Camera module group combined method and camera module group

The technology of a camera module and a combination method, which is applied in the field of photography, can solve the problems of fragile components, poor compatibility between the lens unit and the photosensitive unit, and time-consuming combination, so as to achieve good compatibility, avoid repeated disassembly operations, and improve combination efficiency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

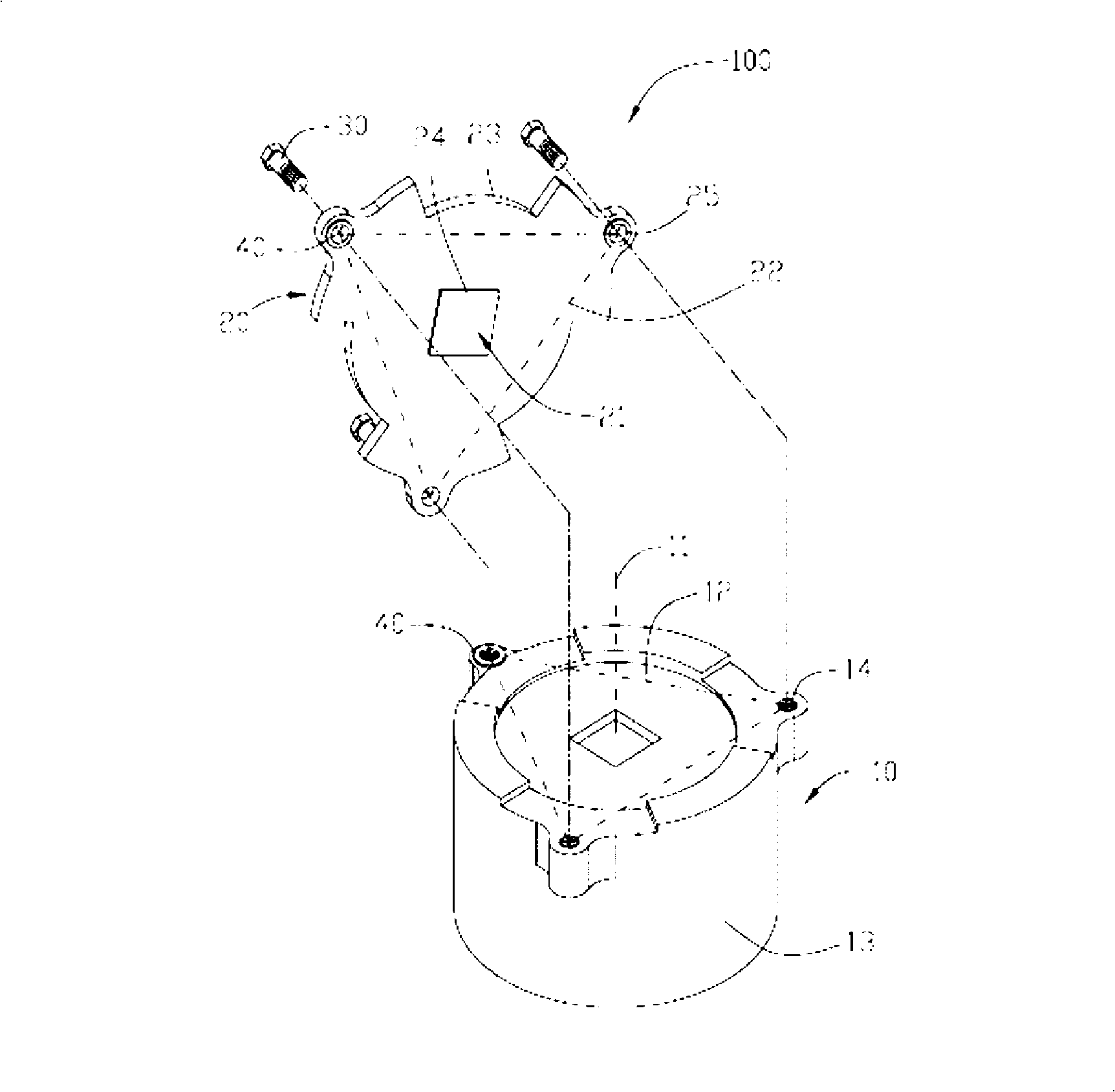

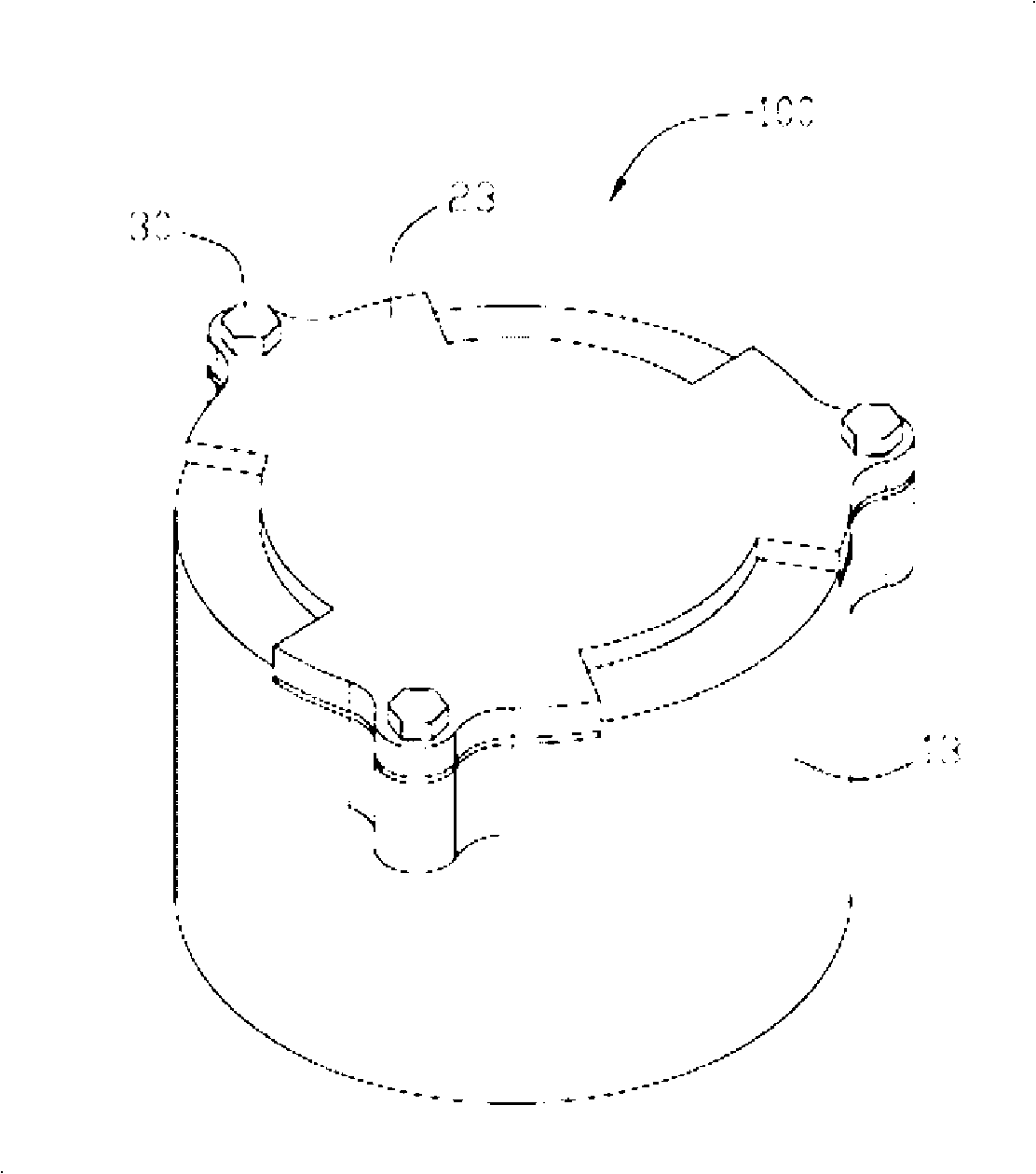

