An automatic material return device and method

A technology of material return and driving mechanism, which is applied in the direction of assembly machines, metal processing equipment, manufacturing tools, etc., can solve the problems of inconvenient material return, and achieve the effects of preventing unrelated personnel from operating, low error rate, and convenient input mode

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

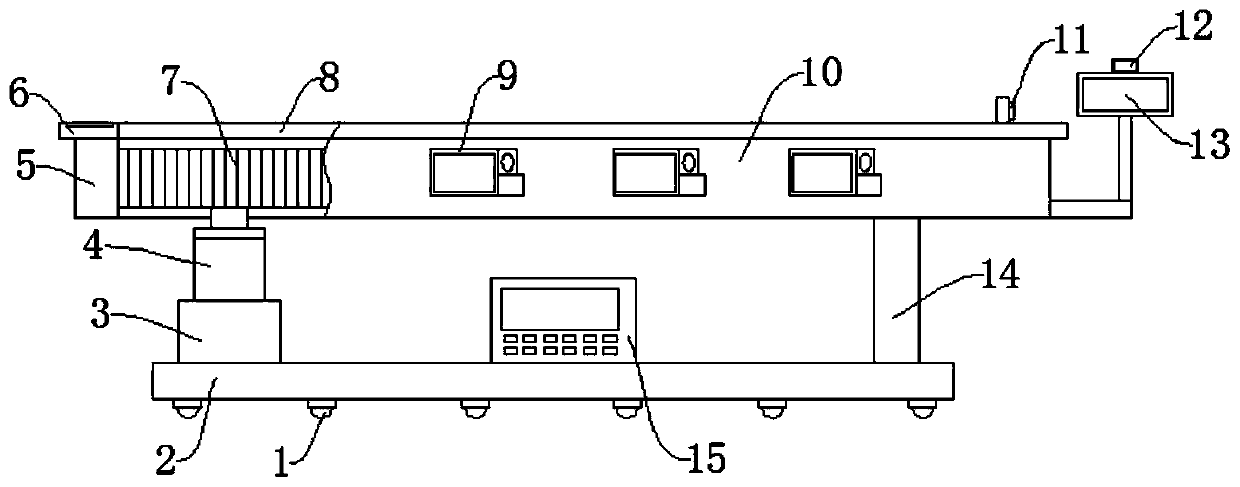

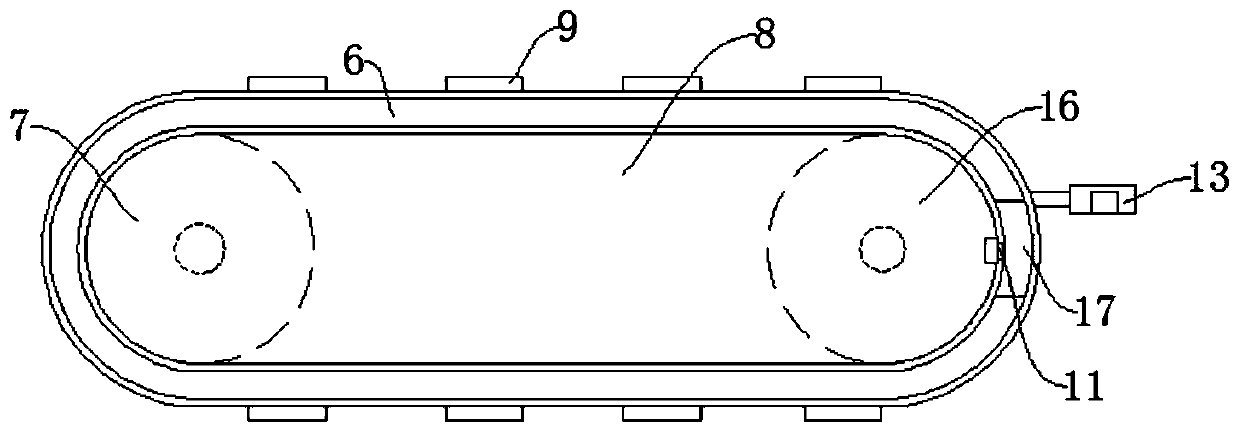

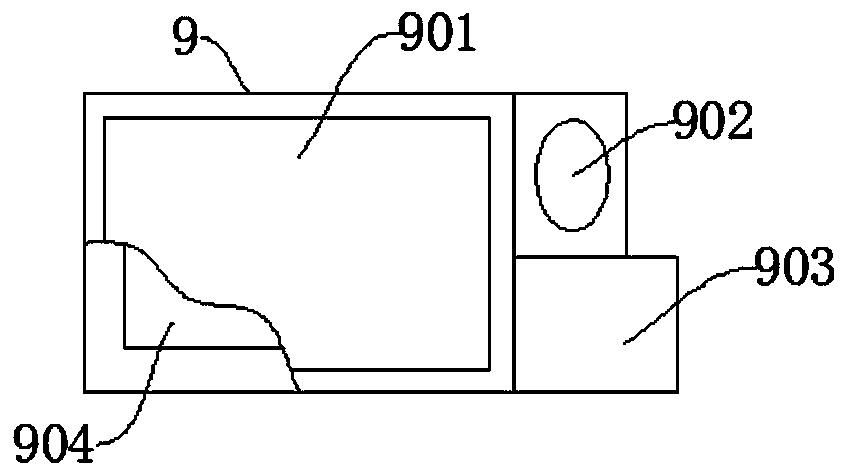

[0036] combine figure 1 and figure 2 , an automatic material return device in this embodiment includes a frame 2, a main controller 15, a conveyor belt 6 mounted on the frame 2, and a driving mechanism for driving the conveyor belt 6 to move. Specifically, the driving mechanism includes a motor 4, a driving wheel 7, a driven wheel 16, and a synchronous belt 5. The motor 4 is electrically connected to the main controller 15 arranged on the frame 2, and the main controller 15 is provided with a control panel. The working state of the motor 4, including its rotational speed, can be controlled. One side of frame 2 is provided with backing plate 3, and the other side is provided with supporting shaft 14, and motor 4 is located on backing plate 3, and driving wheel 7 is connected to the output end of motor 4, and driven wheel 16 is rotatably arranged by bearing. On the support shaft 14 , the rotation axes of the driving wheel 7 and the driven wheel 16 are all perpendicular to the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com