Plastic bottle washing machine

A bottle washing machine and plastic bottle technology, which is applied in the field of washing machines, can solve problems such as difficulty in ensuring operational stability, failure to meet the requirements of high output, and production line pull, etc., to achieve convenient debugging and maintenance, compact structural design, and stable production and operation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

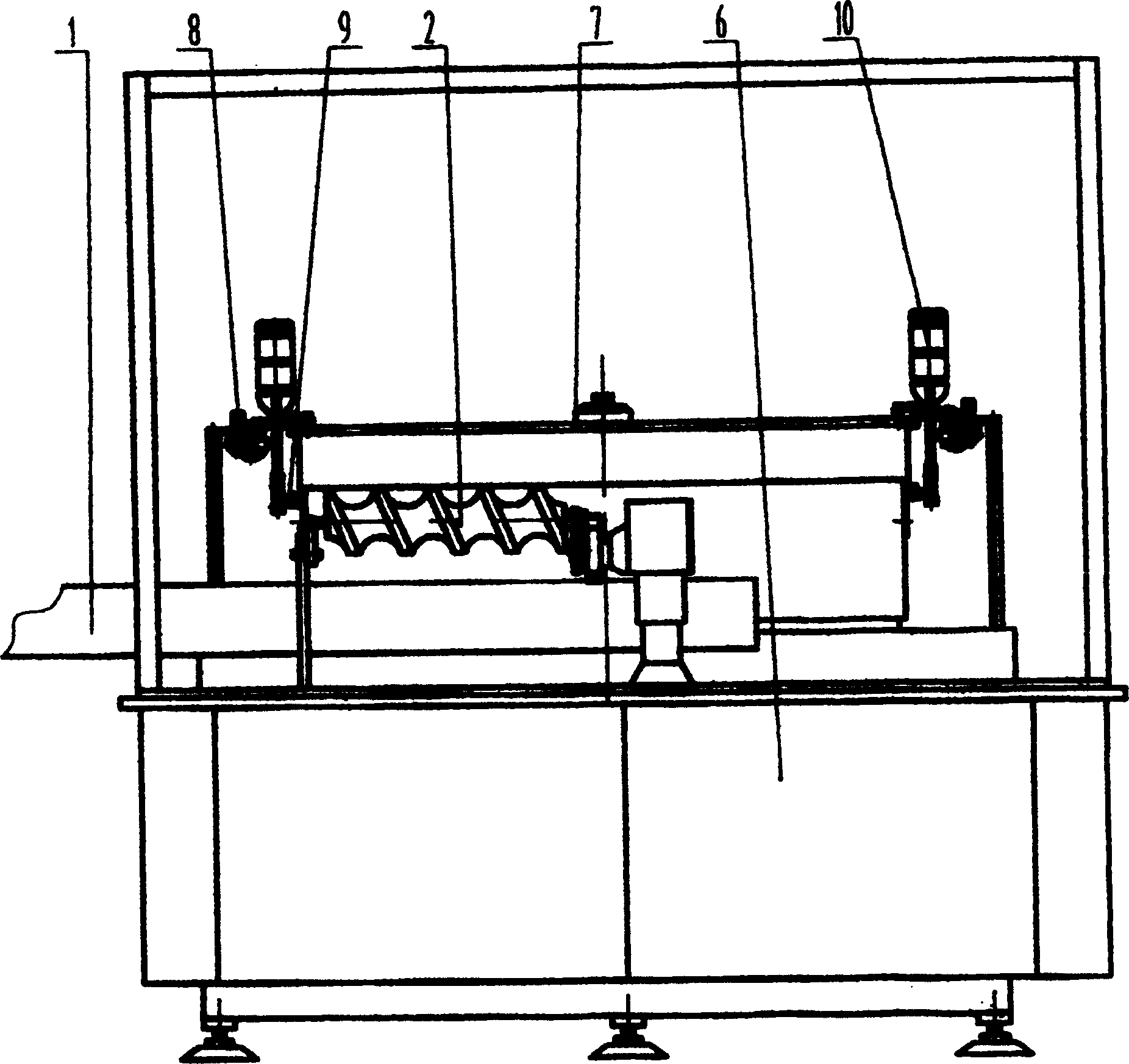

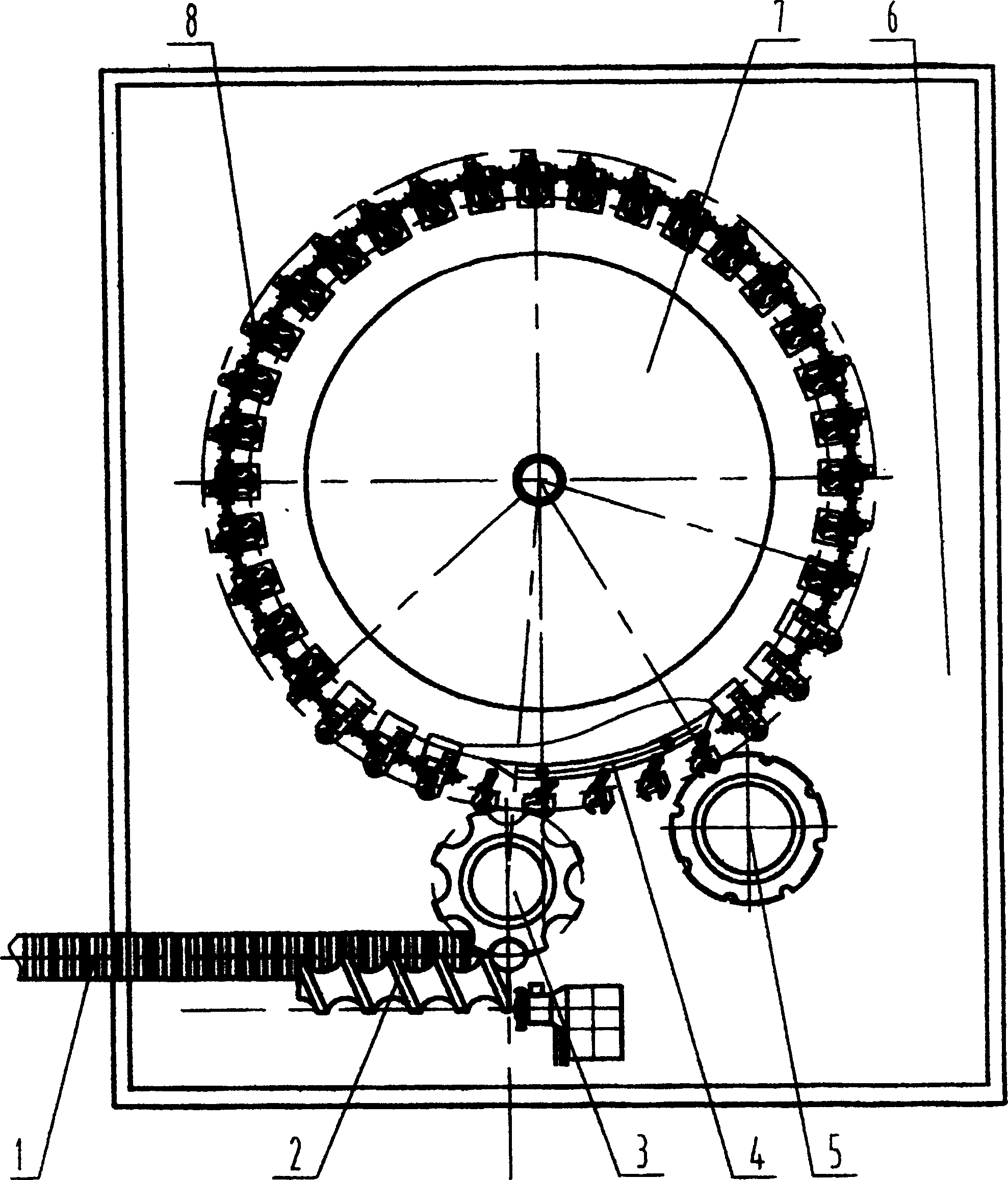

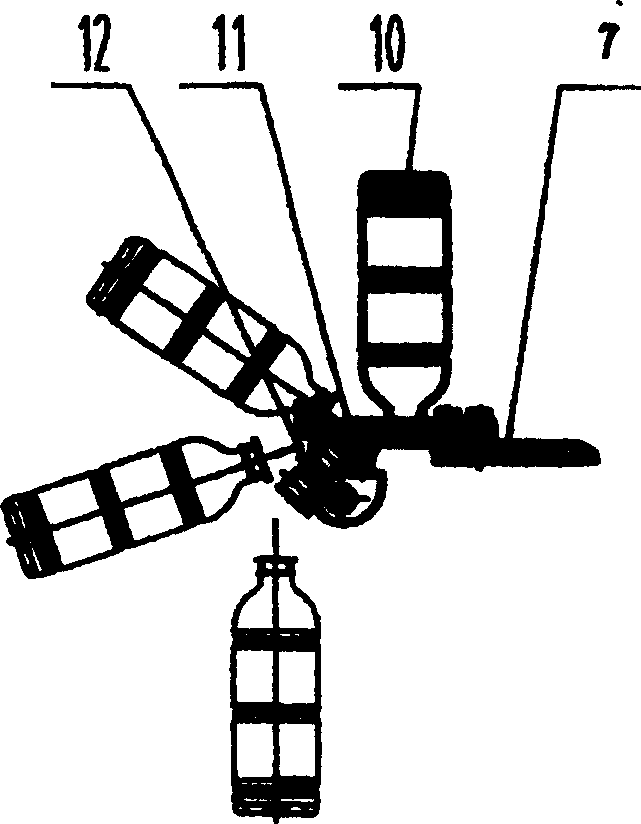

[0014] Such as figure 1 , figure 2 As shown, the present invention is characterized in that it includes a bottle-feeding bottle track 1, a bottle-feeding auger part 2, a bottle-feeding dial part 3, a manipulator opening and closing part 4, a bottle-out dial part 5, and a frame part 6 , rotating part 7, manipulator overturning part 8, tracking washing part 9, the described bottle feeding and transporting track 1 is a general-purpose bottle transporting track, which can complete the work of transporting bottles from front to back, and one end is fixedly connected to the frame 6, the other end is supported on the ground with a foot. Be provided with bottle feeding auger part 2 on the bottle feeding track 1, it is a general auger part, can finish the bottle equidistant that comes in on the bottle feeding track 1 and send in the dial wheel of bottle feeding dial part 3. The bottle-feeding dial part 3 is a directional rotating part, located between the bottle-feeding auger part 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com