A feeding device for textile equipment

A technology of feeding device and textile equipment, applied in thin material handling, transportation and packaging, winding strips, etc., can solve the problem that the drive and movement of the cloth winding roller cannot coexist, and achieve the effect of simple and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

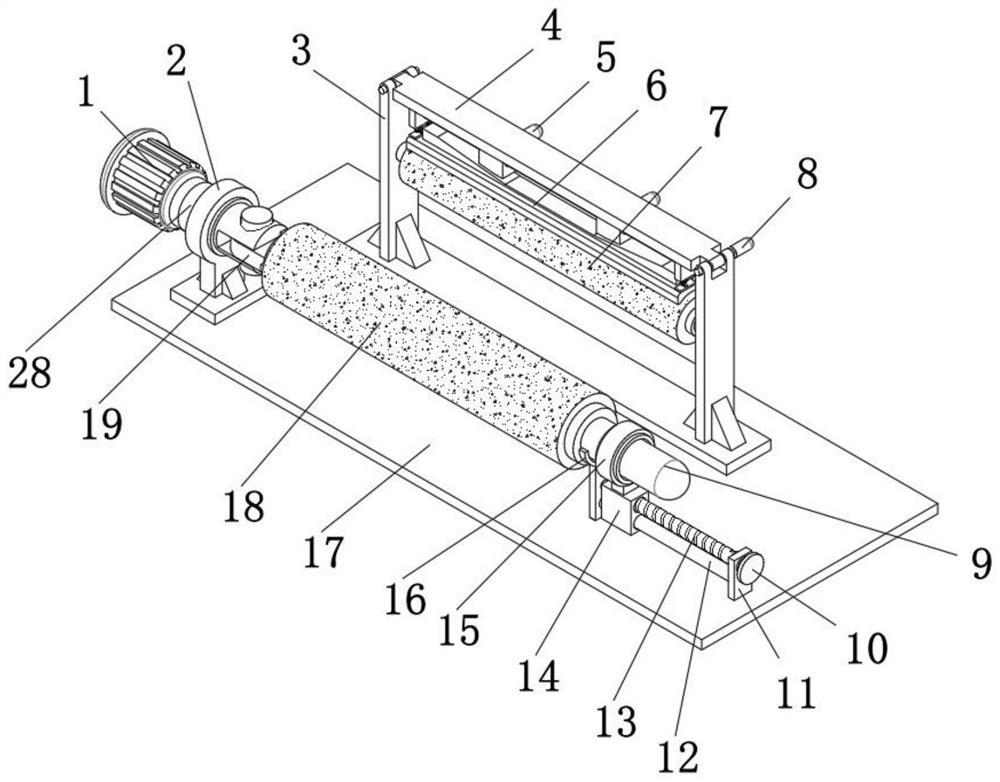

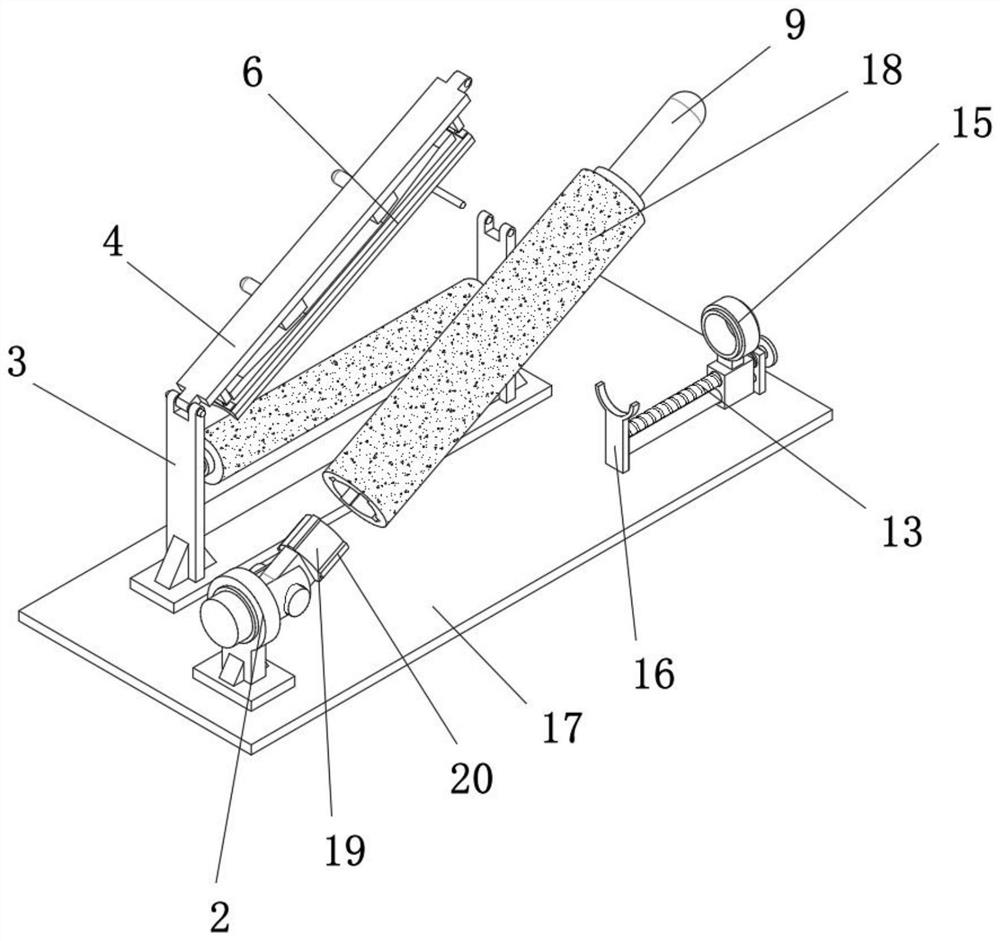

[0042] Example 1, please refer to figure 1 , figure 2 and Figure 4 , a feeding device for textile equipment, comprising a base plate 17, a cloth winding roller 18 is arranged on the top side of the bottom plate 17, a connecting pin 19 is embedded at one end of the cloth winding roller 18, and one end of the connecting pin 19 is rotated by a pin shaft Connected with a support pin 28, the connection pin 19 and the support pin 28 are perpendicular to each other, the support pin 28 can drive the connection pin 19 to rotate, and relative rotation can occur between the connection pin 19 and the support pin 28, wherein the support pin 28 is supported by The sleeve 2 is rotationally connected with the base plate 17, the support pin 28 is rotationally connected with the support sleeve 2 through a bearing sleeve, and the other end is fixedly connected with the limit shaft 9, and one end of the support pin 28 is transmission-connected with the output shaft of the drive motor 1, wherei...

Embodiment 2

[0043] Example 2, please refer to figure 1 and figure 2, the bottom of the limit shaft 9 is provided with a threaded rod 13, one end of the threaded rod 13 is rotatably connected to the clamping plate 16 through a rotating shaft, relative rotation can occur between the threaded rod 13 and the clamping plate 16, and the