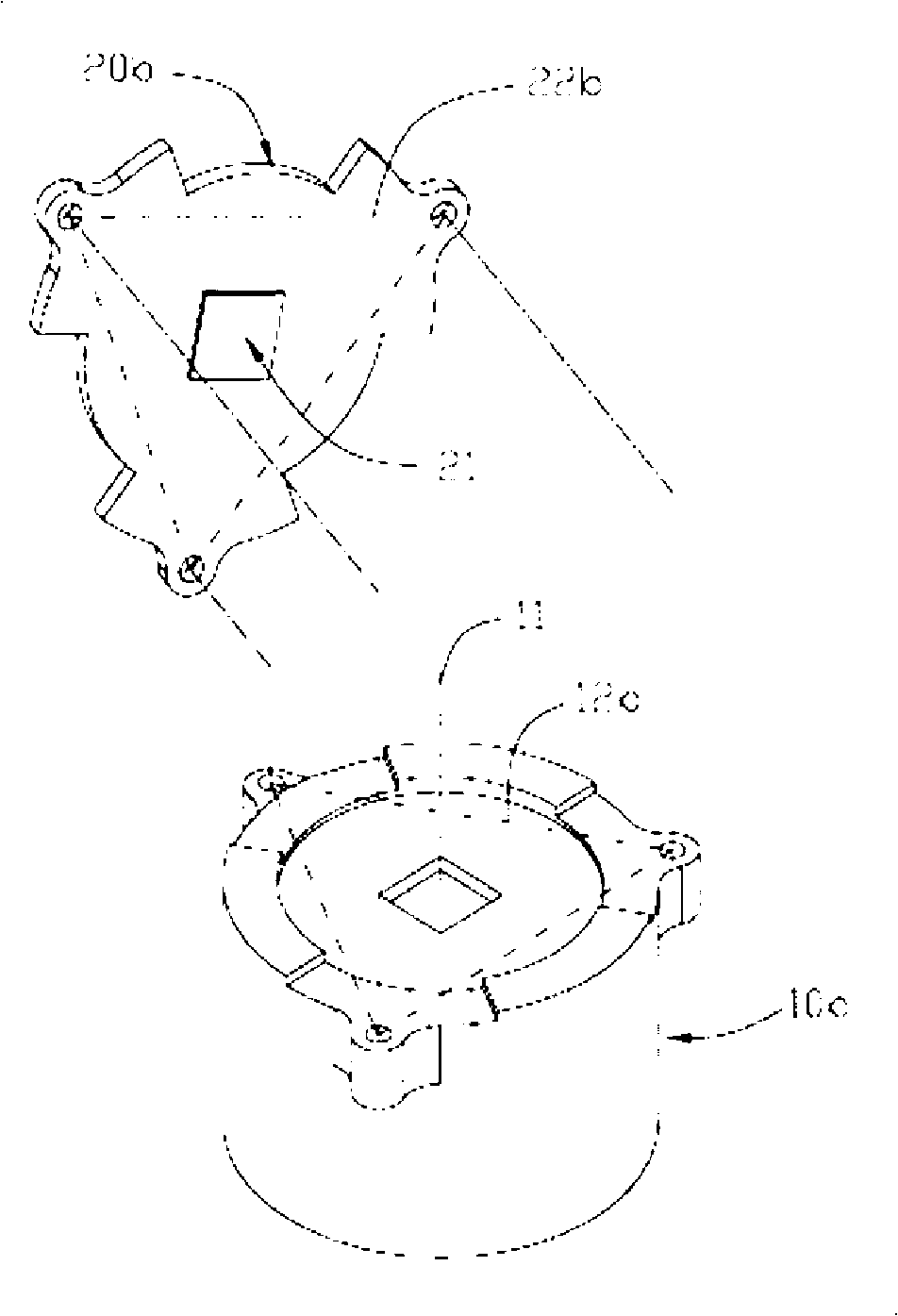

[0019] Please also see figure 1 and figure 2 , the camera module 100 of the preferred embodiment includes a lens unit 10 and a photosensitive unit 20 . The lens unit 10 has an optical axis 11 and a locking surface 12 , the optical axis 11 is perpendicular to the locking surface 12 . The photosensitive unit 20 has a photosensitive surface 21 and an assembly surface 22 , the assembly surface 22 is parallel to the photosensitive surface 21 and locked to the locking surface 11 .

[0020] Specifically, the lens unit 10 includes a lens barrel 13 and a lens group accommodated in the lens barrel 13 , a shutter mechanism, a focusing mechanism, etc. (not shown). The optical axis of the lens group is the optical axis 11 of the lens unit 10 . The end surface of the lens barrel 13 is provided with three screw holes 14 , and the edges of the three screw holes 14 form the locking surface 12 . The photosensitive unit 20 includes an assembly board 23 and an image sensor 24 disposed on the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com