Novel pneumatic-type mold extraction device

A pneumatic, new type of technology, applied in the direction of casting molds, cores, molding machines, etc., can solve problems such as the influence of the core process of the hot core box core shooting machine, and achieve the effects of saving manpower, convenient use and realizing automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

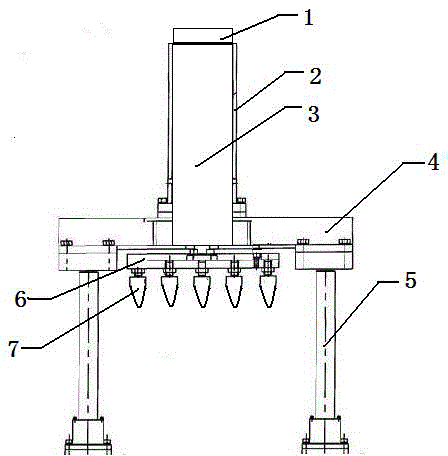

[0011] This embodiment provides a new pneumatic mold drawing device, which is characterized in that: the pneumatic new mold drawing device includes a piston head (1), a pneumatic cylinder (2), a piston rod (3), a mounting frame ( 4), column (5), support frame (6), drawer (7);

[0012] Among them: a pneumatic cylinder (2) is arranged on the installation frame (4), the upper end of the pneumatic cylinder (2) is a piston head (1), and the piston rod (3) of the pneumatic cylinder (2) is connected with a support frame (6), 5 drawer parts (7) are installed on the support frame (6), and support columns (5) are symmetrically arranged on both sides of the installation frame (4).

[0013] Its working process is: just fix it in any direction around the core box, and then make the pneumatic cylinder (2) stretch out to drive the support frame (6) to move forward, so that the mold drawing on the support frame (6) The piece (7) is in contact with the sand core in the core box, and then the ...

Embodiment 2

[0015] A new pneumatic mold drawing device, characterized in that: the pneumatic new mold drawing device includes a piston head (1), a pneumatic cylinder (2), a piston rod (3), an installation frame (4), a column ( 5), support frame (6), drawer (7);

[0016] Among them: a pneumatic cylinder (2) is arranged on the installation frame (4), the upper end of the pneumatic cylinder (2) is a piston head (1), and the piston rod (3) of the pneumatic cylinder (2) is connected with a support frame (6), 10 drawer parts (7) are installed on the support frame (6), and support columns (5) are symmetrically arranged on both sides of the installation frame (4).

[0017] Its working process is: just fix it in any direction around the core box, and then make the pneumatic cylinder (2) stretch out to drive the support frame (6) to move forward, so that the mold drawing on the support frame (6) The piece (7) is in contact with the sand core in the core box, and then the piston rod (3) of the pneu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com