Technology for manufacturing octagonal center driving shaft sleeve of thickener

A production process, center-driven technology, applied in the direction of manufacturing tools, metal processing equipment, welding equipment, etc., can solve the problem of not finding the same or similar technical solutions, improve welding efficiency and welding accuracy, improve operation safety factor, Improve efficiency and the effect of

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

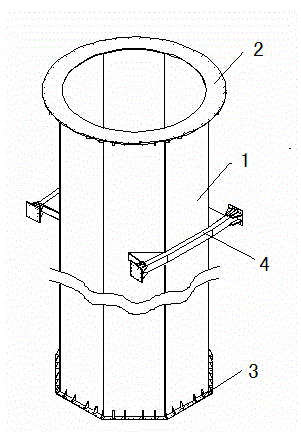

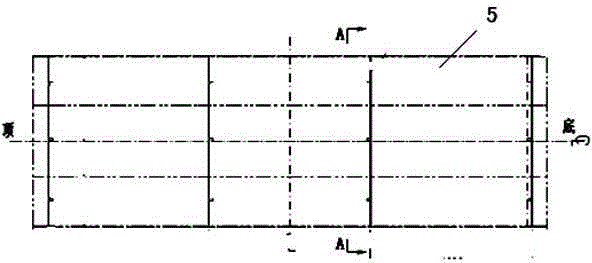

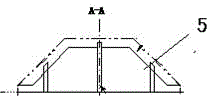

[0027] Such as figure 1 As shown, the present invention relates to an octagonal central drive bushing, the octagonal central drive bushing is formed by sequentially connecting several bushing units up and down, the bushing unit structure is a regular octagonal cylinder 1, the top The top surface and the bottom surface are respectively provided with a top flange plate 2 and a bottom surface flange plate 3, and support truss seats 4 are provided on both sides of the middle and upper part.

[0028] The invention discloses a manufacturing process for manufacturing the above-mentioned octagonal central drive shaft sleeve. Firstly, flat welding is used to manufacture a regular octagonal cylinder body 1, and then the top flange plate 2 is first spliced into one body, and then connected to the upper flange plate after leveling. The bottom flange plates 3 corresponding to a regular octagonal cylinder 1 are drilled in pairs and welded in pairs; the middle support truss seat 4 is first...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com