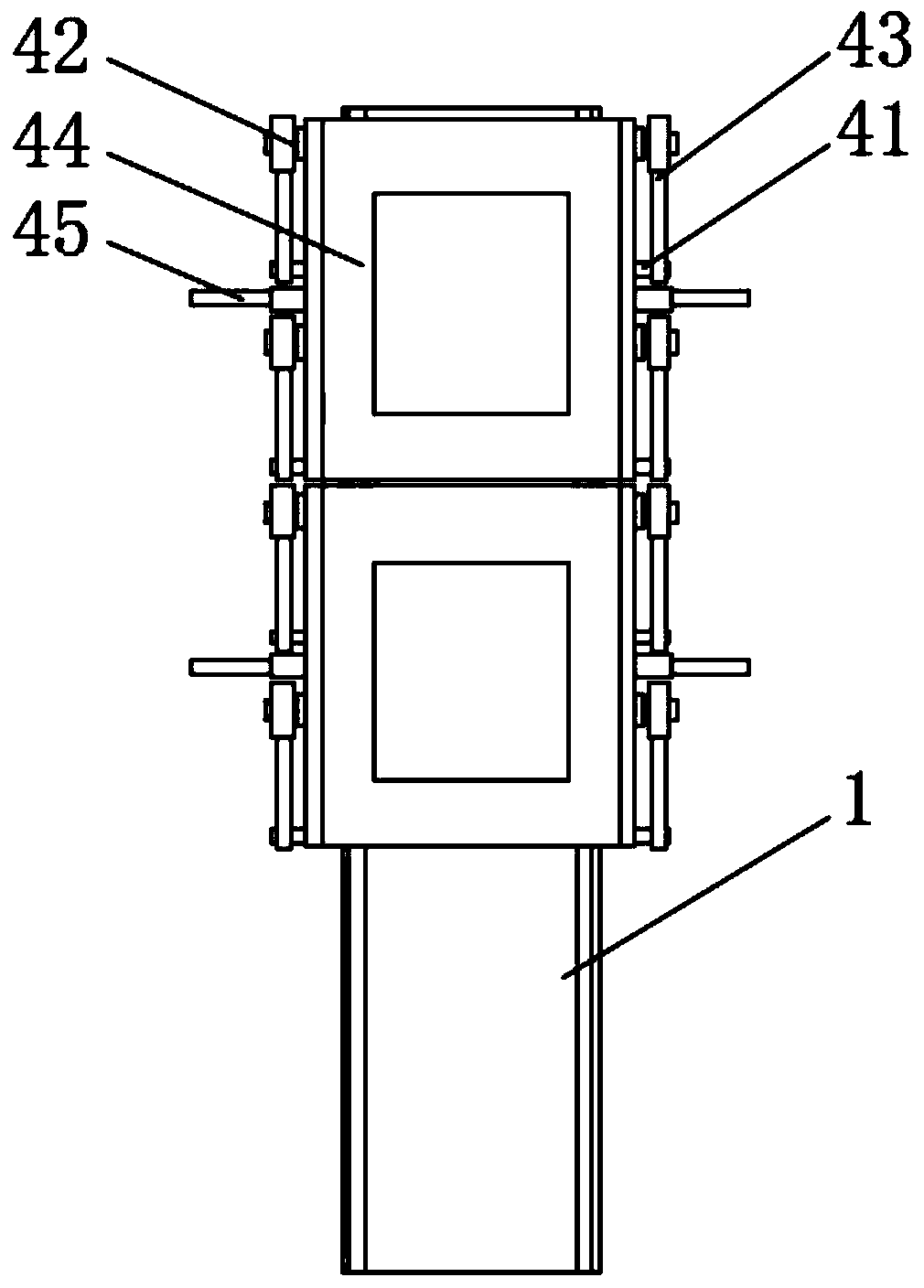

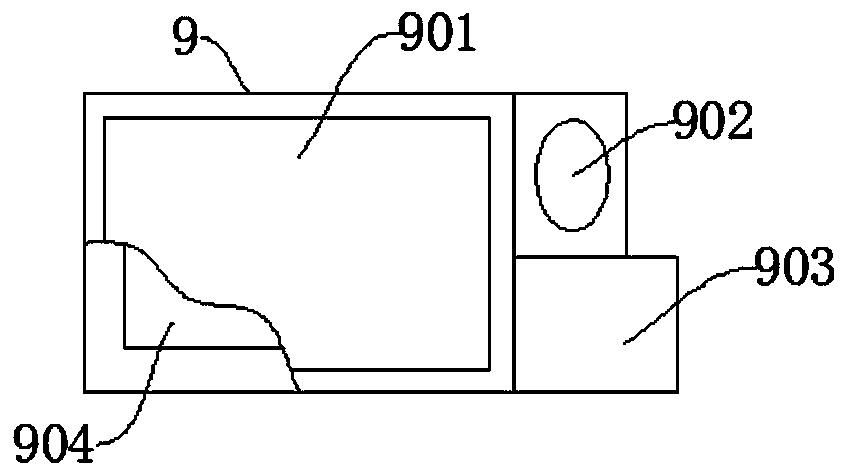

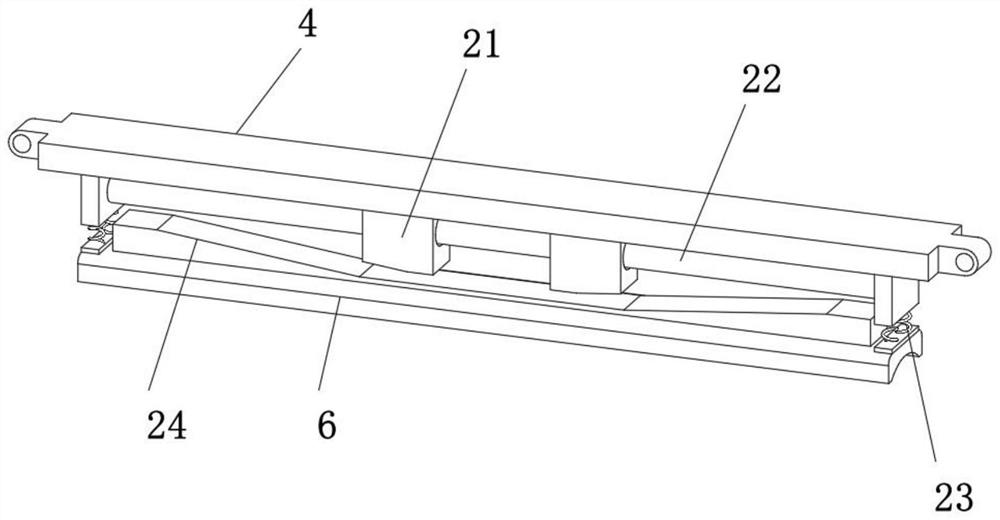

Automatic folding mechanism and method and sleeve placket sewing device

ActiveCN108505226AImprove folding efficiencyImprove fold qualityWork-feeding meansEngineeringMechanical engineering

The invention provides an automatic folding mechanism and method and a sleeve placket sewing device. The automatic folding mechanism comprises a fixing base plate, a discharging plate, a baffle assembly, a discharging cavity formed by the discharging plate and the baffle assembly, a turnover clamping assembly located in the discharging cavity and a fold material shifting piece. One end of the discharging cavity is provided with a sleeve placket end forming part, a plurality of first suction holes distributed in the peripheral direction of the discharging cavity at intervals are formed in the discharging plate, the clamping assembly comprises a movable clamping plate and a fixed clamping plate which are stacked, and a clamping cavity formed in the movable clamping plate and the fixed clamping plate, the movable clamping plate can move close to or away from the fixed clamping plate, the fold material shifting piece is located at the upper side of the baffle assembly and can move close toor away from the sleeve placket end forming part. The small cutting pieces and large cutting pieces are automatically folded into sleeve plackets, operators just need to place the small cutting pieces and the large cutting pieces, time and labor are saved during operation, and the cutting piece folding efficiency and quality are greatly improved.

