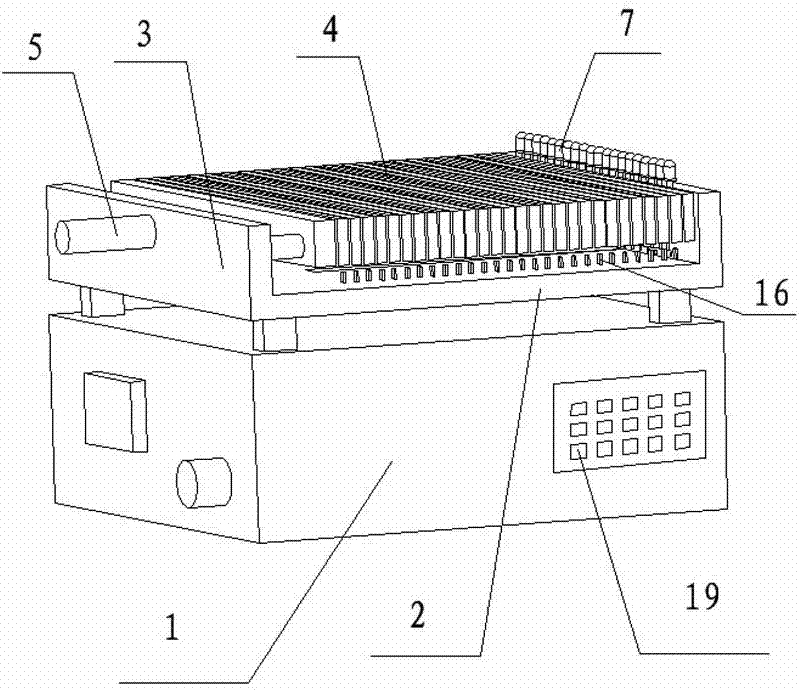

LED (Light Emitting Diode) ageing detection screening equipment and method

The technology of screening equipment and splint is applied in the field of LED aging detection screening equipment and its detection and screening. Simple and novel structure, improved detection efficiency and detection quantity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

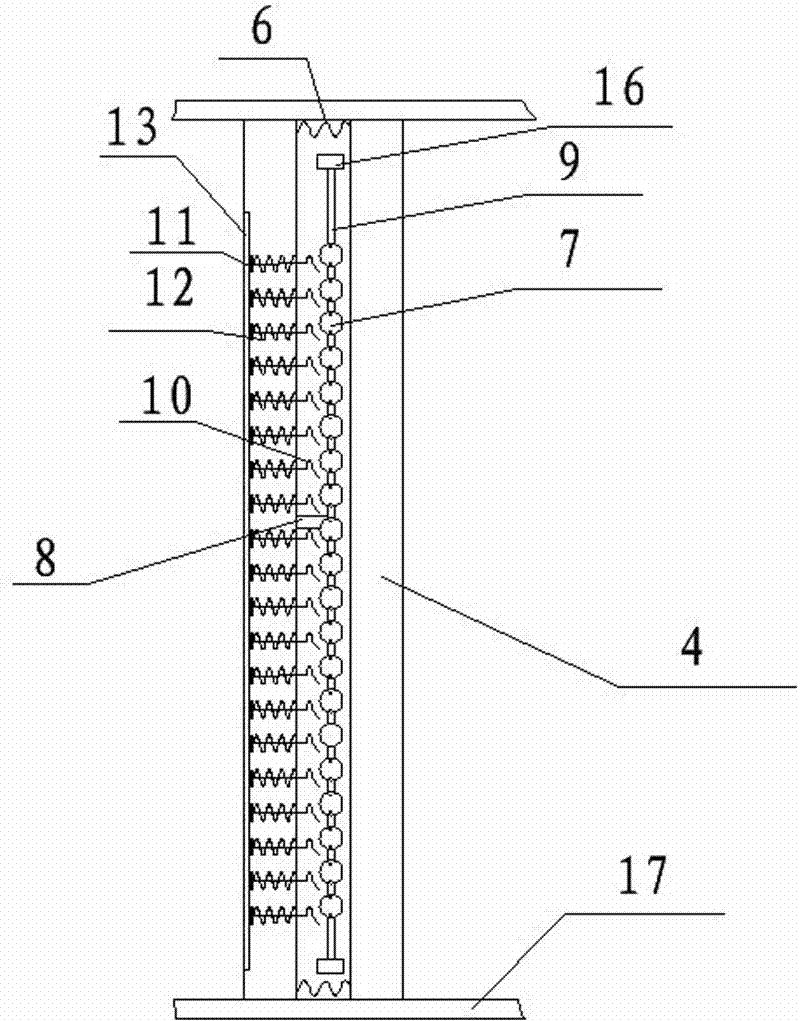

Examples

Embodiment 2

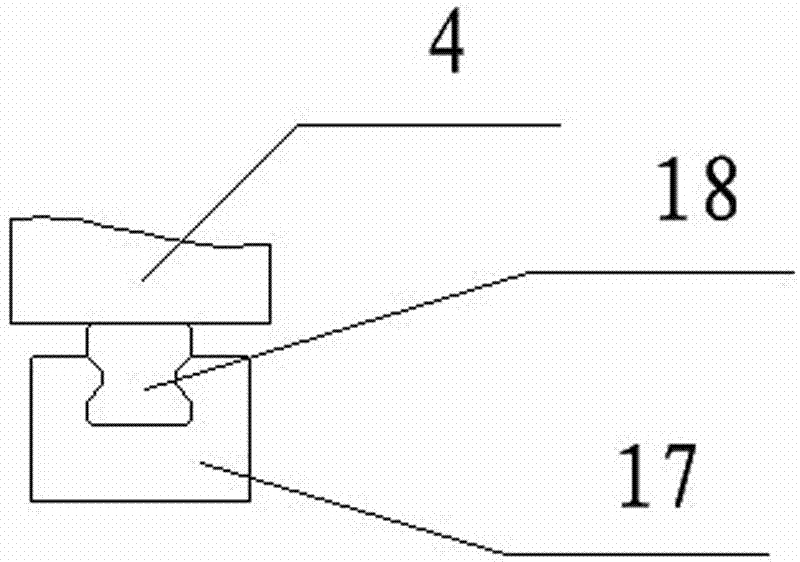

[0032] This embodiment 2 is changed on the basis of embodiment 1, which basically increases the setting of the positive contact piece 14 and the second positive contact piece 15 on the basis of embodiment 1, specifically: as Figure 4 As shown, the splint is also provided with an elastic positive contact piece with the same structure as the negative contact piece, the positive contact piece corresponds to the positive pin of the LED, and the splint is provided with a second positive contact piece corresponding to the positive contact piece. Because the positive current and voltage input by the first positive contact to each LED are different, there are different strengths, and the function of the positive contact and the second positive contact is to increase the current and voltage input to the positive pin of the LED. , to ensure the stability of its current and voltage, and sufficient LED luminosity. Likewise, the positive contact strip does not touch the negative pin of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com