Method and device of elbow pipe angle detection

A technology of angle detection and pipe bending, which is applied in the field of machinery and electronics, can solve the problems of large errors and time-consuming, and achieve the effect of solving errors, low environmental requirements, and improving accuracy and efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

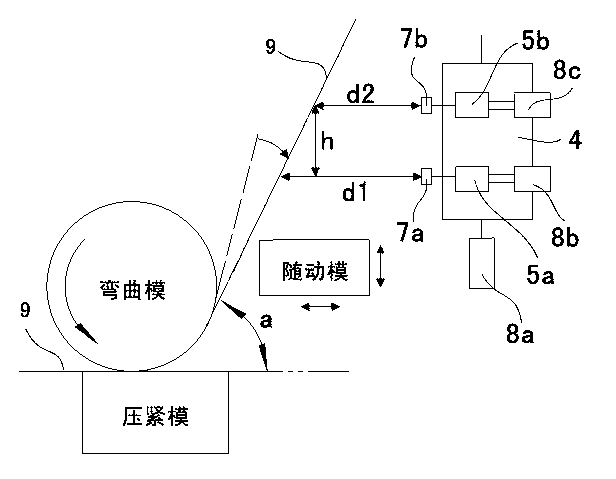

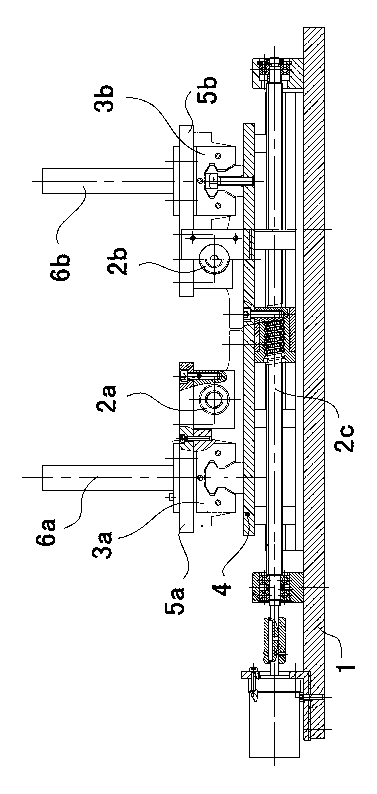

[0030] see Figure 1 to Figure 6 , a method for detecting the angle of a pipe bend. When a pipe bender bends a pipe, a section of the pipe bend 9 needs to be relatively fixed. This section is called the fixed section, and the section to be bent is called the bending section. It is called the included angle section, and it forms a certain included angle with the fixed section. This method detects the angle of the included angle,

[0031] Step 1, two sensors 7a, 7b are arranged beside the angled section of the elbow 9;

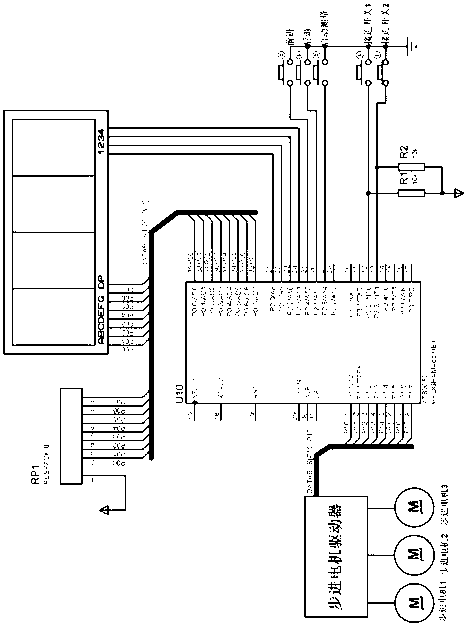

[0032] Step 2, after the bending section of the elbow 9 is removed from the external force and the rebound is stable, use the first stepping motor 8a and the second stepping motor 8b to drive the probes of the two sensors 7a and 7b to measure two or more different points in the angle section position information, and send the position information to the single-chip microcomputer, the single-chip microcomputer completes the calculation and displays the angle inf...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com