Owner:JACK SEWING MASCH CO LTD

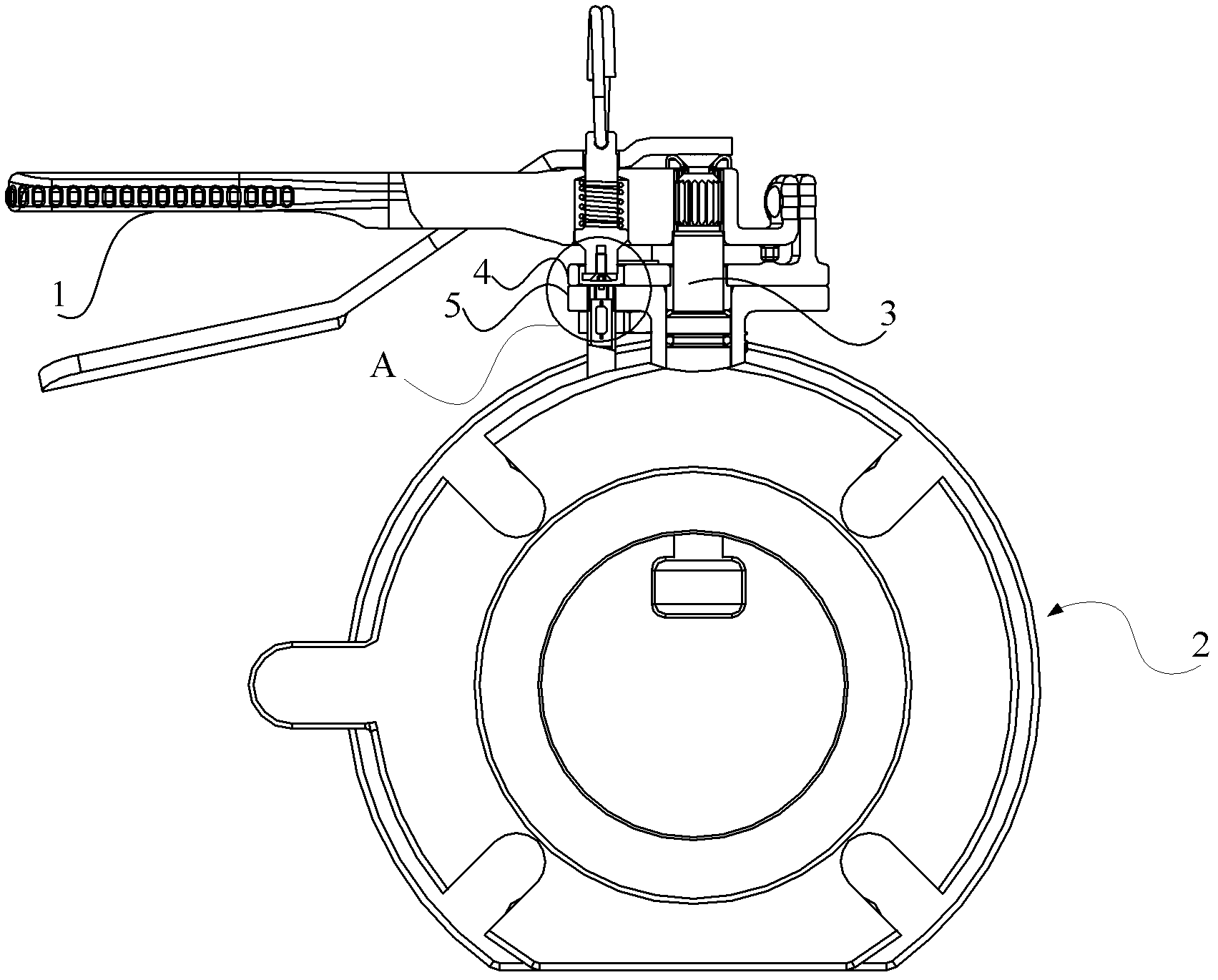

Valve

InactiveCN103216657AAutomatic detection of switch statusAvoid monitoringOperating means/releasing devices for valvesMobile endEngineering

The invention discloses a valve, which comprises a mobile end and a valve main body, wherein the mobile end is fixedly arranged on the valve main body and is used for controlling the opening and the closing of the valve through a valve operating control element, the valve is characterized in that a signal sending device is arranged on the mobile end and is used for sending an action signal, the valve main body is provided with a stationary end, a signal receiving device is arranged on the stationary end and is used for receiving the action signal, and the signal receiving device receives the action signal when the valve is closed. The opening and closing state of the valve can be automatically detected through the signal sending device and the signal receiving device, so that the valve with the advantages of accuracy, high speed, controllability and intelligence is provided, the opening and closing state of the valve is prevented from being operated and monitored manually, and the requirement of rapidly-developed modern production is met.