other end runs through the fixing plate 11, And the extension end is fixedly connected with the turntable 10, the operator drives the threaded rod 13 to rotate by turning the turntable 10, the top of the clamping plate 16 has a semi-circular arc structure, and the semi-arc structure realizes the function of the limit clamp 15 and the limit pin. 9 After separation, the stopper pin can be supported by the clamping plate 16, and the top wall of the clamping plate 16 is attached to the outer wall of the limit shaft 9, and the threaded rod 13 is sleeved with a threaded sliding sleeve 14, and the threaded rod 13 It is connected with the threaded sliding sleeve 14 by...

Embodiment 3

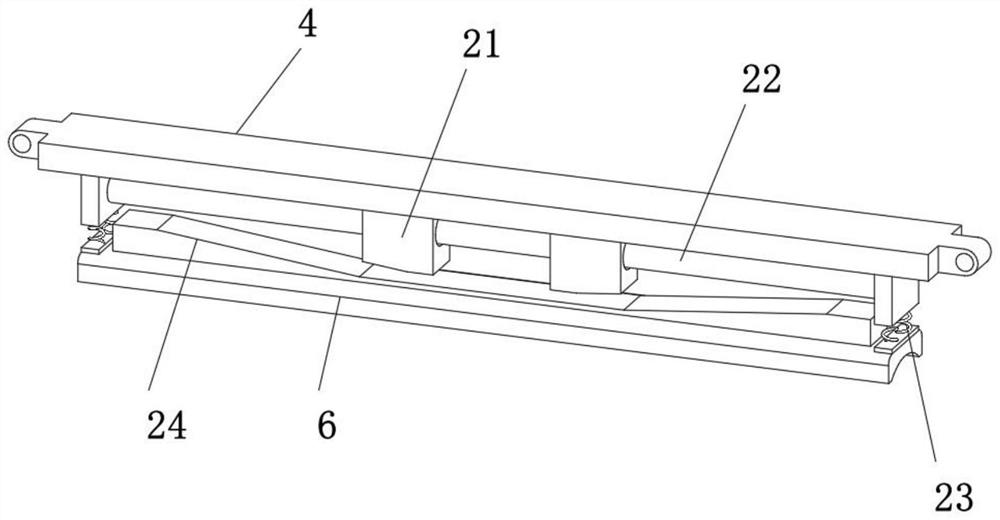

[0044] Example three, please refer to Figure 1-5 , the top of the bottom plate 17 and the opposite side of the cloth roll 18 are provided with a limit roller 7, and the two ends of the limit roller 7 are rotatably connected with the base plate 17 through the support plate 3, wherein the two ends of the limit roller 7 are connected to each other through the rotating shaft. The support plate 3 is rotatably connected, and through the setting of the limit roller 7, the friction between the cloth and the support plate 3 during the supply process is reduced to ensure the quality during transportation. A movable cover is set directly above the limit roller 7 4. One end of the movable cover 4 is rotatably connected to the support plate 3 through the pin shaft, and the other end is rotatably connected to the support plate 3 through the pull pin 8, realizing the function that the movable cover 4 can rotate around the top of the support plate 3 through the pin shaft , wherein the plug-i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com