A self-demulsifying heavy oil viscosity reducer and its preparation method and application

A heavy oil viscosity reducer and demulsification technology, applied in chemical instruments and methods, earthwork drilling, wellbore/well components, etc. Molecular weight decline and other problems, to achieve the effect of simple and easy synthesis method, improved oil recovery rate, and large molecular weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

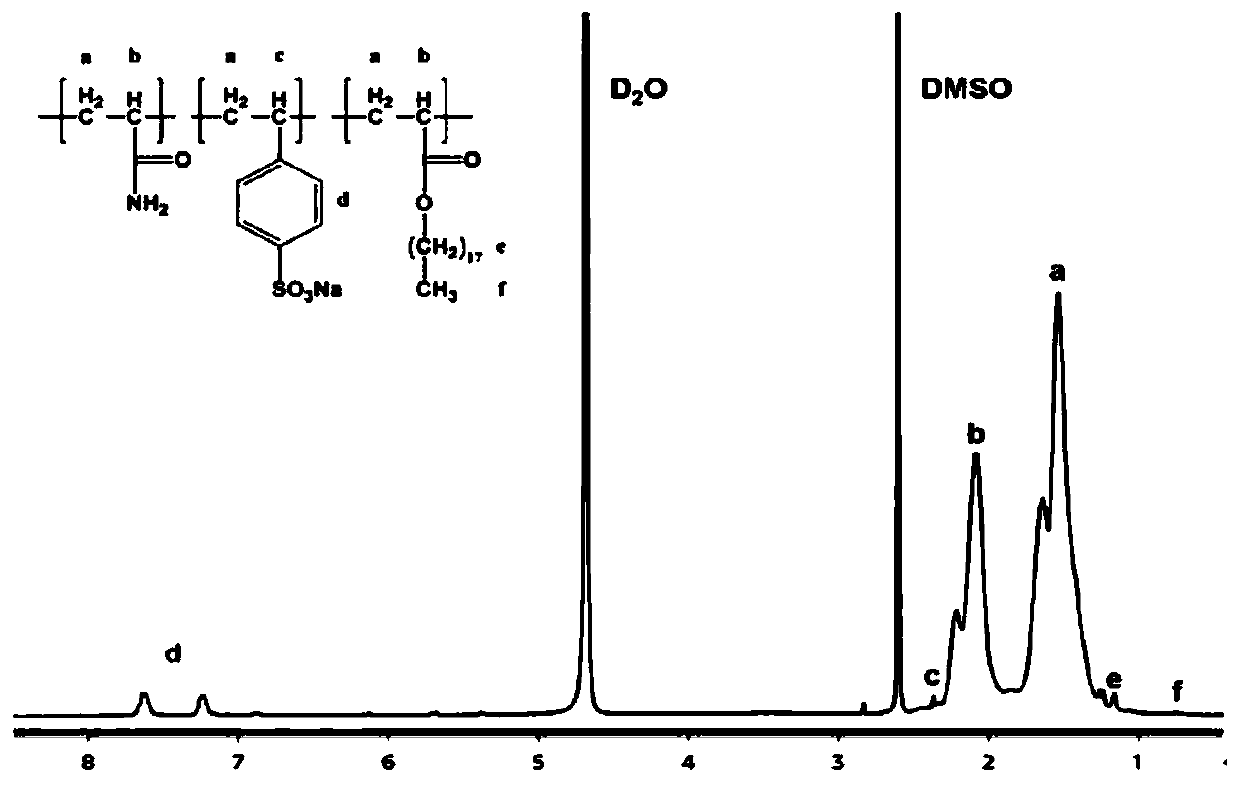

[0062] A self-demulsifying heavy oil viscosity reducer, which is obtained by copolymerizing the following monomers:

[0063] Acrylamide 97.8 mol%

[0064] Sodium p-styrene sulfonate 2 mol%

[0065] Octadecyl acrylate 0.2 mol%.

[0066] The preparation method of the above-mentioned self-demulsifying heavy oil viscosity reducer comprises steps:

[0067] (1) Weigh 13.90g of acrylamide, 0.82g of sodium p-styrenesulfonate and 0.13g of stearyl acrylate into a container, add 66.20mL of dimethyl sulfoxide, stir at 50°C for 5min, and wait until the raw materials are completely Dissolve; after the raw material is completely dissolved, inject nitrogen gas, stir at 50°C for 30 minutes, and make it completely in the nitrogen atmosphere to obtain the raw material solution;

[0068] (2) Under nitrogen atmosphere, heat up to 70°C, then add 0.0743g of initiator azobisisobutyronitrile, and react for 7h at 70°C under nitrogen protection; after the reaction, the product is precipitated and was...

Embodiment 2

[0085] A self-demulsifying heavy oil viscosity reducer, which is obtained by copolymerizing the following monomers:

[0086] Acrylamide 97.6 mol%

[0087] Sodium p-styrene sulfonate 2 mol%

[0088] Octadecyl Acrylate 0.4 mol%.

[0089] The preparation method of the above-mentioned self-demulsifying heavy oil viscosity reducer comprises steps:

[0090] (1) Weigh 13.87g of acrylamide, 0.82g of sodium p-styrene sulfonate and 0.26g of stearyl acrylate into a container, add 66.20mL of dimethyl sulfoxide, stir at 50°C for 5min, and wait until the raw materials are completely Dissolve; after the raw material is completely dissolved, inject nitrogen gas, stir at 50°C for 30 minutes, and make it completely in the nitrogen atmosphere to obtain the raw material solution;

[0091] (2) Under nitrogen atmosphere, heat up to 70°C, then add 0.0747g of initiator azobisisobutyronitrile, and react for 7h at 70°C under nitrogen protection; after the reaction, precipitate and wash the product w...

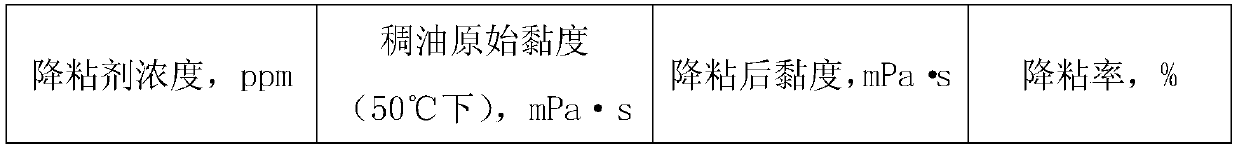

Embodiment 3

[0107] A self-demulsifying heavy oil viscosity reducer, which is obtained by copolymerizing the following monomers:

[0108] Acrylamide 97.5 mol%

[0109] Sodium p-styrene sulfonate 2 mol%

[0110] Octadecyl acrylate 0.5 mol%.

[0111] The preparation method of the above-mentioned self-demulsifying heavy oil viscosity reducer comprises steps:

[0112] (1) Weigh 13.85g of acrylamide, 0.82g of sodium p-styrenesulfonate and 0.325g of stearyl acrylate into a container, add 66.20mL of dimethyl sulfoxide, stir at 50°C for 5min, and wait until the raw materials are completely Dissolve; after the raw material is completely dissolved, inject nitrogen gas, stir at 50°C for 30 minutes, and make it completely in the nitrogen atmosphere to obtain the raw material solution;

[0113] (2) Under a nitrogen atmosphere, heat up to 70°C, then add 0.0750 g of initiator azobisisobutyronitrile, and react for 7 hours at 70°C under nitrogen protection; after the reaction, the product is precipitated ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com