Owner:FORT VALE ENG SHANGHAI LTD +1

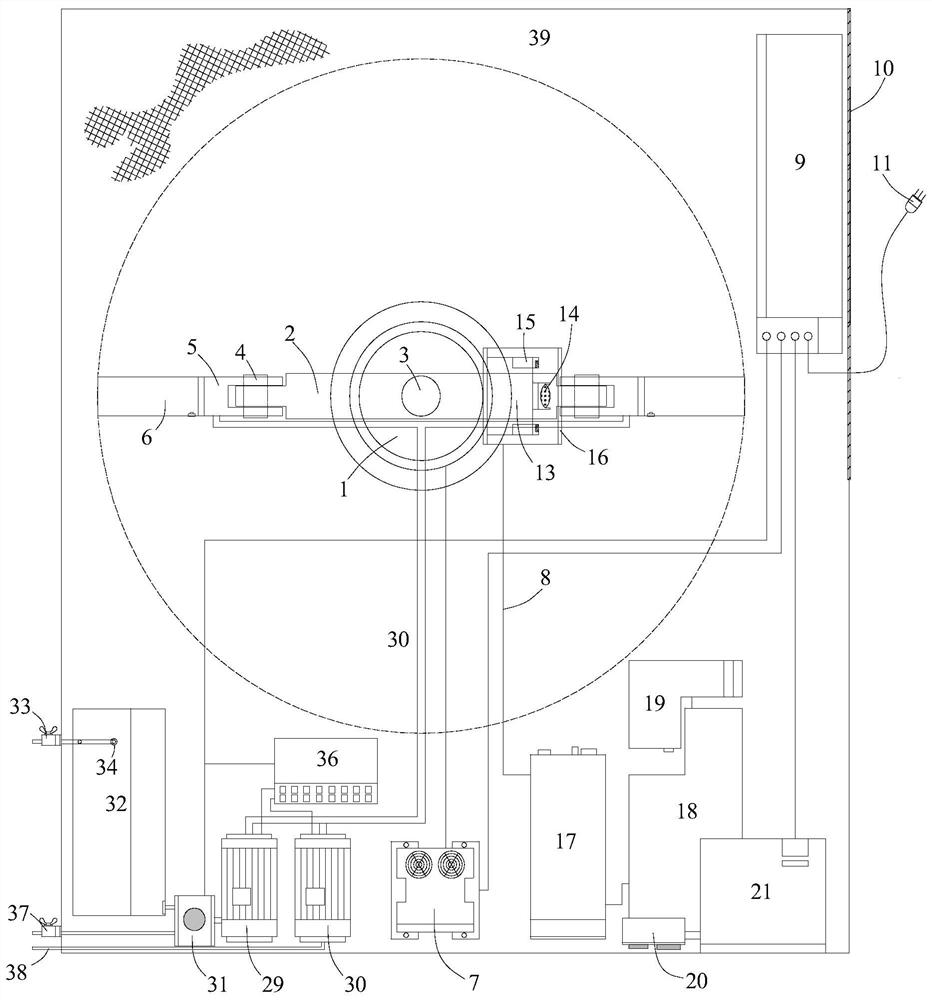

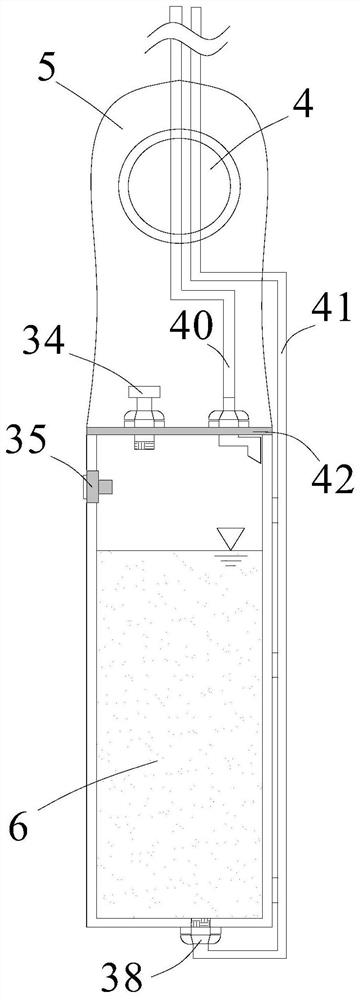

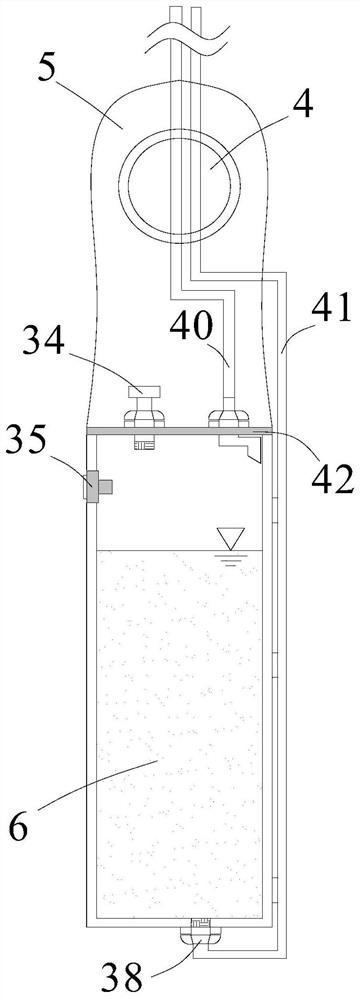

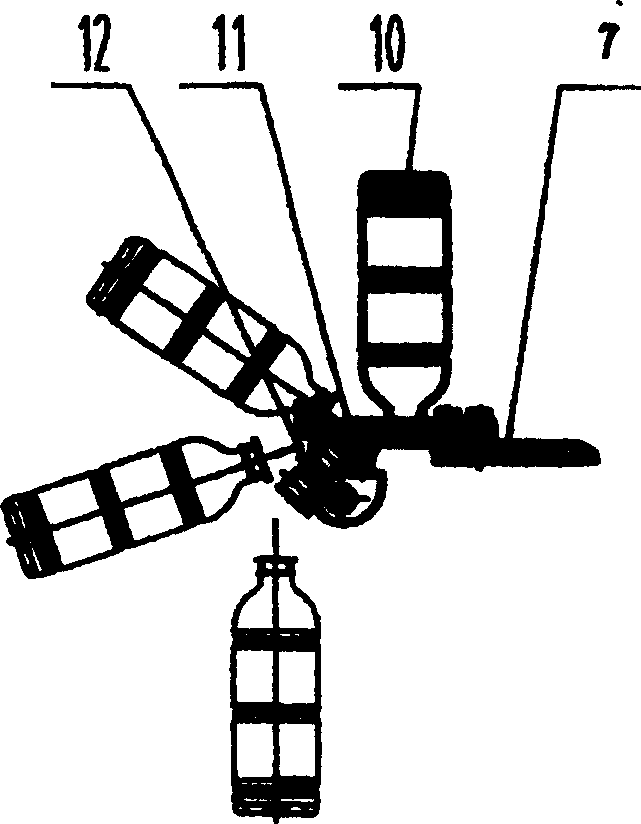

Machine vision suspension turbidity detection device and detection method

ActiveCN112964606AGuaranteed accuracyEnsure repeatabilityImage enhancementImage analysisComputer hardwareEngineering

The invention discloses a machine vision suspension turbidity detection device and a detection method. The machine vision suspension turbidity detection device comprises a suspension centrifugal separation module, a feeding, discharging and cleaning module and a machine vision and processing module, wherein the suspension liquid separation module comprises a motor, a centrifugal cantilever, a rotating head, a hanging basket and a sample detection chamber; the feeding, discharging and cleaning module comprises a water storage tank, an electromagnetic valve, a liquid level sensor, a feeding pipe and a discharging pipe; the machine vision and processing module comprises an industrial camera, a light source, an image acquisition card, an electronic computer and a PLC; and an optical filter is arranged between the light source and the sample detection chamber; and the image acquisition card is used for converting an image signal obtained by the industrial camera into a digital signal and transmitting the digital signal to a memory of the electronic computer for processing. The machine vision suspension turbidity detection device is high in detection precision and reliability.

