Hole drilling tooling

A drilling tool and drill bit technology, which is applied in the direction of the driving device, drill pipe, and drill pipe for drilling in the borehole, can solve the problems of high labor intensity, low degree of mechanization, and low work efficiency, and achieve good protection effect. The effect of high degree of automation and high applicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

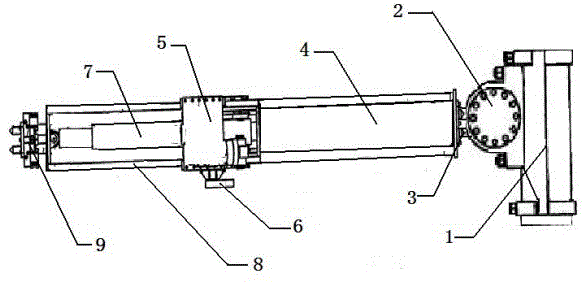

[0012] This embodiment provides a drilling tool, which is characterized in that: the drilling tool includes a mounting seat (1), a motor output shaft (2), a connecting seat (3), a first oil cylinder (4), a connecting bearing (5), oil port (6), second oil cylinder (7), protective sleeve (8), drill bit (9);

[0013] Among them: the device includes a supporting device, a power mechanism and a feeding device, the supporting device is a mounting base (1), and the motor output shaft (2) is sleeve-type installed on the mounting base (1), and one side of the motor output shaft (2) passes through The sliding connection seat (3) is connected to the protective cover (8) of the feeding device. The protective cover (8) is made of high-hardness steel, and the first oil cylinder (4) and the second oil cylinder (7) are arranged inside the protective cover (8). A connecting bearing (5) is provided between the first oil cylinder (4) and the second oil cylinder (7), and an oil port (6) is provid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com