Owner:CENT SOUTH UNIV

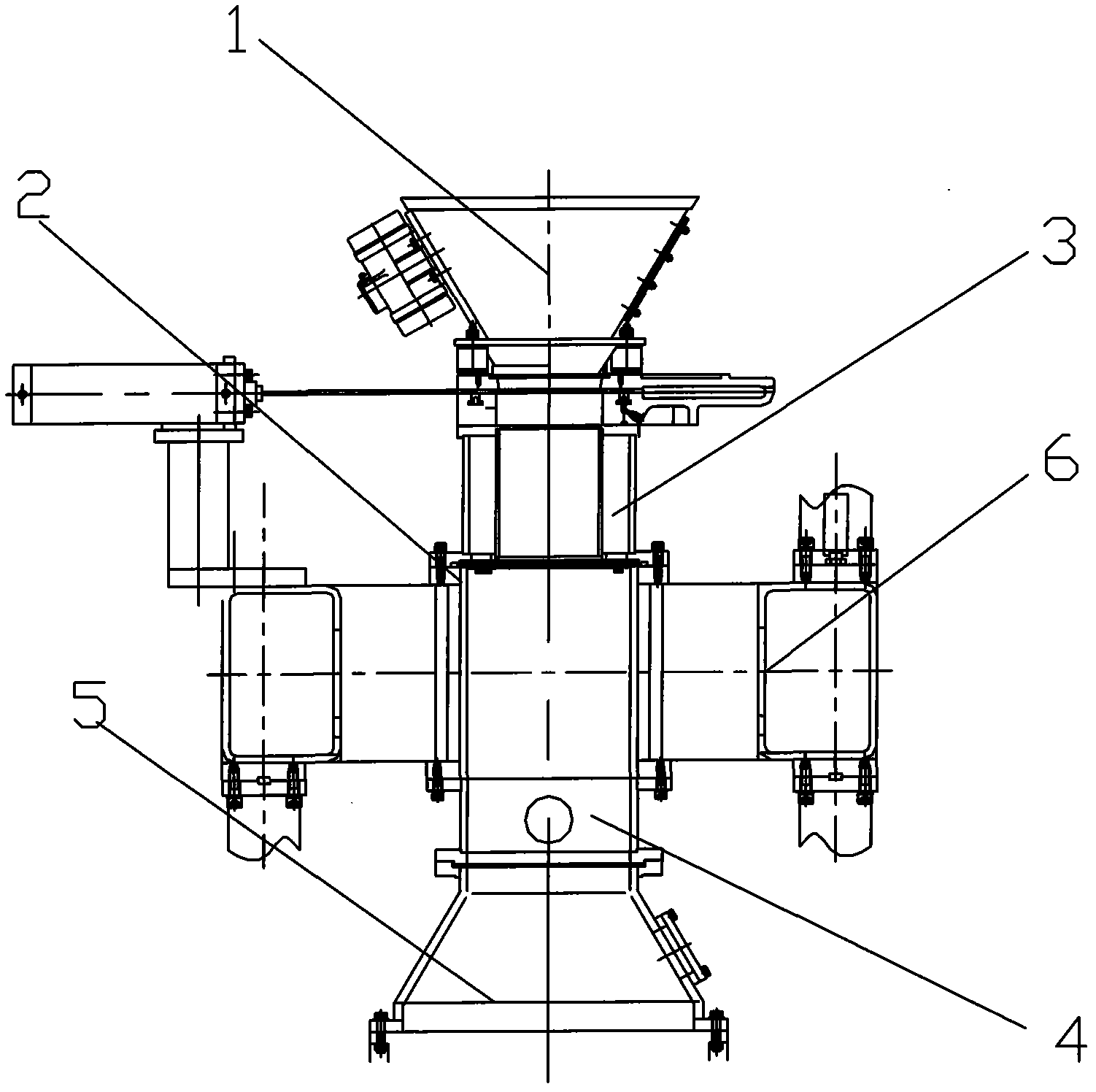

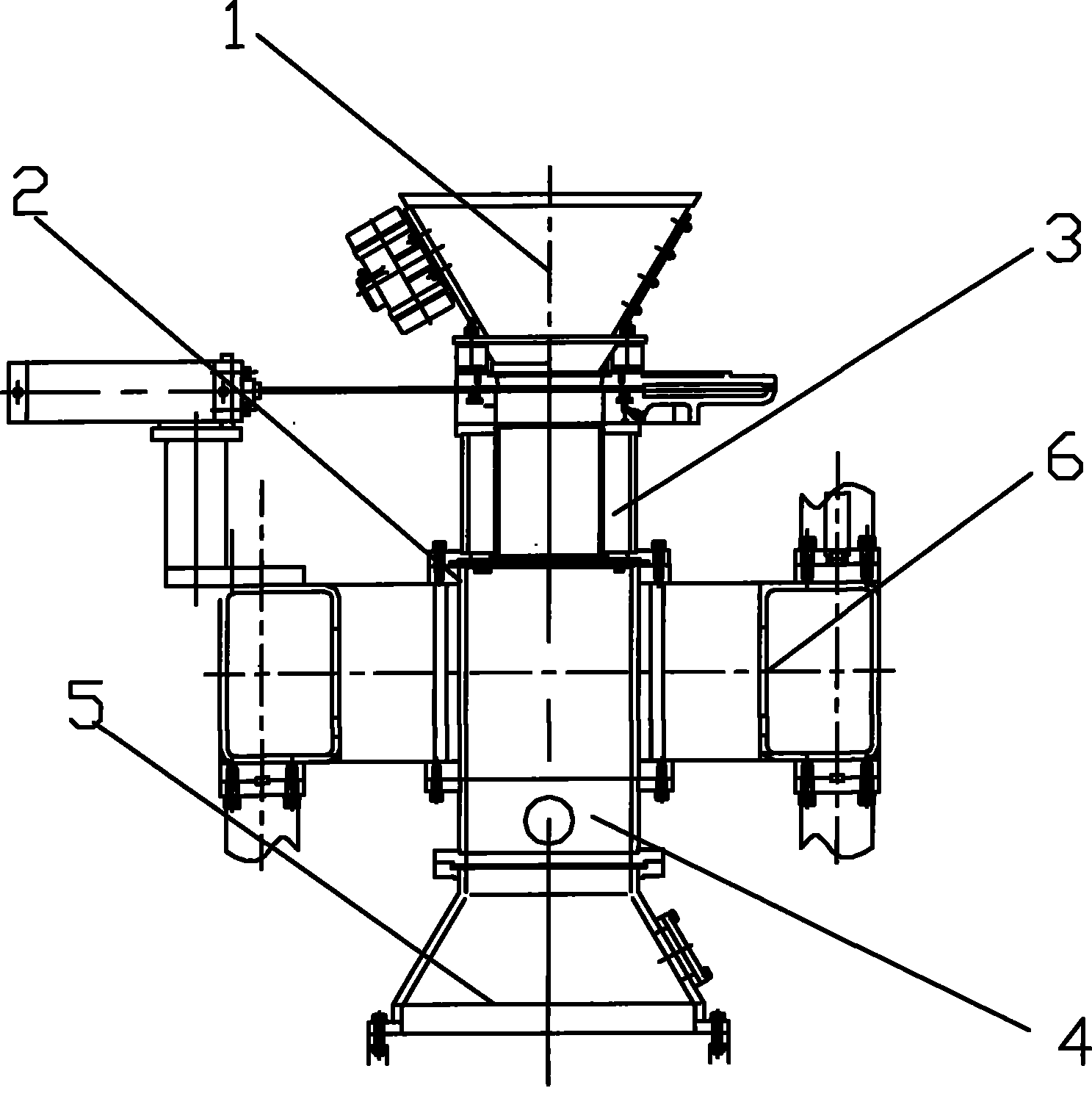

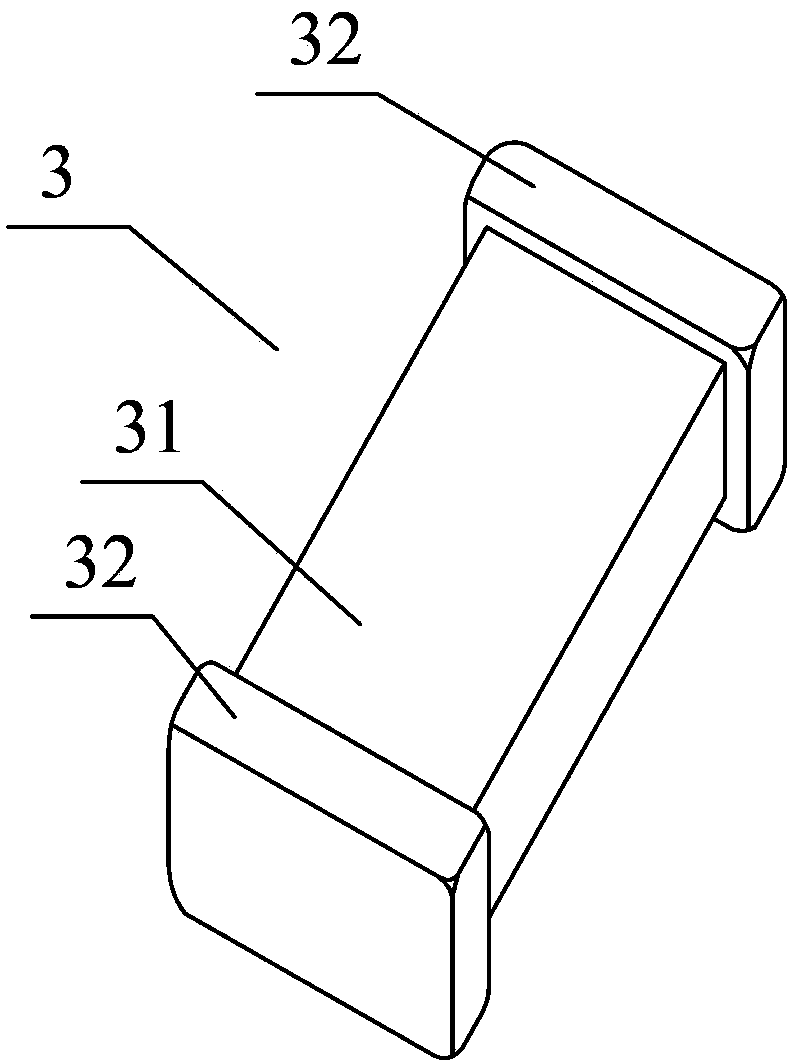

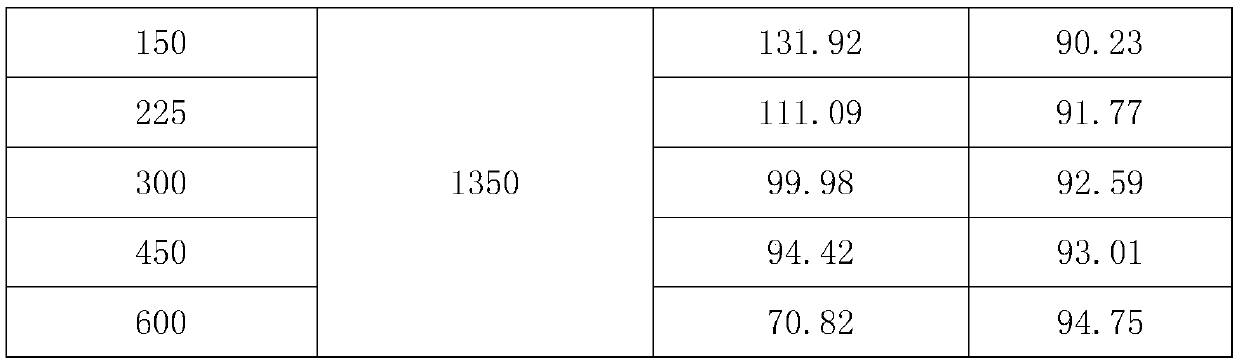

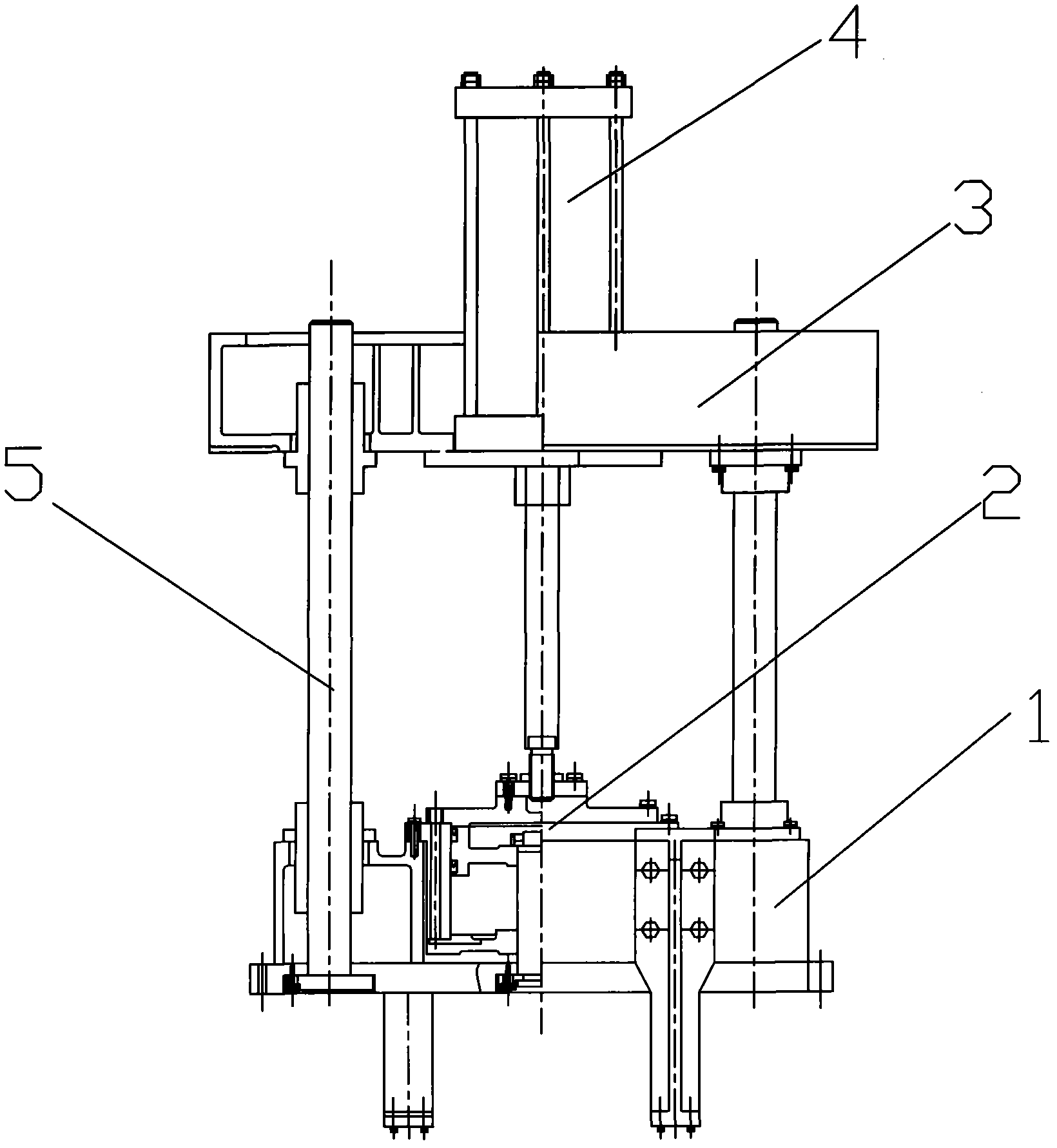

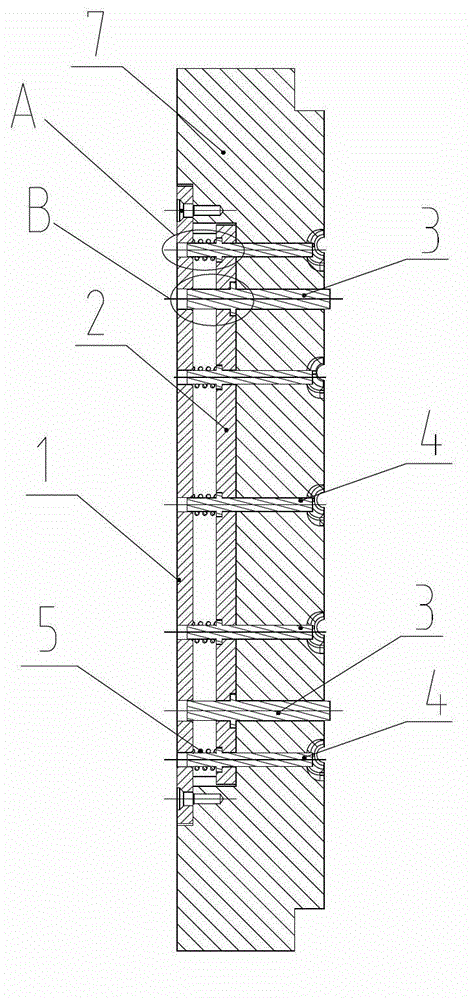

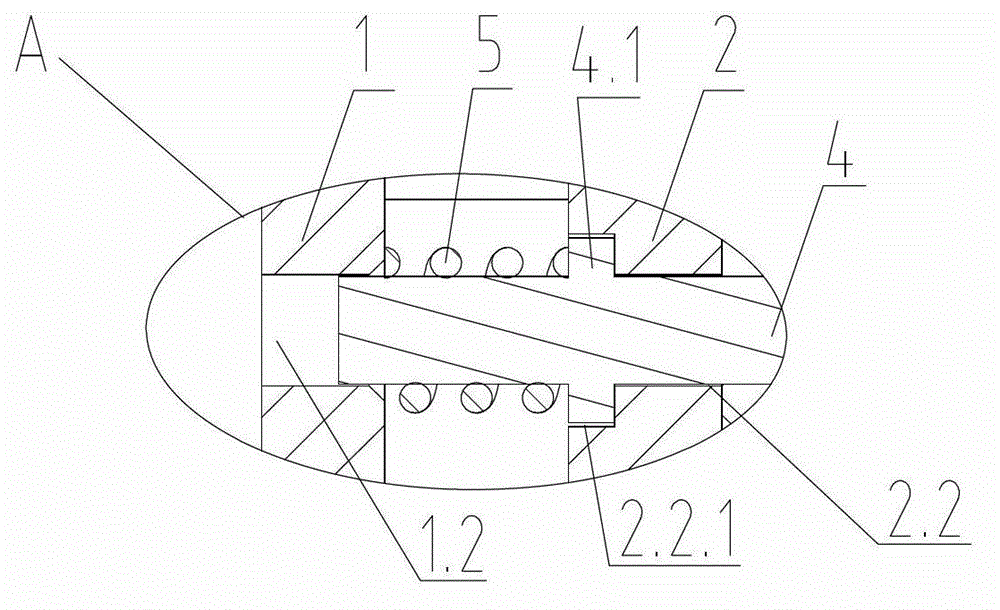

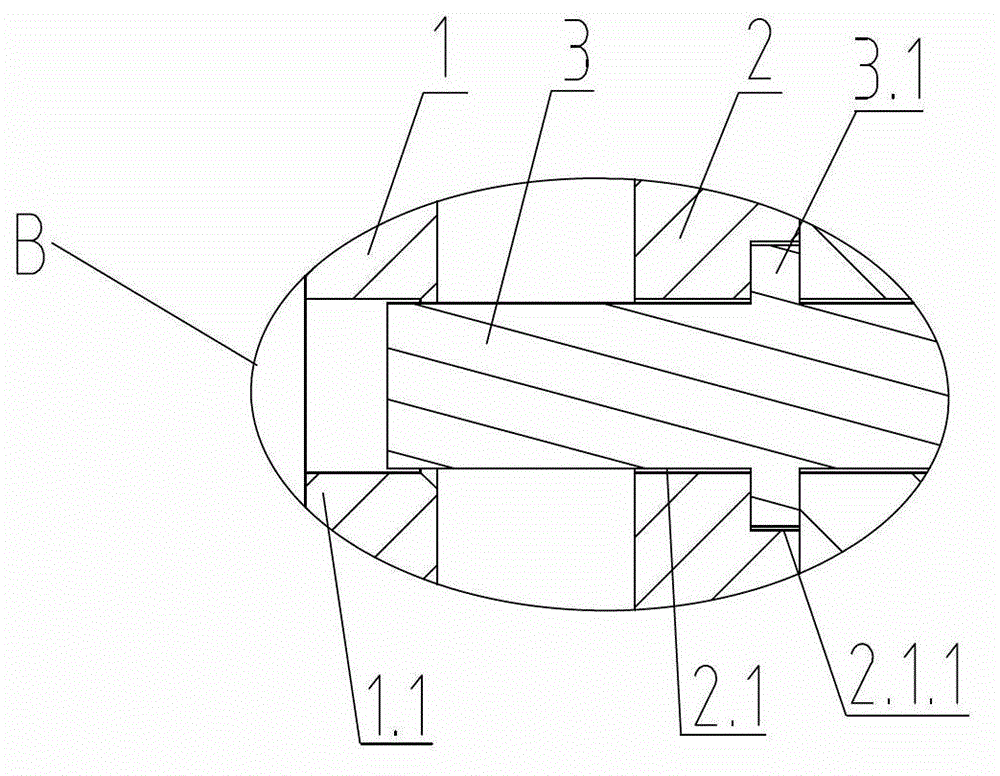

Automatic core ejecting device of core making machine

The invention belongs to the technical field of tooling design in foundry enterprises, and mainly relates to an automatic core ejecting device of a core making machine. The automatic core ejecting device comprises a press plate and a core ejecting plate, which are arranged in parallel, wherein the press plate is provided with at least two first return guide rod holes and at least one first core ejecting rod hole, the core ejecting plate is provided with second return guide rod holes corresponding to the first return guide rod holes, and further provided with a second core ejecting rod hole corresponding to the first core ejecting rod hole, return guide rods are arranged in the first return guide rod holes and the second return guide rod holes, core ejecting rods are arranged in the first core ejecting rod hole and the second core ejecting rod hole, compression bosses are arranged on the return guide rods, return bosses are arranged on the core ejecting rods and located on one side of the core ejecting plate, the compression bosses are located on the other side of the core ejecting plate, and a spring is mounted on one end of each core ejecting rod in a sleeving manner and compressed between each return boss and the press plate. The automatic core ejecting device of the core making machine has the advantages that the core ejecting device is prevented from being independently arranged outside a core box of the core making machine, the die space is saved, and the production cost is reduced.

Owner:DONGFENG AUTOMOBILE COMPANY

A machine vision suspension turbidity detection device and detection method

ActiveCN112964606BGuaranteed accuracyEnsure repeatabilityImage enhancementImage analysisComputer hardwareWater storage tank

The invention discloses a machine vision suspension turbidity detection device and a detection method. The detection device includes a suspension centrifugal separation module, a feed and discharge and cleaning module, and a machine vision and processing module; the suspension separation module includes a motor, a centrifugal cantilever, a rotor, a hanging basket and a sample detection chamber; the feed and discharge The material and cleaning module includes a water storage tank, a solenoid valve, a liquid level sensor, a feed pipe and a discharge pipe; the machine vision and processing module includes an industrial camera, a light source, an image acquisition card, an electronic computer, and a PLC controller; the light source A filter is installed between the sample detection chamber and the image acquisition card is used to convert the image signal obtained by the industrial camera into a digital signal and transmit it to the electronic computer memory for processing. The detection device of the invention has high detection accuracy and reliability.

Owner:CENT SOUTH UNIV

Production method of matcha-flavored meatballs

The invention relates to a production method of matcha-flavored meatballs. The production method comprises operation steps as follows: 1, raw material meat is cleaned and cut into strips; 2, a pickling liquid is produced and meat strips are pickled; 3, the pickled meat strips are fully rolled and rolled meat strips are obtained; 4, the rolled meat strips are cut into pieces, cleaned, cooked thoroughly in water and minced, and meat paste is obtained; 5, clear water, soybean protein powder and starch are added to the meat paste, the mixture is stirred, and stuffing is obtained; 6, round meatballs in uniform size are kneaded with a conventional method and cooked, and the matcha-flavored meatballs are obtained. The matcha-flavored meatballs have the color scale higher than 1.3 b / a and the shear force value higher than 0.550 kg*f. Fresh tea and pork are adopted in the process method, so that the matcha-flavored meatballs have better eating safety and have a new flavor.

Owner:ANHUI AGRICULTURAL UNIVERSITY

Device capable of automatically adjusting strip steel tension

PendingCN107585616AStable tensionImprove production accuracyArticle deliveryWebs handlingControl systemStrip steel

The invention provides a device capable of automatically adjusting strip steel tension. The device comprises an input speed regulation mechanism, an output speed regulation mechanism and a tension adjustment mechanism, the input speed regulation mechanism is arranged at the input end of a heating furnace, and the input speed regulation mechanism controls the speed of strip steel for entering the heating furnace; the output speed regulation mechanism is arranged at the output end of an annealing furnace, the output speed regulation mechanism controls the speed of the strip steel for moving outof the annealing furnace, and the tension adjustment mechanism comprises a fixed roller; a bounce roller which drives the strip steel to move in an S-shaped mode is arranged aslant above the fixed roller, the bounce roller is close to one end of the heating furnace, and a balancing weight is arranged on the bounce roller; a tension sensor is arranged on the balancing weight, and the tension sensor, the input speed regulation mechanism and the output speed regulation mechanism are electrically connected with a control system. The device capable of automatically adjusting strip steel tension measures the tension of the strip steel easily and conveniently, sends signals, automatically controls the adjustment tension within the proper range, does not need manual monitoring, saves labor cost, and improves the precision and production efficiency of the strip steel.

Owner:TIANJIN YU RUN DE METAL PROD

LED (Light Emitting Diode) ageing detection screening equipment and method

ActiveCN102172580BExtend detection timeImprove detection efficiencySortingIndividual semiconductor device testingControl systemPower apparatus

The invention discloses LED (Light Emitting Diode) ageing detection screening equipment and method. In the equipment, a push rod is driven by a power device to make each splint press towards a corresponding LED row and a corresponding LED cathode pin is in contact with a corresponding cathode contact, so that electrification of LEDs is realized; meanwhile, detection screening of the LEDs is realized by using a PC (Personal Computer) machine. In the entire ageing process, rated voltage output by a circuit control system is kept at 24V, the rated current output is 50mA, current and voltage input to the LEDs are adjustable, and the rated current and rated voltage are supplied to the ageing of the LEDs for 20-60 minutes; through ageing, LEDs with electrical and process hidden troubles can be eliminated; and after ageing, the power device stops acting on the push rod and each splint returns to an initial position under the action of the acting force of a return spring, so that detection of LEDs is realized and defective LEDs are eliminated.

Owner:JIANGMEN JIANGHAI DISTRICT KAIHUI PHOTOELECTRIC EQUIP CO LTD

Plastic bottle washing machine

InactiveCN1286585CCompact designSimple structural designHollow article cleaningDrive wheelEngineering

The present invention relates to a plastic bottle washing machine. It is characterized by that it includes bottle-feeding bottle-conveying guideway, bottle-feeding auger component, bottle-feeding driving wheel component, manipulator open-close component, machine frame component, rotating component, mechanical arm turning component, and following flushing component. Said invention also provides their connection relationship. Said invention can be extensively used in the pharmaceutical and food machinery fields, and its washing effect is good.

Owner:TRUKING TECH LTD

Positioning device for welding semiconductor parts

ActiveCN110773932ARealize the handling processGuaranteed machining accuracyWelding/cutting auxillary devicesAuxillary welding devicesDevice materialGear wheel

The invention discloses a positioning device for welding semiconductor parts. The positioning device comprises a feeding table, extension plates, a translation mechanism, a feeding and discharging mechanism, a limit mechanism and an adsorption mechanism, the outer side of the feeding table is provided with a through groove, the both sides of the feeding table are correspondingly and fixedly connected with the extension plates, the middle part of the feeding table is provided with the limit mechanism, the translation mechanism comprises track racks, guard plates, a connecting plate, a first servo motor, a driving rod, a driving gear and a shift fork, the track racks are fixedly connected on the upper sides of the extension plates, the upper sides of the track racks are correspondingly provided with the guard plates, the connecting plate and the driving rod are arranged between the two guard plates, and the connecting plate and the guard plates are fixedly connected. According to the positioning device, the structure is compact,with the characteristics of reasonable structural design and high degree of automation, the translation mechanism can stir a horizontal cover plate in the feeding and discharging mechanism to move back and forth when being specifically used, the feeding and discharging mechanism, cooperating with the adsorption mechanism, can realize the carrying process of the semiconductor devices, and the limit mechanism can accurately positioning the semiconductor parts from four directions.

Owner:WENZHOU UNIVERSITY

Process for preserving instant hot pickled mustard tuber

InactiveCN1820640AGuaranteed crispnessImproved quality and tasteFood preservationFood preparationPlant TubersHigh oxygen

The present invention relates to one process of producing instant hot pickled mustard tuber. During the production process, the hot pickled mustard tuber after processing is first nitrogen-filling packed and then sterilized and cooled. The nitrogen-filling packing is super to available packing mode, which has relatively high oxygen residue, easy product oxidation, inhomogeneous supplementary material dispersing and more deformation of hot pickled mustard tuber. The filled nitrogen amount is controlled, so that the hot pickled mustard tuber may be sterilized through spraying and water bath for effective sterilization and maintaining product crispness. The technological process can raise the quality of instant hot pickled mustard tuber.

Owner:CHONGQING FULING ZHACAI GROUP

Flexibility detection system and method of circuit board

InactiveCN102736019BRealize automated detectionReduce labor intensityElectronic circuit testingSystem developmentElectrical and Electronics engineering

The invention provides a flexibility detection system of a circuit board. The flexibility detection system is connected with an upper computer and a detection module through an RS232 bus, automatically detects the circuit board through a detection module, can transmit a detection result to the upper computer to display in real time, and can simultaneously detect various circuit boards. By aiming to the difference of detection conversion time of the various circuit boards, the flexibility detection system puts forward a scheduling method of improving priority through classification inversion, automatically regulates the priority of occupied bus and reasonably allocates the time of the occupied bus. The flexibility detection system of the circuit board can realize the automatic detection on the circuit board, especially is suitable for low-cost detection of small-batch various circuit boards, can effectively improve the detection precision, reduces the labor intensity of workers, reduces the cost and the development difficulty of a system, and meets the requirements in modernization production.

Owner:NINGBO UNIVERSITY OF TECHNOLOGY

Table top rotating device

The invention discloses a table top rotating device. The rotating device comprises a fixing support which is equipped with a drive motor, wherein the drive motor is connected with a working table for holding a sand core through a transmission mechanism. When the table top rotating device is in use, a sand core seat equipped with the sand core is placed on the working table, and the drive motor drives the working table to rotate an angle through the transmission mechanism, and correspondingly, the sand core rotates a certain angle. The table top rotating device has simple structure and is convenient to use; and by utilizing the device, combination efficiency of the sand core can be effectively improved, labor strength of a worker is lowered, rotation angle of the sand core is ensured, damage to the sand core is avoided, finished product ratio is improved, and the requirements of modernized production is met.

Owner:SUZHOU SUZHU FOUNDRY MACHINERY MFG

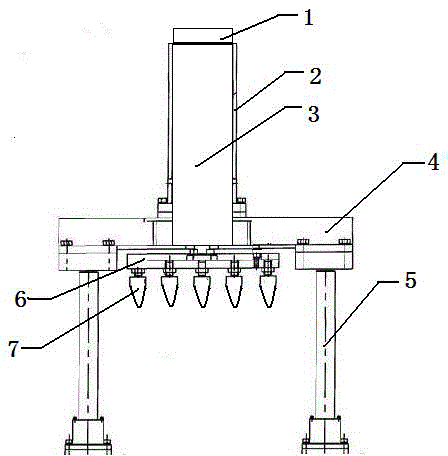

Novel pneumatic-type mold extraction device

InactiveCN105562612ASimple structureEasy to useFoundry mouldsMoulding machine componentsPneumatic cylinderPneumatic pressure

The invention discloses a novel pneumatic-type mold extraction device. The novel pneumatic-type mold extraction device is characterized in that the novel pneumatic-type mold extraction device comprises a piston head, a pneumatic cylinder, a piston rod, an installing frame, stand columns, a support frame and mold extraction members, the installing frame is provided with the pneumatic cylinder, the upper end of the pneumatic cylinder is the piston head, the piston rod of the pneumatic cylinder is connected to the support frame, the support frame is provided with the n mold extraction members and two sides of the installing frame are symmetrically provided with the stand columns for supporting. The novel pneumatic-type mold extraction device has a simple structure, is convenient for use, is suitable for core box periphery mold unloading, has high work efficiency, realizes automation, is free of manual operation, saves labor and a cost, reduces personnel labor intensity and satisfies modernized production requirements.

Owner:郑德娟

an automatic sewing machine

ActiveCN107475909BKeep tidy and organizedRealize fully automatic sewingProgramme-controlled sewing machinesWork-feeding meansIndustrial engineeringFully automated

The invention provides automatic sewing equipment. The automatic sewing equipment is provided with a rack, a sewing unit, a discharging unit, a sewing material separating unit, a sewing material clamping unit, a sewing material moving unit and a collecting unit. After an operating worker places a pile of cutting pieces (multiple pieces of sewing material vertically stacked) to be sewed on a cloth placing platform, subsequently a piece of sewing material on the top layer on the cloth placing platform is separated out by the sewing material separating unit, the separated sewing material is clamped by the sewing material clamping unit and transferred to a platform plate, the sewing material on the platform plate is transferred to a sewing machine by the sewing material moving unit, the sewing material is sewed by the sewing machine, and the sewed sewing material is supported by the collecting unit, so that full automatic sewing is achieved, it is only necessary for the operating worker to place a pile of cutting pieces on the cloth placing platform, the labor cost and the manpower cost are greatly reduced, it is effectively ensured that a sewing workshop of a clothing factory is clean and orderly, and the requirements of modern production are met.

Owner:JACK SEWING MASCH CO LTD

An automatic material return device and method

ActiveCN107350802BRealization of automatic material returnIncrease productivityAssembly machinesElectricityMaster controller

The invention discloses an automatic material return device and method, and relates to the technical field of recovery of workpieces. The automatic material return device comprises a rack, a master controller, a conveying belt and a driving mechanism; a plurality of material return operation machines are arranged on the periphery of the conveying belt, each material return operation machine comprises a touch screen, a sub-controller used for storing product information and material return reasons and a bar code printing device, and the sub-controllers are electrically connected with the master controller to transmit the product information and the material return reasons to the master controller; and a material return station is arranged at the tail end of the stroke of the conveying belt, and a display screen and a code scanning device which are connected with the master controller are arranged at the material return station for reading the product information and the material return reasons. According to the automatic material return device, components to be subject to material return are conveyed to the material return station through the conveying belt, automatic material return is achieved, the production efficiency is greatly improved, and the modernization production requirement is met; and the return components are stored in a classified manner through code scanning, the device and method are more scientific and efficient, the error rate is extremely low, classified collection is facilitated, and subsequent pertinence treatment is facilitated.

Owner:CHANGZHOU VOCATIONAL INST OF ENG

A feeding device for textile equipment

InactiveCN110127412BEasy to operateImplementation driveWebs handlingEngineeringMechanical engineering

The invention discloses a feeding device of textile equipment. The feeding device comprises a bottom plate, wherein a cloth winding roller is arranged on one side of the top of the bottom plate, and one end of the cloth winding roller is provided with a connecting pin in an embedded mode; and one end of the connecting pin is rotationally connected to a supporting pin through a pin shaft, the supporting pin is rotationally connected to the bottom plate through a supporting sleeve, the other end of the connecting pin is fixedly connected to a limiting shaft, and a threaded rod is arranged at thebottom of the limiting shaft. According to the feeding device of textile equipment, when the cloth winding roller needs to be disassembled or installed, a limiting hoop is driven to move through a rotating disc and the threaded rod, so that the limiting hoop is separated from the limiting shaft, then the cloth winding roller is inclined through lifting of the limiting shaft, and the cloth windingroller is pulled out; and if the installation is needed, the steps are operated in the reverse mode so that the cloth winding roller can be disassembled and installed, in the operation process, the rotating disc is controlled to limit the cloth winding roller, and the operation is simple and convenient.

Owner:安徽职业技术学院

Hole drilling tooling

The invention relates to a hole drilling tooling, which is characterized by comprising an installing seat, a motor output shaft, a connecting seat, a first oil cylinder, a connecting bearing, an oil opening, a second oil cylinder, a protection sleeve and a drill bit, wherein the device comprises a support device, a power mechanism and a feeding device; the support device is the installing seat; the motor output shaft is arranged on the installing seat in a sleeving way; one side of the motor output shaft is connected with a protection sleeve of the feeding device through a sliding connecting seat; the protection sleeve is made of high-hardness steel; the first oil cylinder and the second oil cylinder are arranged in the protection sleeve; the connecting bearing is arranged between the first oil cylinder and the second oil cylinder; the lower side of the connecting bearing is provided with the oil opening; and the front end of a telescopic rod of the second oil cylinder is in transmission connection with the drill bit arranged at the front of a sleeve. The hole drilling tooling has the advantages that the structure is ingenious; the production is safe; the positioning hole drilling is realized; the hole drilling tooling is applicable to continuously changed operation environment; the adaptive capacity is high; the applicability is high; the economic benefits are good; parts are made of high-hardness steel; the protection effect is good; the service life of the device is long; the complete mechanization of moving, ascending and descending is realized; the automation degree is high; and the modern production requirements are met.

Owner:宁焕

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com